g-C3N4/graphene composite material and preparation method and application thereof

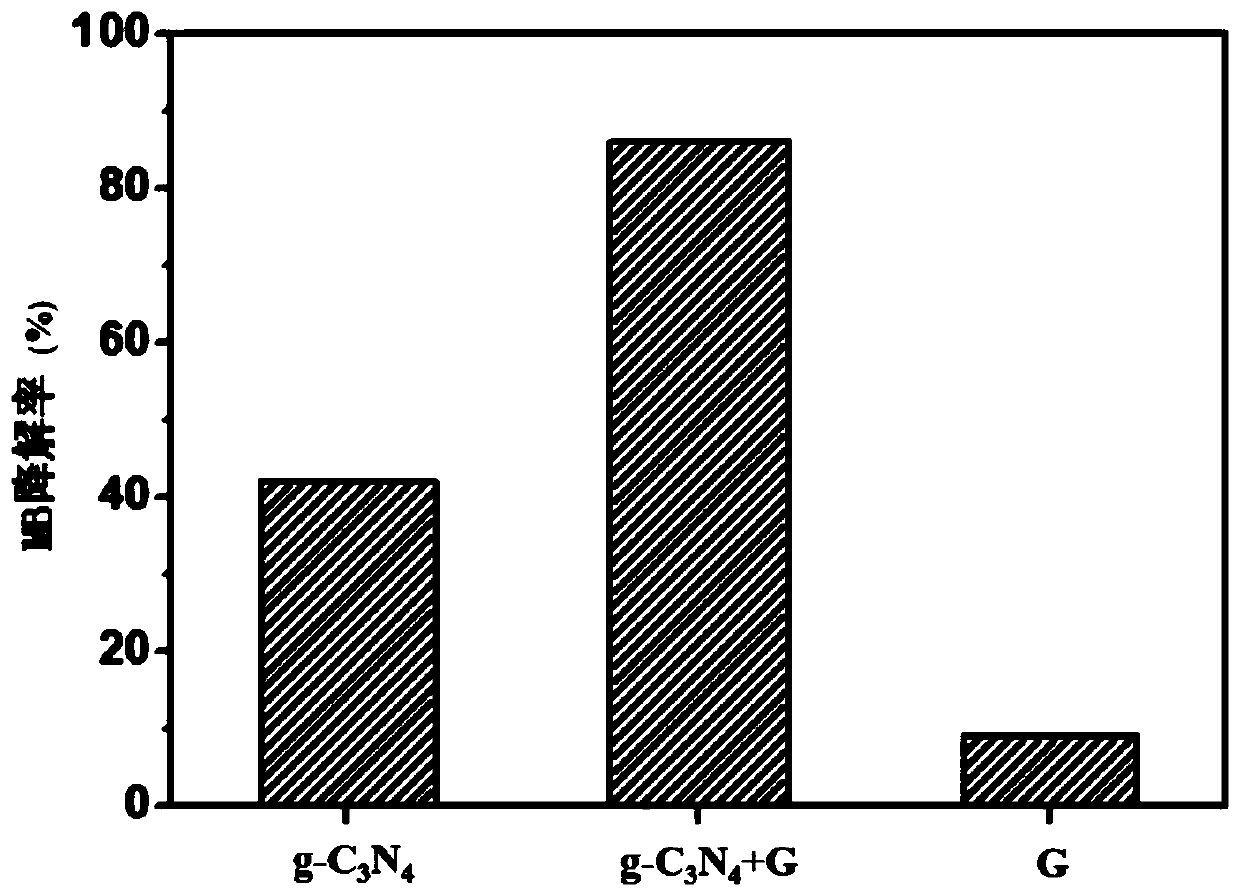

A composite material, g-c3n4 technology, applied in g-C3N4/graphene composite material, in the field of its preparation, can solve the problems of not being able to perform well, the specific surface area of the composite material is small, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] g-C 3 N 4 / The preparation method of graphene composite material, comprises the steps:

[0029] (1) Preparation of g-C 3 N 4 powder:

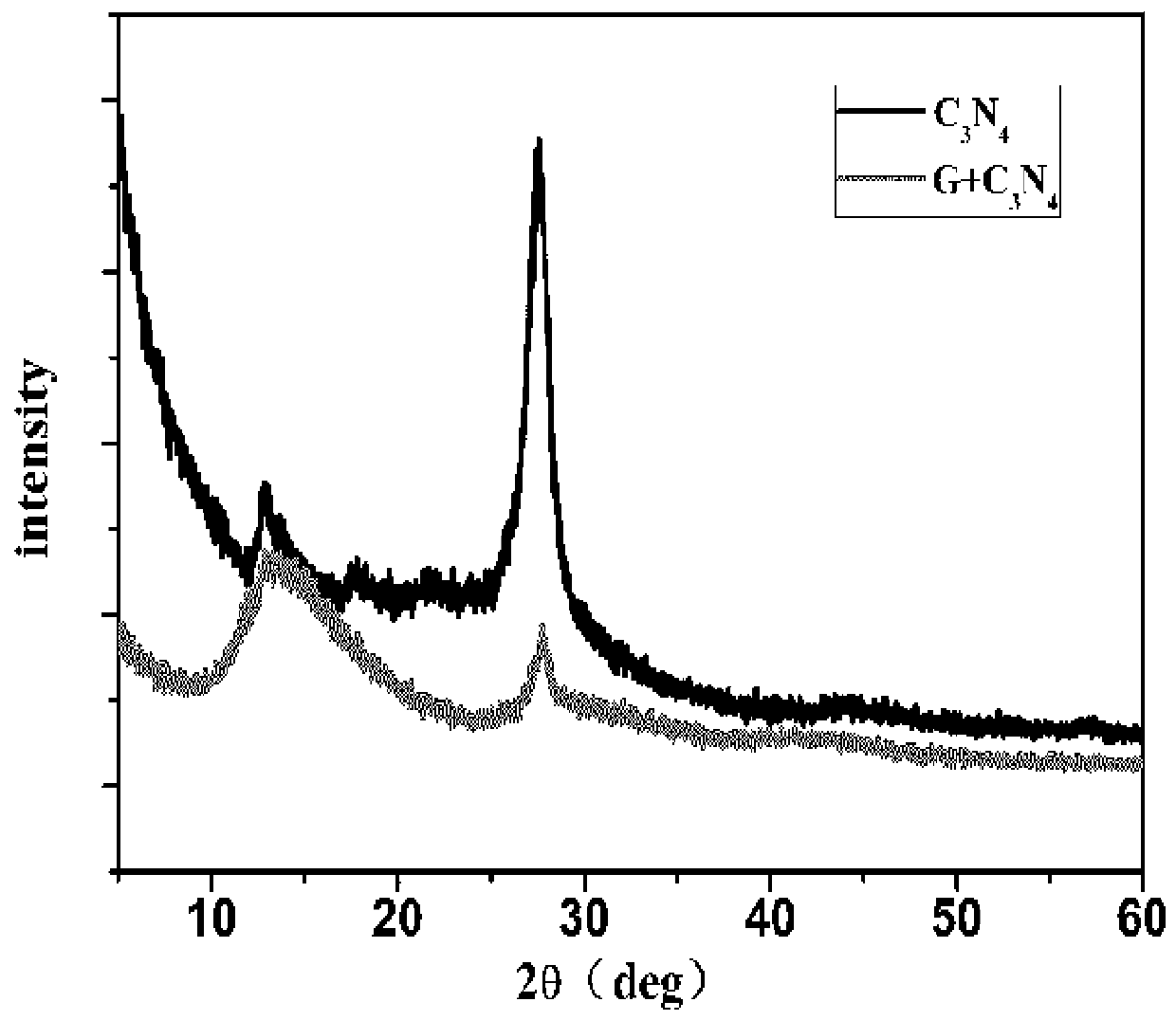

[0030] The nitrogen-containing compound is calcined for the first time at a temperature of 480-520°C for 0.8-1.5h, and then calcined for a second time at a temperature of 530-580°C for 1.5-2.5h to obtain g-C 3 N 4 powder.

[0031] Specifically, weigh a certain amount of melamine and place it in a muffle furnace, heat it at 500°C for 1 hour for the first calcination, and heat it for 2 hours at 550°C for the second calcination to obtain g-C 3 N 4 powder. Among them, the calcination is divided into two times, and the temperature of the first calcination is lower than the temperature of the second calcination, and a relatively loose structure of g-C can be obtained. 3 N 4 powder, also get more g-C 3 N 4 powder.

[0032] Optionally, the nitrogen-containing compound includes one or more of thiourea, dicyandiamine, melamine or urea...

Embodiment 1

[0055] g-C 3 N 4 / The preparation method of graphene composite material, comprises the steps:

[0056] (1) Put melamine in a muffle furnace, perform the first calcination at a temperature of 500°C for 1 hour, and then perform a second calcination at a temperature of 550°C for 2 hours to obtain g-C 3 N 4 powder.

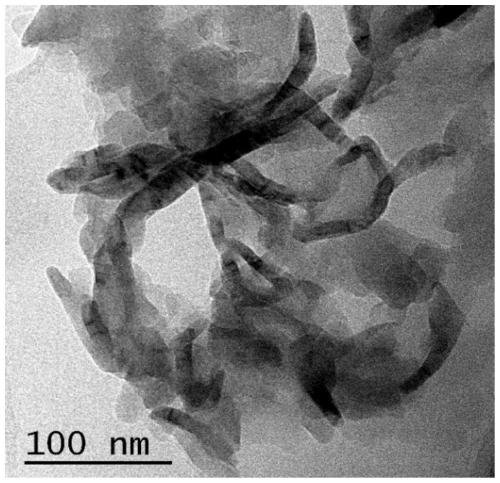

[0057] (2), the g-C 3 N 4 The powder and the graphite powder were dispersed in ethanol water, put into a ball mill for 3 hours, centrifuged, and the solid was taken and dried to obtain a mixed powder. Among them, g-C 3 N 4 The mass ratio of powder and graphite powder is 1:1.

[0058] (3), weigh a certain mass of the above mixed g-C 3 N 4 Put the powder and graphite powder into the mold, add a certain pressure of 15MPa, press the sample under the conditions of 1.5min holding time, and obtain an electrode sheet with a diameter of 1cm and a thickness of 0.5cm.

[0059] (4) Using the electrode sheet as the anode, the platinum wire as the cathode, and the dilute...

Embodiment 2

[0062] g-C 3 N 4 / The preparation method of graphene composite material, comprises the steps:

[0063] (1) Put melamine in a muffle furnace, perform the first calcination at a temperature of 500°C for 1 hour, and then perform a second calcination at a temperature of 550°C for 2 hours to obtain g-C 3 N 4 powder.

[0064] (2), the g-C 3 N 4The powder and graphite powder were put into a ball mill and milled for 3 hours to obtain a mixed powder. Among them, g-C 3 N 4 The mass ratio of powder and graphite powder is 1:1.

[0065] (3), weigh a certain mass of the above mixed g-C 3 N 4 Put the powder and graphite powder into the mold, add a certain pressure of 15MPa, press the sample under the conditions of 1.5min holding time, and obtain an electrode sheet with a diameter of 1cm and a thickness of 0.5cm.

[0066] (4) Using the electrode sheet as the anode, the platinum wire as the cathode, and the dilute sulfuric acid with a concentration of 4mol / L as the electrolyte, perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com