Method for preparing p-tolualdehyde by efficiently catalyzing p-xylene by polyoxometallate

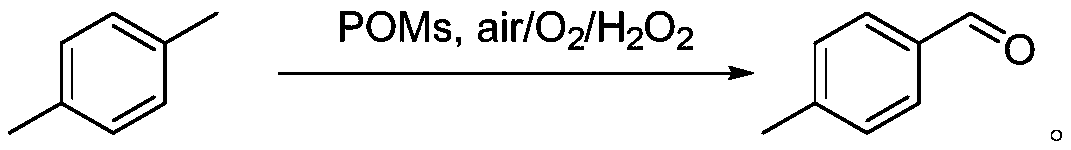

A technology of polyoxometalates and p-tolualdehyde, applied in the field of catalytic oxidation of p-xylene to prepare p-tolualdehyde, Anderson type polyoxometalates, can solve the problems of no green, environmental protection, etc., and achieve production Low cost, no three wastes, and high atomic economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

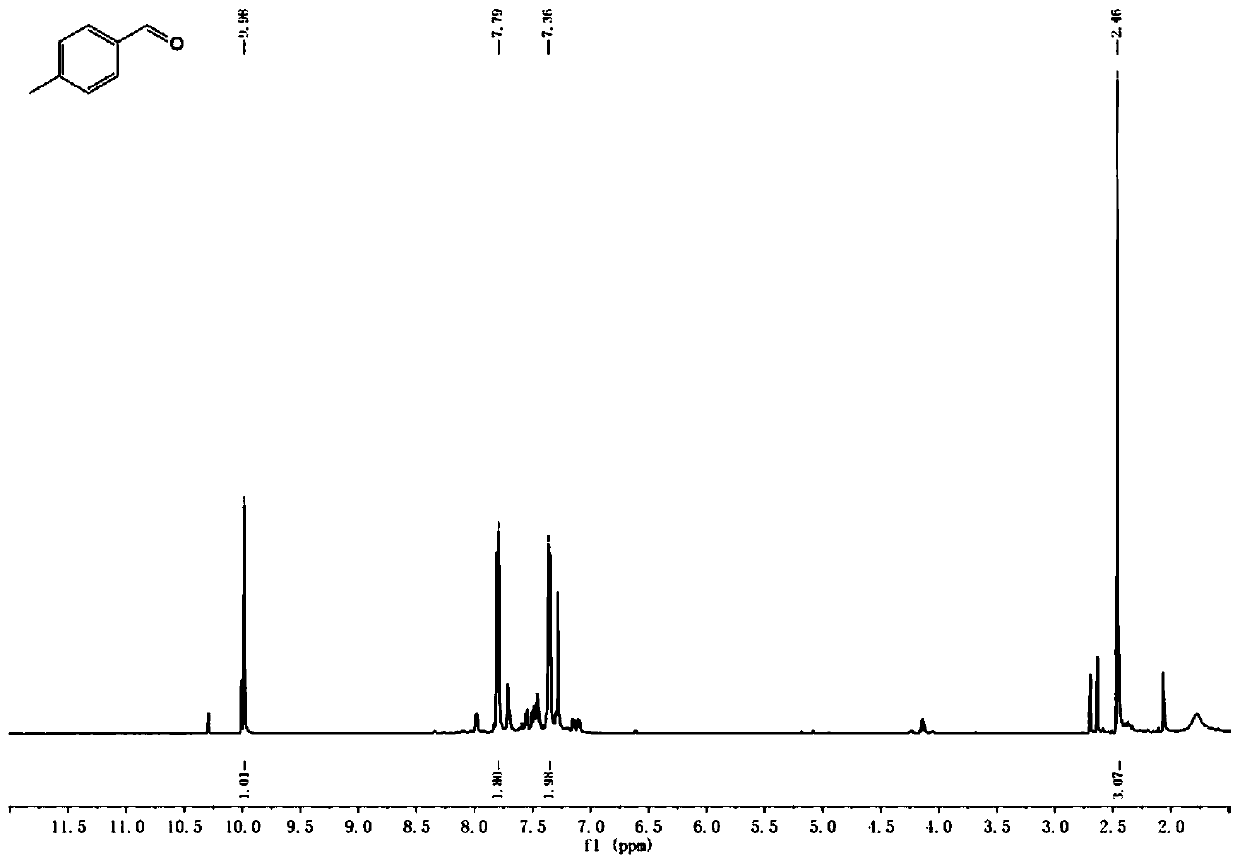

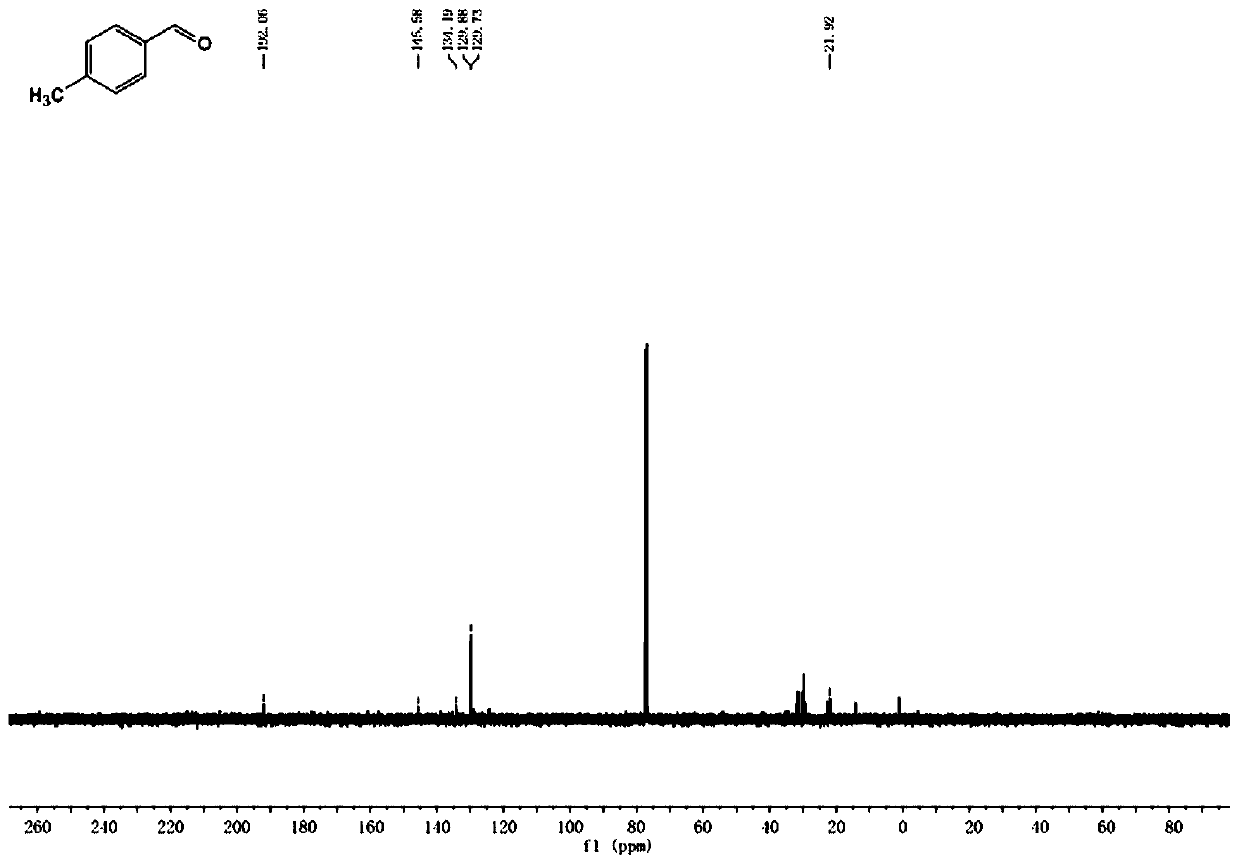

[0026] 318.5 g of p-xylene, 0.1-5.0 mol% of Fe as the Anderson type polyoxometalate of the central metal, 2.0-6.0 equiv of hydrogen peroxide, and 2.0-6.0 L of solvent acetonitrile are dropped into the dry reaction tube, The reaction tube was covered with a balloon, and the reaction temperature was controlled at 50-80°C. After 24 hours of heat preservation, the reaction was stopped, cooled to room temperature, and the sample was prepared for GC-MS detection. The GC-MS result showed that the conversion rate of the reaction substrate was 95%. Carry out NMR test after separation and purification, prove that it is p-methylbenzaldehyde by the obtained hydrogen spectrum, carbon spectrum data, such as Figure 1-2 mentioned.

Embodiment 2

[0028] Put 318.5 g of p-xylene, 0.1-5.0 mol% of Al as the center metal Anderson type polyoxometalate, 2.0-6.0 equiv of hydrogen peroxide, and 2.0-6.0 L of solvent acetonitrile into the dry reaction tube, The reaction tube was covered with a balloon, and the reaction temperature was controlled at 50-80°C. After 24 hours of insulated reaction, the reaction was stopped, cooled to room temperature, and the sample was prepared for GC-MS detection. The GC-MS result showed that the conversion rate of the reaction substrate was 93%. After separation and purification, the NMR test was carried out, and it was proved to be p-tolualdehyde by the obtained hydrogen spectrum and carbon spectrum data.

Embodiment 3

[0030] Put 318.5 g of p-xylene, 0.1-5.0 mol% of Cr as the center metal Anderson type polyoxometalate, 2.0-6.0 equiv of hydrogen peroxide, and 2.0-6.0 L of solvent acetonitrile into the dry reaction tube, The reaction tube was covered with a balloon, and the reaction temperature was controlled at 50-80°C. After 24 hours of heat preservation, the reaction was stopped, cooled to room temperature, and the sample was prepared for GC-MS detection. The GC-MS result showed that the conversion rate of the reaction substrate was 97%. After separation and purification, the NMR test was carried out, and it was proved to be p-tolualdehyde by the obtained hydrogen spectrum and carbon spectrum data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com