Method for harvesting microalgae and obtaining microalgae biomass

A biomass and microalgae technology, applied in microorganism-based methods, microorganisms, biochemical equipment and methods, etc., can solve the problems of high energy consumption for microalgae harvesting, difficulty in recycling aquaculture water, etc., and achieve green harvesting. , energy saving, strong stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0024] It is well known to those skilled in the art that nitrogen sources (and other nutrients—especially carbon sources) can be added to the culture system in order to obtain higher amounts of microalgal biomass. Therefore, according to a preferred embodiment of the present invention, the method also includes monitoring the nitrogen source (such as NO) in the culture system during the cultivation process. 3 - and / or NO 2 - ) content, so that nitrogen sources (such as NO 3 - and / or NO 2 - ). When nitric acid is used as nitrogen source, the amount of added nitric acid is such that the pH value of the culture system is maintained in the range of 6.5-10 (preferably 7-9.5). The supplementary amount of carbon source (such as glucose) usually makes the content of carbon source in the culture system in the range of 5-10g / L.

[0025] According to a specific embodiment, the method may also include removing NO in the flue gas x converted to NO 3 - and / or NO 2 - , and use it...

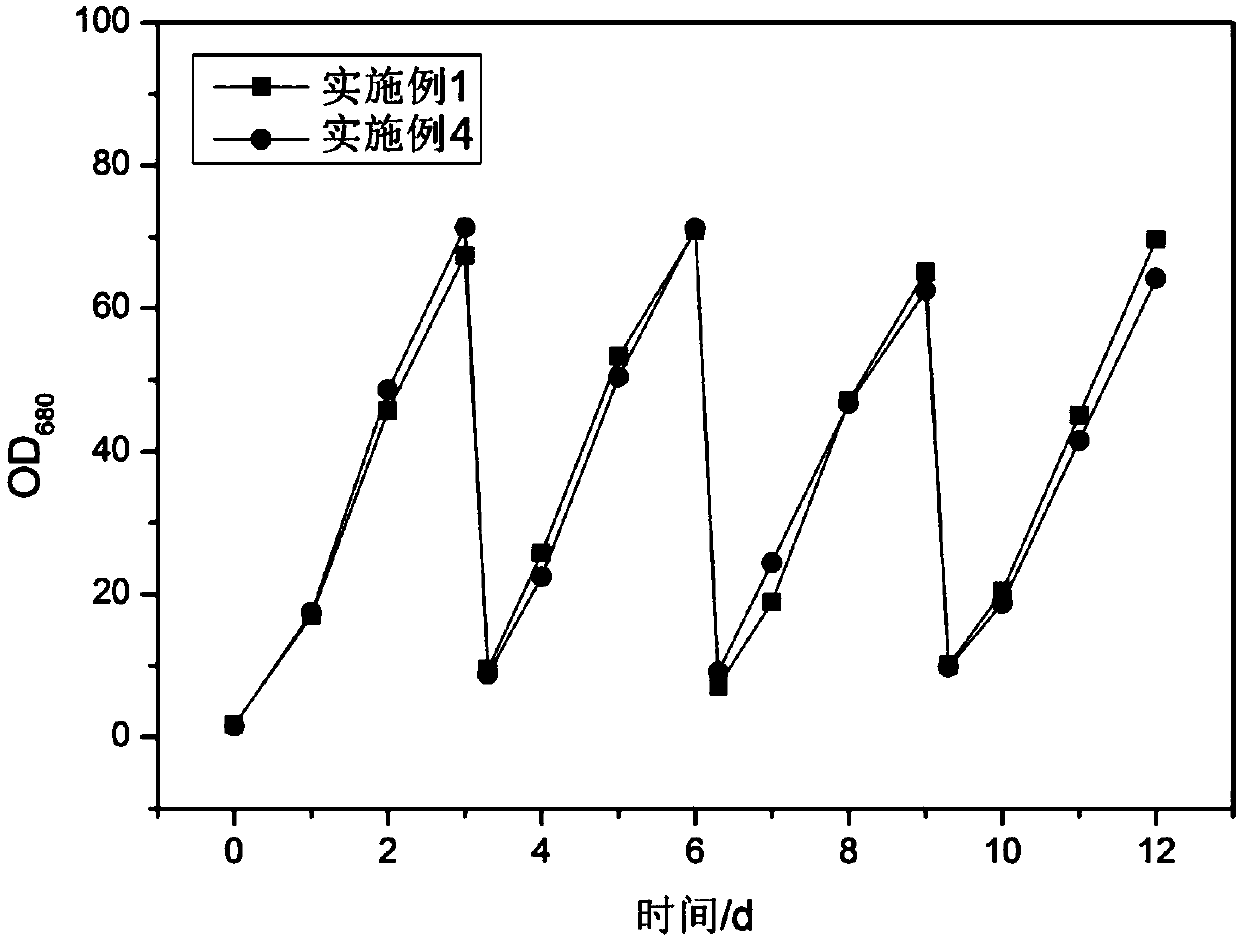

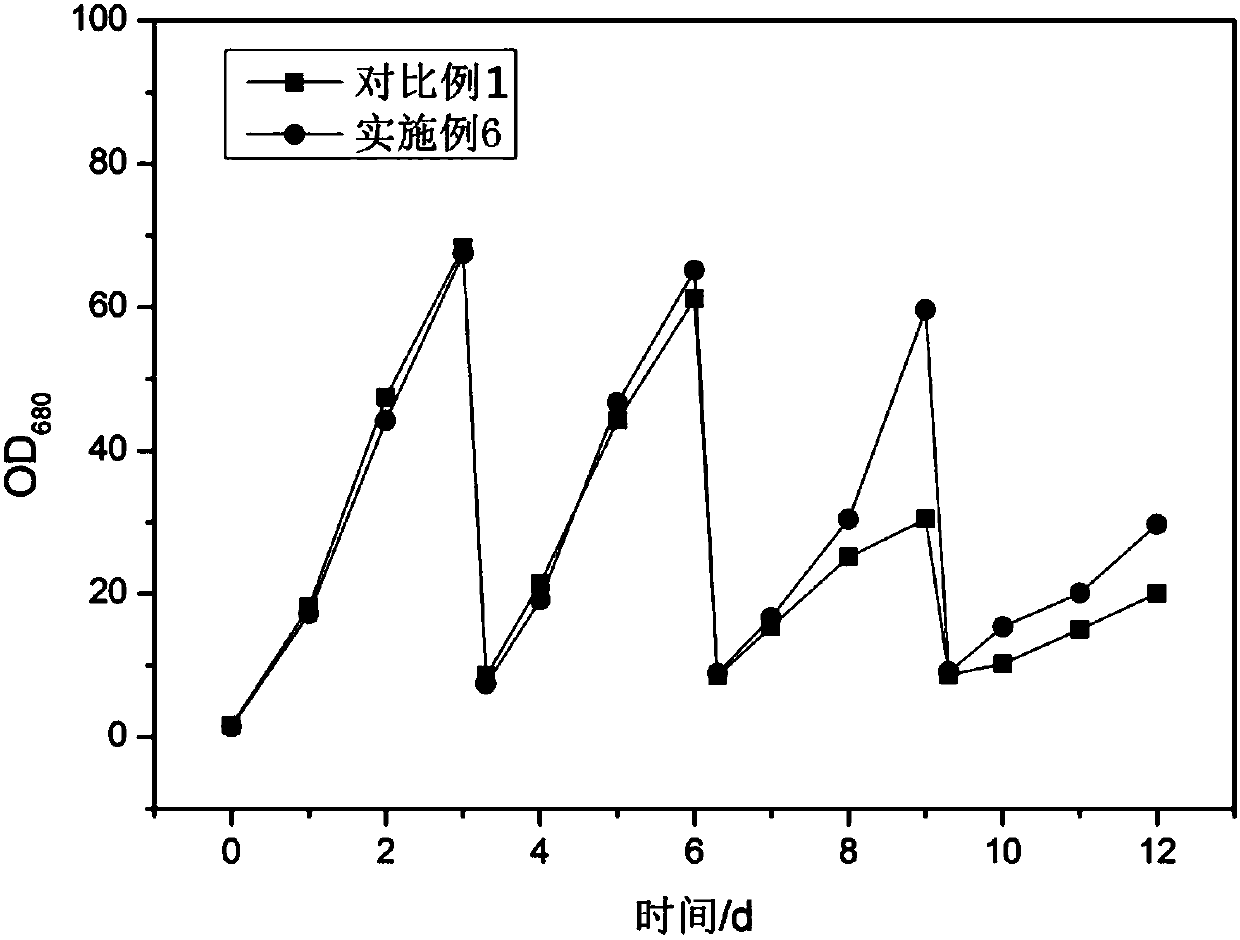

Embodiment 1

[0044] Chlorella species were purchased from the Institute of Hydrobiology, Chinese Academy of Sciences and cultured on BG11 medium. The algae were induced for 2 days in the BG11 medium containing 5g / L glucose, and then inserted into a 5L light fermenter containing 3L BG11 medium for aseptic adjunct culture. After inoculation, the algae liquid OD 680 Control at about 1, culture conditions are: temperature 28°C, ventilation rate about 0.9vvm, stirring speed about 280rpm, light intensity 6000lux, light-dark cycle 12h:12h, adding antibiotics to control bacterial growth (kanamycin 50mg / L and chlorine Mycin 10mg / L), and add 0.1% by volume of antifoaming agent (emulsified silicone oil). During the culturing process, the cell density (based on the absorbance OD at 680nm 680 as an indicator) to monitor, and supplement nutrients according to the growth status of microalgae, so as to control the glucose concentration at 5-10g / L, and the additional nitrogen source is HNO 3 , HNO 3 The...

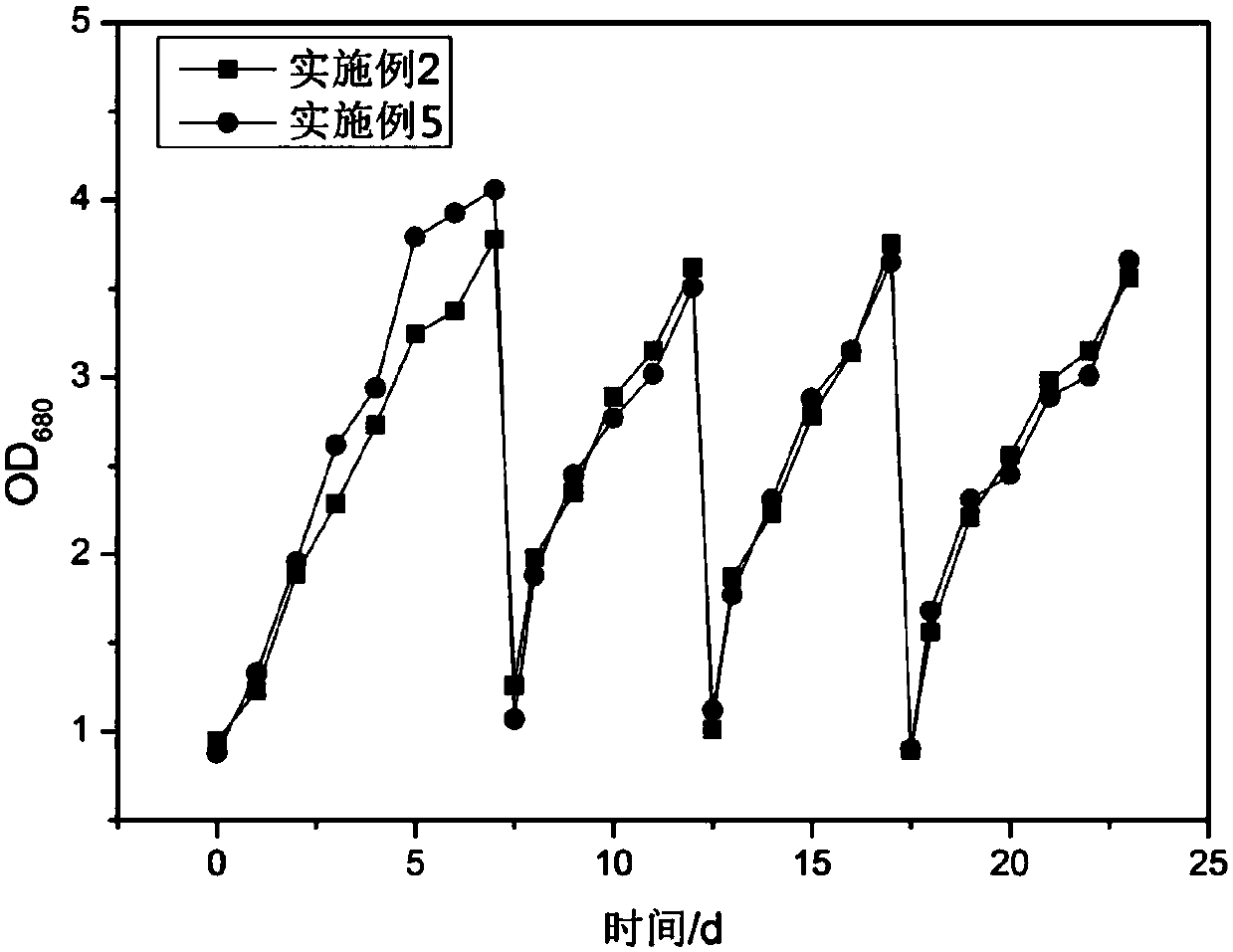

Embodiment 2

[0051] Scenedesmus was purchased from the Institute of Hydrobiology, Chinese Academy of Sciences and cultured on BG11 medium. Add 3LBG11 medium into the 5L Erlenmeyer flask, then inoculate, OD after inoculation 680 The control is about 0.8, and the breeding conditions are: temperature 28°C, ventilation rate 0.8-1vvm, light intensity 6000lux, light-dark cycle 12h:12h, during the breeding process, the cell density (absorbance OD at 680nm 680 as an indicator) to monitor and supplement HNO 3 and other nutrient salts, the pH is controlled between 7-8, and 80% by volume of the algae liquid (the content of microalgae in terms of dry weight is 1.2g / L) is taken out after 7 days of cultivation for membrane filtration. The inlet pressure of the membrane filtration unit is 0.1MPa, the outlet pressure is 0.05MPa, and the molecular weight cut-off of the membrane is 30kDa. The concentrated solution after membrane filtration (the content of microalgae in terms of dry weight is 87g / L) is spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com