Prussian blue material and preparation method thereof

A Prussian blue and solution technology, applied in the field of Prussian blue material and its preparation, can solve problems such as unsatisfactory chemical and electrochemical stability of compounds, and achieve improved electrochemical performance, good chemical and electrochemical stability, and increased sodium content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Sodium ferrocyanide is dissolved in deionized water, stirred evenly to obtain solution I whose concentration is 0.03mol / L in terms of ferrocyanide ion; manganous chloride is dissolved in deionized water to obtain 2+ A solution with a metered concentration of 0.18mol / L, wherein the volume of the sodium ferrocyanide solution is 5 times the volume of the manganous chloride solution, and is fully stirred to obtain solution II; the sodium chloride is dissolved in deionized water to obtain a concentration of 0.3 mol / L solution III, wherein the volume of solution III is the same as that of solution I; then, under continuous stirring, add solution I and solution II to solution III at the same time, undergo co-precipitation reaction at 90°C, and then cool and wash , separated and dried to obtain the Prussian material Na x MnFe(CN) 6 .

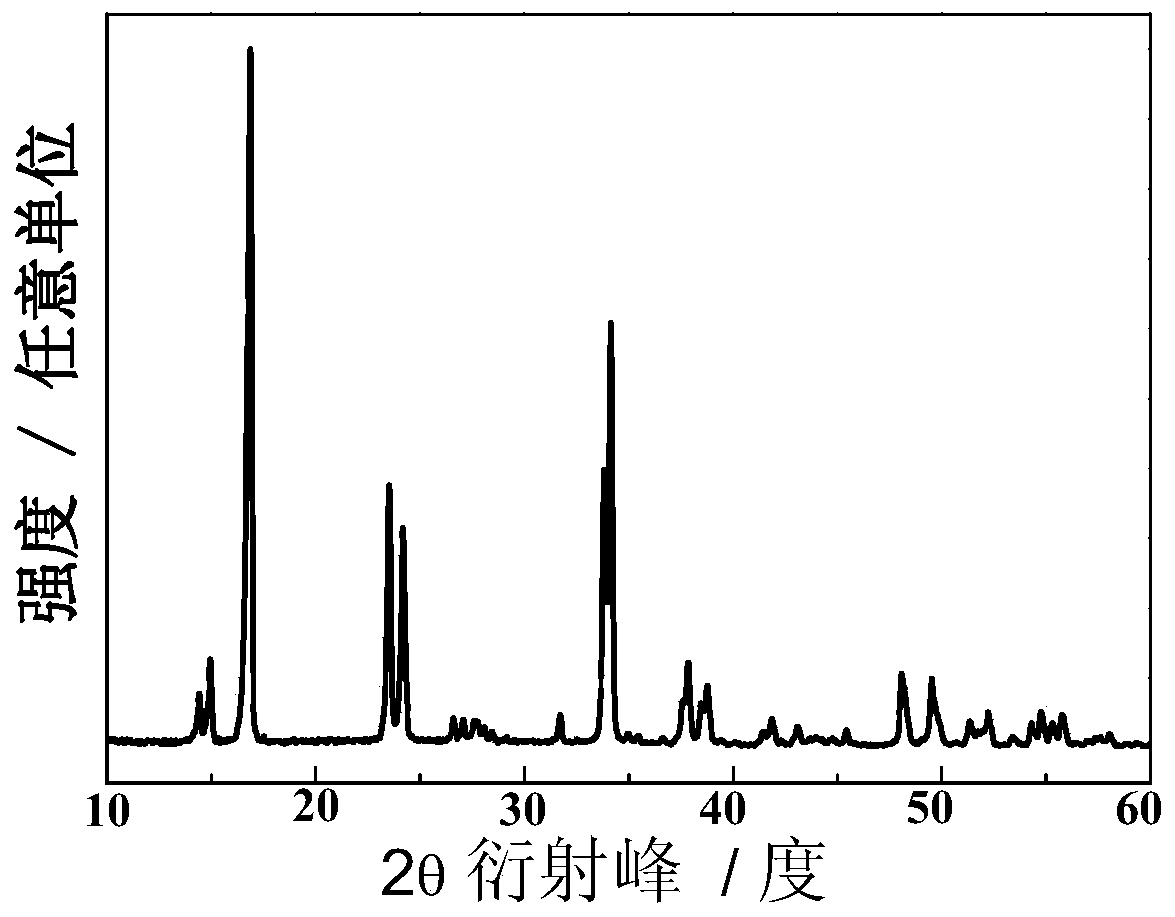

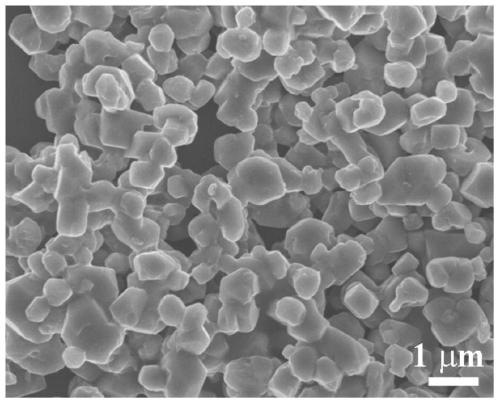

[0026] figure 1 According to XRD analysis of the Prussian material prepared for this implementation, it is a monoclinic phase. figure 2 The...

Embodiment 2

[0036] Dissolve sodium ferrocyanide in deionized water, stir evenly to obtain a concentration of 0.1 in terms of ferrocyanide ion

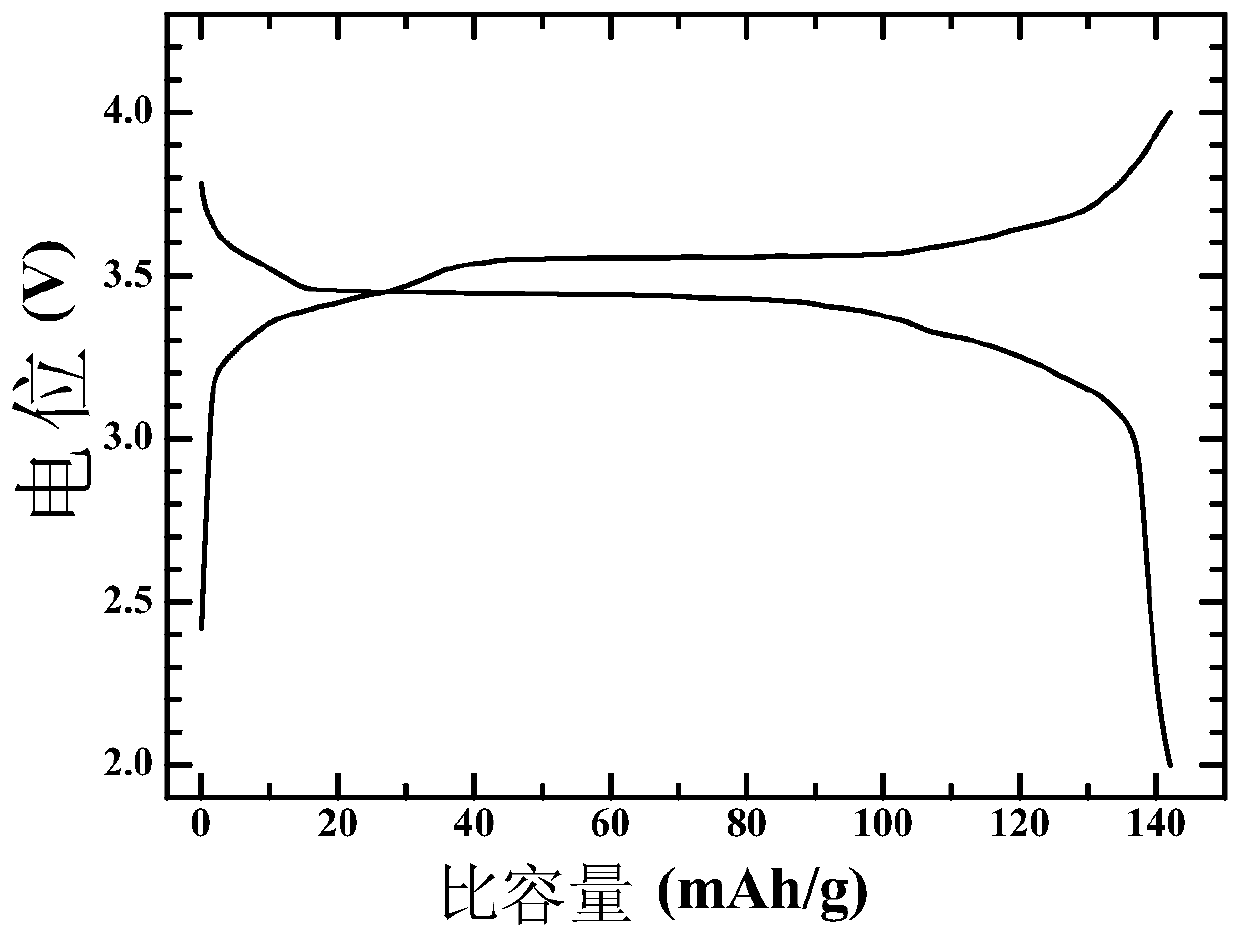

[0037] Solution I of mol / L; Dissolve manganous sulfate in deionized water to obtain Mn 2+ A solution with a metered concentration of 0.33 mol / L, wherein the volume of the sodium ferrocyanide solution is 3 times the volume of the manganese sulfate solution, and is fully stirred to obtain solution II; the sodium fluoride is dissolved in deionized water to obtain a concentration of 0.3 mol / L solution III, wherein the volume of solution III is 3 times the volume of solution I; then, under continuous stirring, add solution I and solution II to solution III at the same time, undergo co-precipitation reaction at 70 ° C, and then cool and wash , separation, and drying to obtain the Prussian material Na with a monoclinic phase of micro-nano structure x MnFe(CN) 6. The electrochemical test shows that the initial capacity of the product can reach 141mAh / ...

Embodiment 3

[0039] Sodium ferrocyanide decahydrate is dissolved in deionized water, and stirred evenly to obtain solution I whose concentration is 0.3mol / L in terms of ferrocyanide ions; manganous nitrate is dissolved in deionized water to obtain 2+ A solution with a metered concentration of 0.3 mol / L, wherein the volume of the decahydrate sodium ferrocyanide solution is the same as that of the manganous nitrate solution, and the solution II is obtained through thorough stirring; the sodium acetate is dissolved in deionized water to obtain the solution III with a concentration of 0.6 , wherein the volume of solution III is 5 times the volume of solution I; then, under continuous stirring, solution I and solution II are added to solution III at the same time, and undergo co-precipitation reaction at 50°C, and then cool, wash, separate and dry A monoclinic Prussian material Na with micro-nano structure was obtained x MnFe(CN) 6 . The electrochemical test shows that the initial capacity of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com