Lithium iron phosphate modification method

A lithium iron phosphate modification technology, which is applied in the field of lithium iron phosphate modification and lithium iron phosphate modification, can solve the problems of low specific capacity, poor second electrical conductivity, and poor low temperature performance of the third lithium iron phosphate battery. , to achieve the effect of improving conductivity, improving conductivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for modifying lithium iron phosphate, using a metal oxide and carbon mixed coating method to modify lithium iron phosphate, according to the following steps:

[0020] Using 6g of lithium iron phosphate, 1g of transition metal oxysalt cobalt acetate and 3g of carbon source glucose as raw materials, put them in a ball mill jar, add a certain amount of ethanol, and mill in a ball mill for 4 hours;

[0021] The ball-milled sample was fully dried in a vacuum oven, and then heated to 600°C in a tube furnace under an argon atmosphere at a heating rate of 5°C / min and kept for 2 hours to obtain metal oxides and Carbon mixed coated lithium iron phosphate.

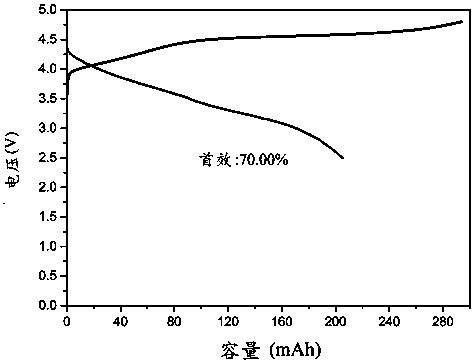

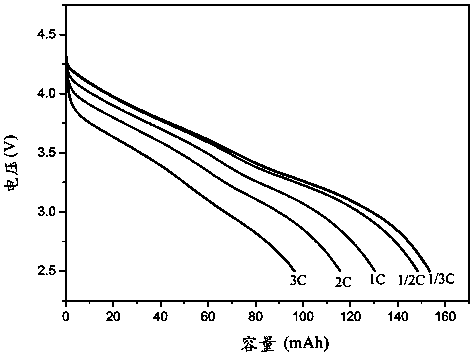

[0022] The performance of the modified lithium iron phosphate see figure 1 The first-efficiency performance diagram and figure 2 It is the discharge rate diagram of the metal oxide and carbon mixed-coated lithium iron phosphate material obtained in Example 1.

Embodiment 2

[0024] A method for lithium iron phosphate modification, according to the following steps:

[0025] Using 7g of lithium iron phosphate, 1g of transition metal oxo-salt nickel acetate and 2g of carbon source glucose as raw materials, put them in a ball mill jar, add a certain amount of ethanol, and mill in a ball mill for 4 hours;

[0026] The ball-milled sample was fully dried in a vacuum oven, and then heated to 600°C in a tube furnace under an argon atmosphere at a heating rate of 5°C / min and kept for 2 hours to obtain metal oxides and Carbon mixed coated lithium iron phosphate.

Embodiment 3

[0028] A method for lithium iron phosphate modification, according to the following steps:

[0029] Using 7g of lithium iron phosphate, 2g of transition metal oxo acid manganese acetate and 1g of carbon source sucrose as raw materials, put them in a ball mill jar, add a certain amount of ethanol, and mill in a ball mill for 4 hours;

[0030] The ball-milled sample was fully dried in a vacuum oven, and then heated to 600°C in a tube furnace under an argon atmosphere at a heating rate of 5°C / min and kept for 2 hours to obtain metal oxides and Carbon mixed coated lithium iron phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com