In-situ-synthesized fake binary complex-phase rare earth niobate ceramic and preparation method thereof

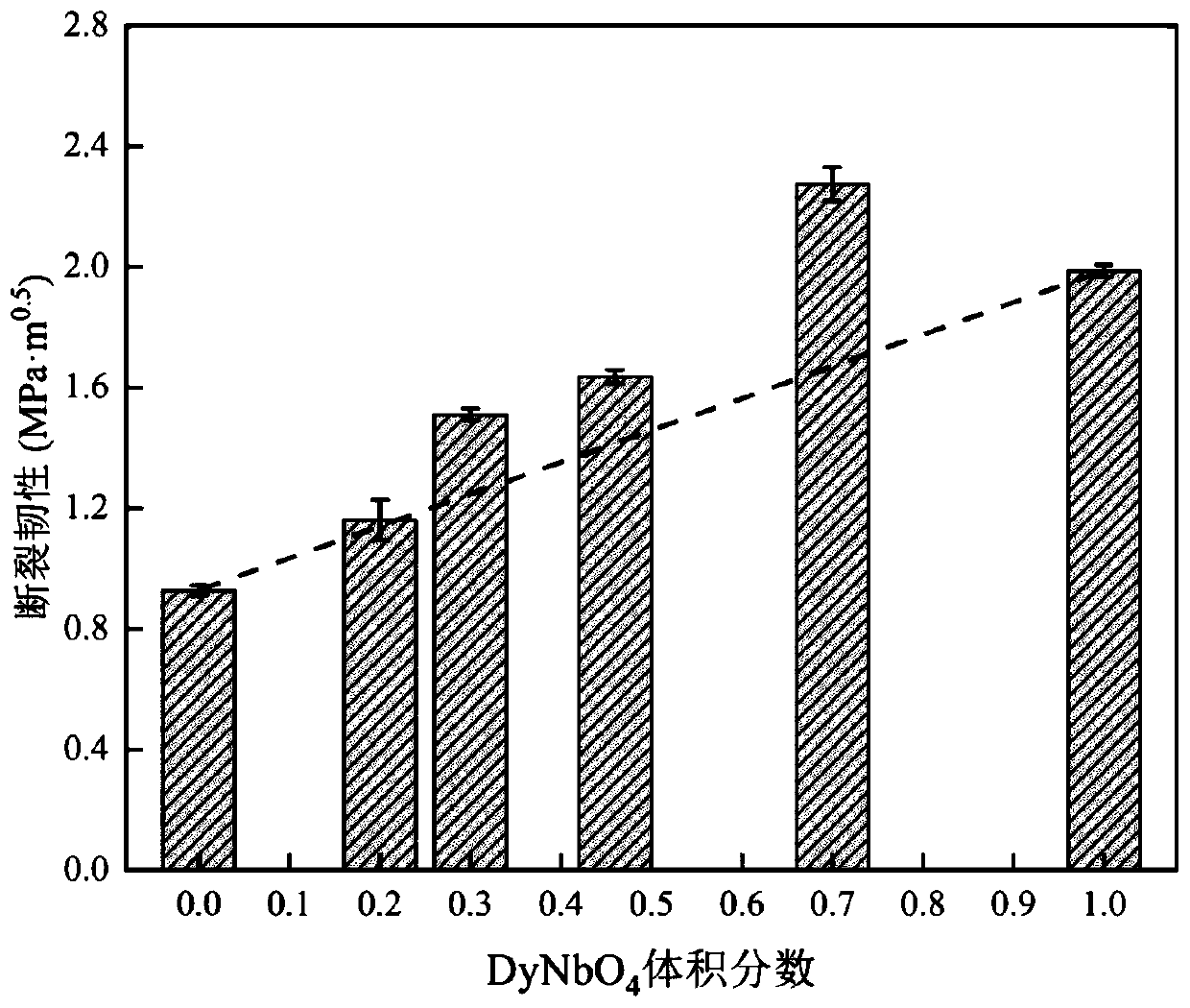

An in-situ synthesis and pseudo-binary technology, applied in the field of high-temperature materials, can solve the problems of low fracture toughness and cannot be directly applied, and achieve the effects of improved fracture toughness, low preparation cost, and good high-temperature thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

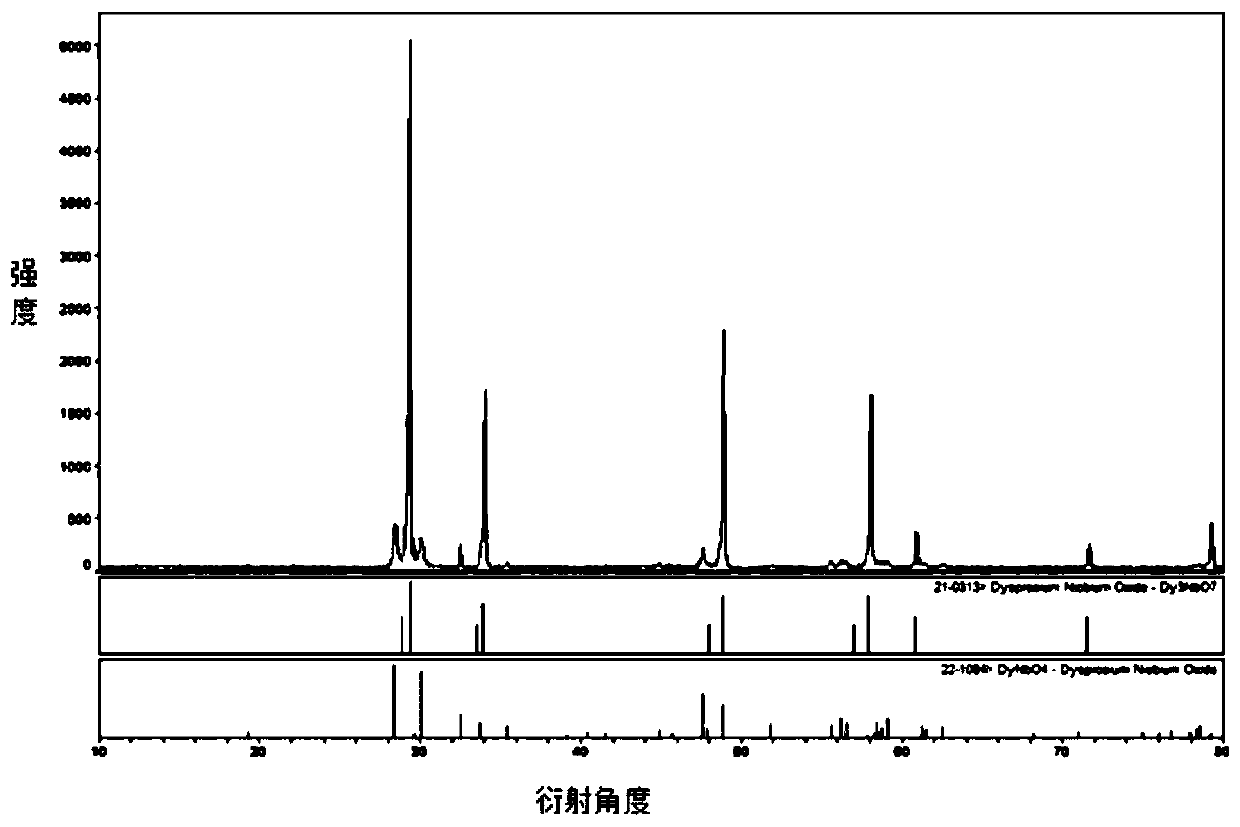

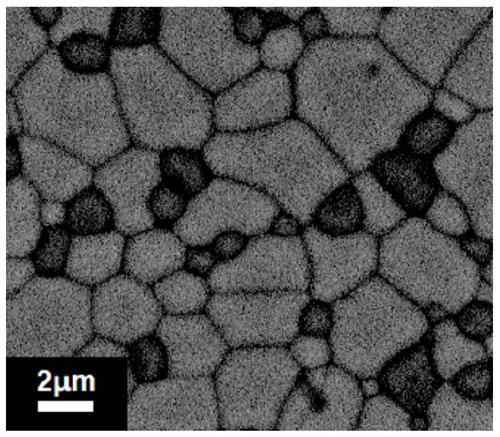

[0031] A kind of pseudo-binary complex-phase yttrium niobate (Y 3 NbO 7 -YNbO 4 ) high-temperature ceramic material and preparation method thereof, specifically comprising the following steps:

[0032] (1) Weigh 6.1036g of yttrium oxide and 3.4475g of niobium oxide, mix them in absolute ethanol, and place them in a planetary ball mill for ball milling (the speed of the ball mill is 250r / min, and the ball milling time is 240min), and the milled solution Pre-fired at 1250° C. for 10 hours after rotary evaporation drying.

[0033] (2) After pre-sintering, grind the mixed powder evenly, mix and grind the powder with absolute ethanol as a solvent, and place it in a planetary ball mill for ball milling (the speed of the ball mill is 250r / min, and the ball milling time is 600min); ball mill the powder After rotary evaporation and drying, pass through a 200-mesh sieve to obtain a fine powder; then use hydraulic pressure to form (holding pressure is 5 MPa, holding time is 5min), and...

Embodiment 2

[0035] A new pseudo-binary complex phase lanthanum niobate (La 3 NbO 7 -LaNbO 4 ) high-temperature ceramic material and preparation method thereof, specifically comprising the following steps:

[0036] (1) Weigh 8.8002g of lanthanum oxide and 3.4526g of niobium oxide, mix them in absolute ethanol, place them in a planetary ball mill for ball milling (the speed of the ball mill is 250r / min, and the ball milling time is 240min), and the milled solution Pre-fired at 1250° C. for 10 hours after rotary evaporation drying.

[0037](2) After pre-sintering, grind the mixed powder evenly, mix and grind the powder with absolute ethanol as a solvent, and place it in a planetary ball mill for ball milling (the speed of the ball mill is 250r / min, and the ball milling time is 600min); ball mill the powder After rotary evaporation and drying, pass through a 200-mesh sieve to obtain a fine powder; then use hydraulic pressure to form (holding pressure is 5 MPa, holding time is 5min), and th...

Embodiment 3

[0039] A new type of pseudo-binary complex phase cerium niobate (Ce 3 NbO 7 -CeNbO 4 ) high-temperature ceramic material and preparation method thereof, specifically comprising the following steps:

[0040] (1) Weigh 8.8502g of cerium oxide and 3.4478g of niobium oxide, mix them in absolute ethanol, place them in a planetary ball mill for ball milling (the speed of the ball mill is 250r / min, and the ball milling time is 240min), and the milled solution Pre-fired at 1250° C. for 10 hours after rotary evaporation drying.

[0041] (2) After pre-sintering, grind the mixed powder evenly, mix and grind the powder with absolute ethanol as a solvent, and place it in a planetary ball mill for ball milling (the speed of the ball mill is 250r / min, and the ball milling time is 600min); ball mill the powder After rotary evaporation and drying, pass through a 200-mesh sieve to obtain a fine powder; then use hydraulic pressure to form (holding pressure is 5 MPa, holding time is 5min), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com