Calcium tartrate agent and preparation method thereof

A technology of calcium tartrate and tartaric acid, applied in food ingredients as antioxidants, functions of food ingredients, food science, etc., can solve the problems of low solubility, single efficacy, and insufficient content, and achieve high bioavailability, simple preparation process, The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

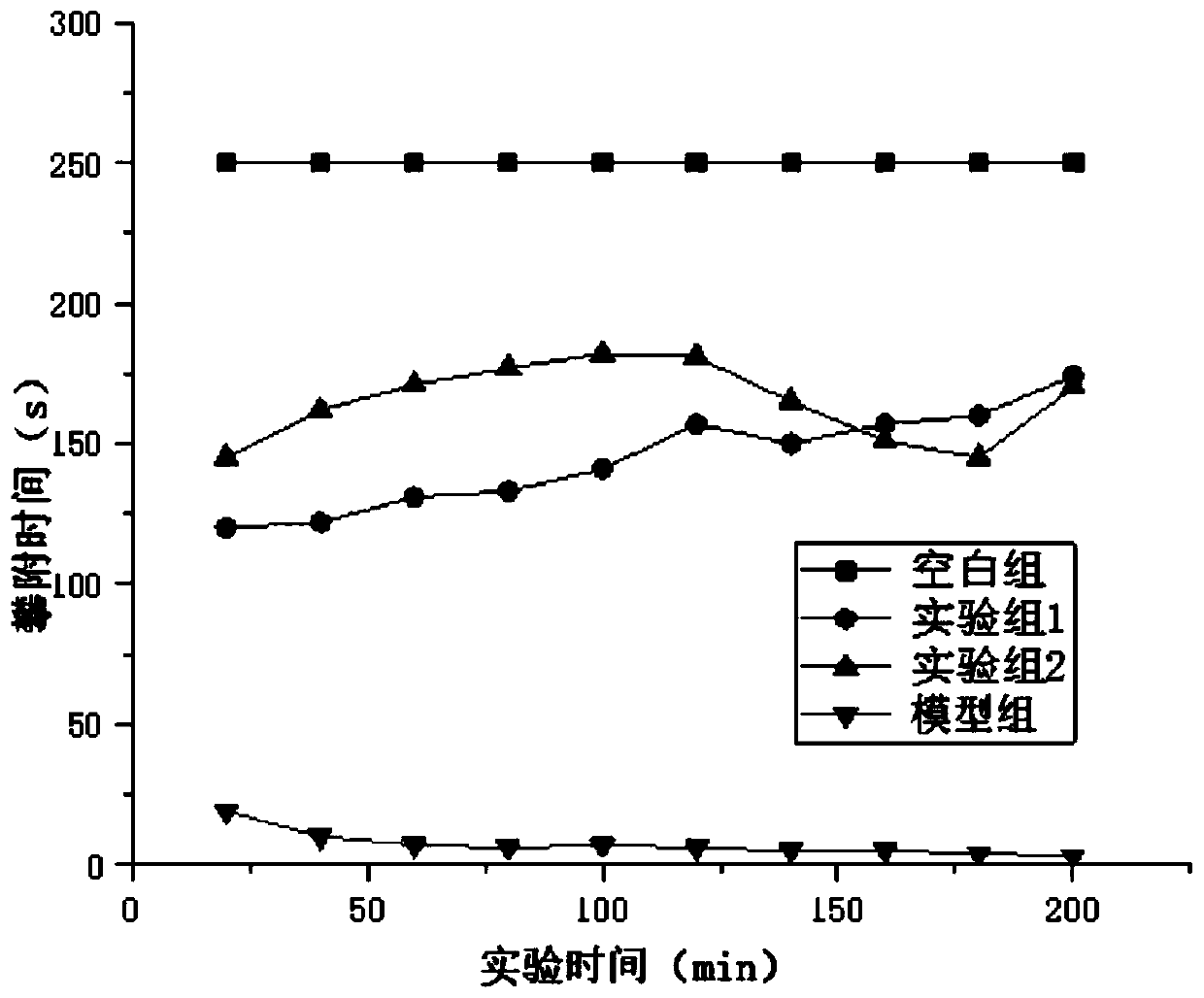

Image

Examples

Embodiment 1

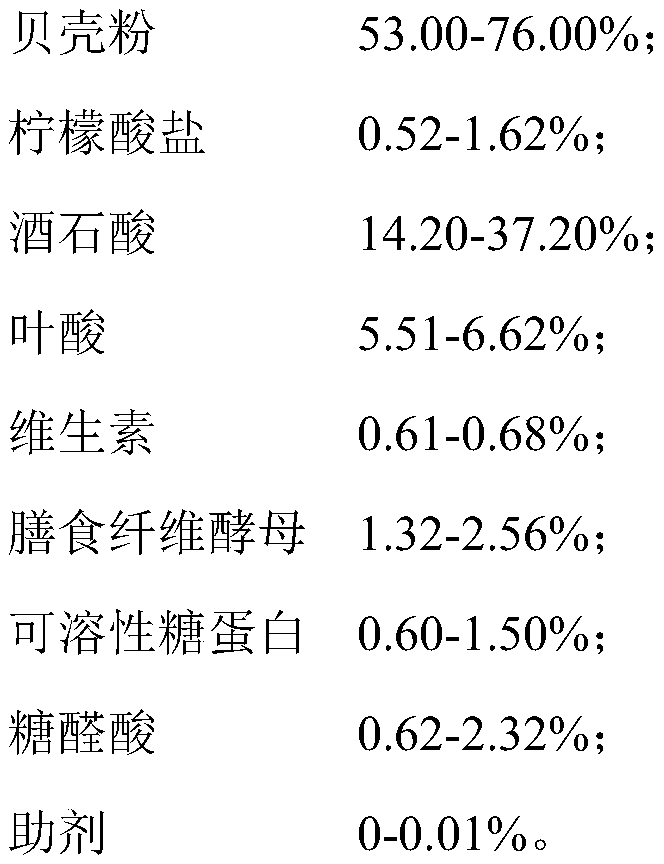

[0031] A kind of calcium tartrate preparation comprises the following components by weight percentage:

[0032]

[0033] The preparation method of above-mentioned calcium tartrate agent, comprises the following steps:

[0034] (1) Tartaric acid, folic acid, D-glucuronic acid, D-galacturonic acid are prepared into aqueous solution respectively, the concentration of tartaric acid aqueous solution, folic acid aqueous solution, D-glucuronic acid aqueous solution, D-galacturonic acid aqueous solution is 10%; the shells were soaked in 0.8% hydrochloric acid for 50 minutes, then washed with water, dried, and then calcined at 350°C for 10 minutes, 650°C for 25 minutes, and 950°C for 40 minutes under the protection of nitrogen to obtain shell powder; Mix tartaric acid aqueous solution, folic acid aqueous solution, D-glucuronic acid aqueous solution, D-galacturonic acid aqueous solution and shell powder evenly, and react for 13 hours to obtain a reaction solution;

[0035] (2) Mix t...

Embodiment 2

[0038] A kind of calcium tartrate preparation comprises the following components by weight percentage:

[0039]

[0040] The preparation method of above-mentioned calcium tartrate agent, comprises the following steps:

[0041] (1) Tartaric acid, folic acid, D-glucuronic acid, D-galacturonic acid are prepared into aqueous solution respectively, the concentration of tartaric acid aqueous solution, folic acid aqueous solution, D-glucuronic acid aqueous solution, D-galacturonic acid aqueous solution is 9%; the shells were soaked in 0.6% hydrochloric acid for 70 minutes, then washed with water, dried, and then calcined at 300°C for 18 minutes, 600°C for 30 minutes, and 900°C for 50 minutes under the protection of nitrogen to obtain shell powder; Mix tartaric acid aqueous solution, folic acid aqueous solution, D-glucuronic acid aqueous solution, D-galacturonic acid aqueous solution and shell powder evenly, and react for 12 hours to obtain a reaction solution;

[0042] (2) Mix th...

Embodiment 3

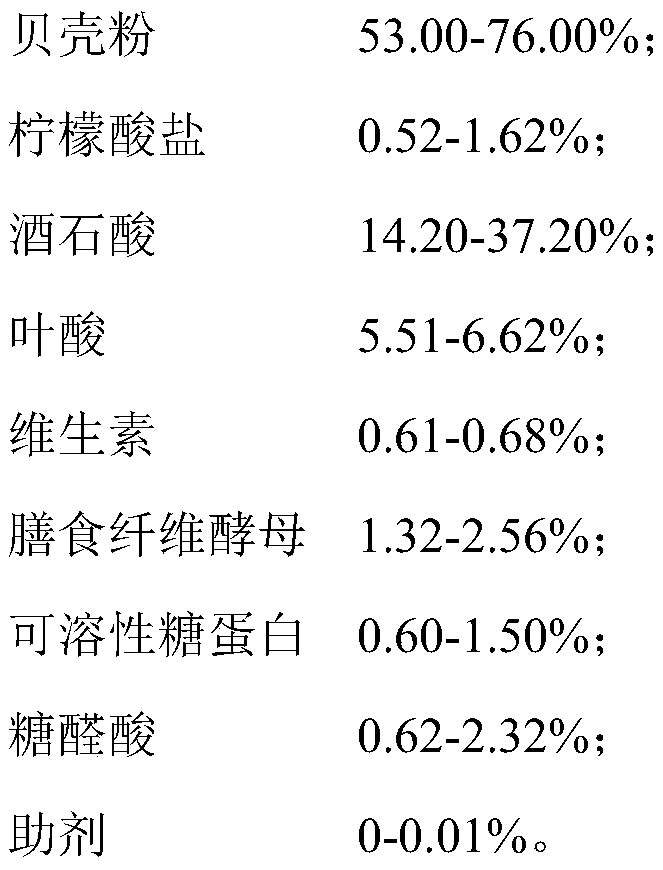

[0045] A kind of calcium tartrate preparation comprises the following components by weight percentage:

[0046]

[0047]

[0048] The preparation method of above-mentioned calcium tartrate agent, comprises the following steps:

[0049] (1) Tartaric acid, folic acid, D-glucuronic acid, D-galacturonic acid are prepared into aqueous solution respectively, the concentration of tartaric acid aqueous solution, folic acid aqueous solution, D-glucuronic acid aqueous solution, D-galacturonic acid aqueous solution is 11%; the shells were soaked in 0.8% hydrochloric acid for 50 minutes, then washed with water, dried, and then calcined at 400°C for 10 minutes, 700°C for 25 minutes, and 1000°C for 40 minutes under the protection of nitrogen to obtain shell powder; then Mix tartaric acid aqueous solution, folic acid aqueous solution, D-glucuronic acid aqueous solution, D-galacturonic acid aqueous solution and shell powder evenly, and react for 15 hours to obtain a reaction solution; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com