Method for preparing g-C3N4/CdS composite catalyst through photodeposition

A g-c3n4, optical deposition technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of difficult design and synthesis, less particle size research, etc., and achieve excellent visible light response. properties, the preparation method is simple and convenient, and the effect of excellent photolysis water hydrogen production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this example, g-C was prepared by photodeposition 3 N 4 The method steps of / CdS composite photocatalyst are as follows:

[0038] (1) Body g-C 3 N 4 preparation of

[0039]Weigh 10g of melamine and place it in a crucible, transfer it to a muffle furnace, raise the temperature to 550°C at a heating rate of 2.3°C / min, and keep it for 4h to obtain the bulk g-C 3 N 4 ;

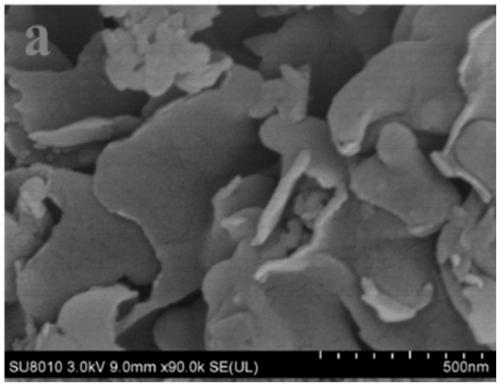

[0040] (2)g-C 3 N 4 Preparation of nanosheets

[0041] With the body g-C obtained in step (1) 3 N 4 The powder was placed in a crucible, and in a muffle furnace, the temperature was raised to 500°C at a rate of 5°C / min and kept for 2 hours to prepare g-C 3 N 4 Nanosheets;

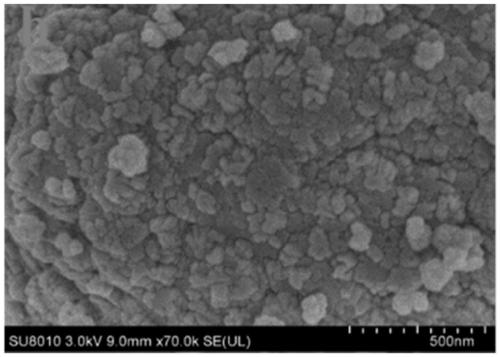

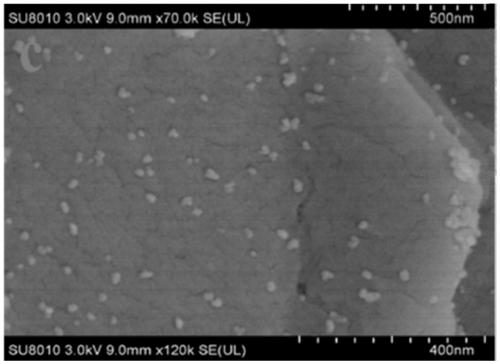

[0042] (3) g-C 3 N 4 / Synthesis of CdS

[0043] With the g-C obtained in step (2) 3 N 4 Add 200mg of nanosheets to 200ml of absolute ethanol, and disperse evenly by ultrasonic to obtain g-C 3 N 4 Mixture, followed by g-C 3 N 4 1.23g of cadmium nitrate and 64mg of precipitated sulfur were respectively added to the...

Embodiment 2

[0056] The g-C prepared in the present embodiment 1 3 N 4 / CdS composite photocatalyst CS-T, carry out X-ray powder diffraction, and g-C among the embodiment 1 simultaneously 3 N 4 X-ray diffraction with pure CdS. The obtained XRD diffraction pattern is compared, such as Figure 6 Shown, the crystal diffraction peaks of CS-4 and g-C 3 N 4 Corresponding to the crystal diffraction peak of CdS, no impurity peaks appear, indicating that g-C 3 N 4 Both form a good composite catalyst with CdS.

Embodiment 3

[0058] The g-C prepared in the present embodiment 1 3 N 4 / CdS composite photocatalyst CS-T conducts experiments on photolysis of water to produce hydrogen, and tests its photocatalytic hydrogen production performance. The specific method is as follows:

[0059] Weigh 20mg of CS-T, ultrasonically disperse it into 90ml of water, add 10ml of lactic acid as a sacrificial agent solution, put it into a photochemical reaction instrument, vacuumize for half an hour, turn on the light (300W Xe lamp wavelength > 420nm) for hydrogen production test , and regularly passed through gas chromatography (MS-5A molecular sieve, TCD, N 2 as the carrier gas) to measure the production of hydrogen gas.

[0060] Such as Figure 7 As shown in a, the amount of hydrogen produced increases significantly with the prolongation of the photodeposition preparation time, and the hydrogen production reaches the highest when the photodeposition preparation time is 4 hours. When the light time was prolonged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com