Method for preparing high-entropy alloy type electrocatalytic oxygen evolution reaction catalyst through high-energy ball milling

A technology of high-entropy alloy and oxygen evolution reaction, which is applied in the direction of electrodes, electrolytic components, electrolysis process, etc., can solve the problems of high cost and complex preparation method of electrocatalytic oxygen evolution reaction catalyst, and achieve low cost, excellent catalytic activity, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

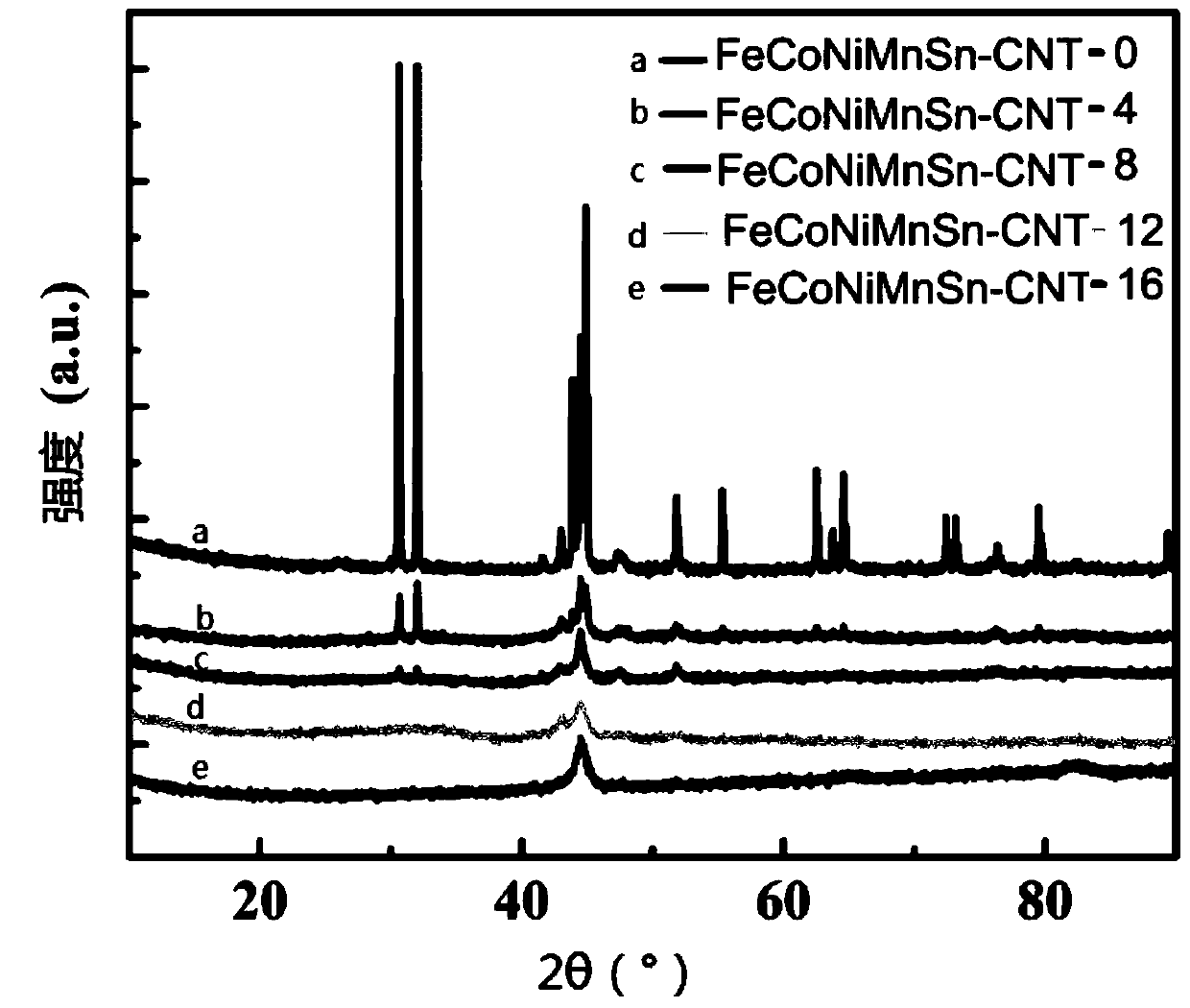

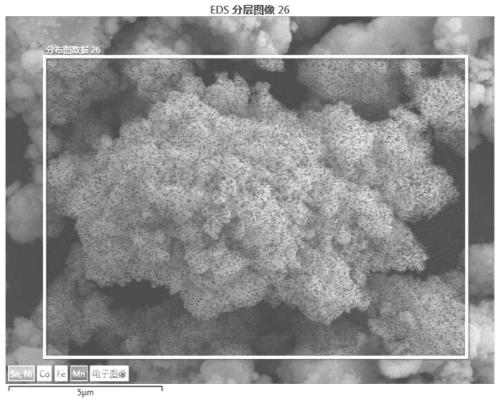

[0018] Specific Embodiment 1: The method for preparing a high-entropy alloy type electrocatalytic oxygen evolution reaction catalyst by high-energy ball milling in this embodiment is carried out according to the following steps:

[0019] 1. Weigh the main transition metal powder, auxiliary transition metal powder and carbon nanotubes and mix them uniformly to obtain a mixed powder, wherein the main transition metal powder is a mixed powder of Fe, Co, Ni and Mn, wherein Fe, Co, Ni and Mn The molar ratio is 1: (0.9~1.1): (0.9~1.1): (0.9~1.1); the auxiliary transition metal powder is Cr powder or Sn powder; the molar ratio of Fe powder and auxiliary transition metal powder is 1: (0.9~ 1.1); the ratio of the total mass of the main transition metal powder and the auxiliary transition metal powder to the mass of the carbon nanotube is (8-9): 1;

[0020] 2. Add the mixture to the high-energy ball mill, and perform ball milling at a speed of 600-1000 rpm, and pause for 10-15 minutes e...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that in step 2, the grinding balls made of zirconia are used as the ball milling medium during ball milling. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 2, the ball-to-material ratio during ball milling is (9-10):1. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com