Method for catalytic thermal decomposition to remove zinc-cyanide complex

A complex and thermal decomposition technology, applied in the chemical industry, can solve the problems of lack of economical, effective and environmentally friendly treatment methods, and achieve the effects of less equipment investment, no secondary pollution, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

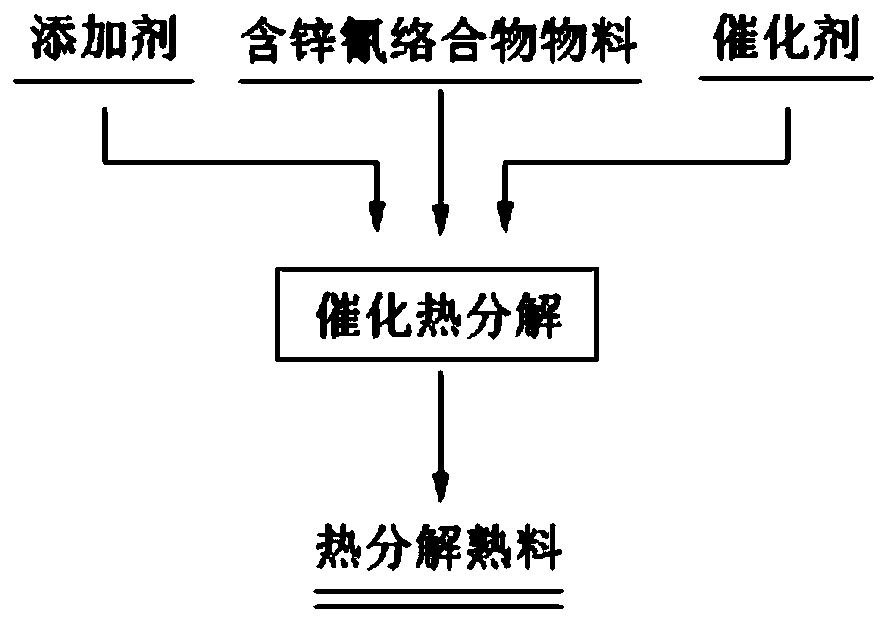

[0032] A method for catalytic thermal decomposition to remove zinc cyanide complex, comprising the steps of:

[0033] (1) Using zinc cyanide solid reagent waste as raw material, the mass ratio of zinc cyanide in the waste is 90%, adding copper oxide and iron oxide mixture in the raw material, the mass ratio is 2: 1, the mixture and the raw material The zinc-cyanide complex contained is calculated as 1:1 by mass ratio, and mixed evenly to make a mixed raw material;

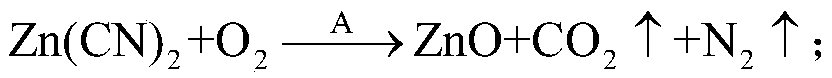

[0034] (2) Put the mixed raw materials into a roasting furnace with an air atmosphere, heat up to 400°C at a heating rate of 25°C / min for thermal decomposition, and when the temperature reaches 400°C, keep warm for 15 minutes to remove the zinc-cyanide complex to obtain thermal decomposition clinker; the chemical reaction equations involved in the thermal decomposition process include:

[0035]

[0036] (3) directly stockpiling the obtained thermal decomposition clinker.

[0037] After testing, it was found th...

Embodiment 2

[0039] A method for catalytic thermal decomposition to remove zinc cyanide complex, comprising the steps of:

[0040] (1) With zinc cyanide solid reagent waste as raw material, zinc cyanide mass ratio is 90% in this waste material, copper oxide is added in raw material, the zinc cyanide complex contained in described copper oxide and raw material is by mass ratio Calculated as 1:2, mixed evenly to make mixed raw materials;

[0041] (2) Put the mixed raw materials into a roasting furnace with an air atmosphere, heat up to 350°C at a heating rate of 5°C / min for thermal decomposition, and when the temperature reaches 350°C, keep warm for 90 minutes to remove the zinc-cyanide complex to obtain thermal decomposition clinker; the chemical reaction equations involved in the thermal decomposition process include:

[0042]

[0043] (3) directly stockpiling the obtained thermal decomposition clinker.

[0044]After testing, it was found that the initial zinc cyanide content in the m...

Embodiment 3

[0046] A method for catalytic thermal decomposition to remove zinc cyanide complex, comprising the steps of:

[0047] (1) Sodium zinc cyanate (Na 2 Zn(CN) 4 ) Reagent waste as raw material, sodium zinc cyanate mass ratio is 90% in this waste material, adds iron oxide in raw material, and iron oxide is specifically iron oxide, ferric oxide and ferrous oxide and is 1 by mass ratio: The mixture formed by mixing 1:1, the iron oxide and the zinc-cyanide complex contained in the raw material are calculated at a mass ratio of 7:10, and mixed uniformly to make a mixed raw material;

[0048] (2) Put the mixed raw materials into a roasting furnace with an air atmosphere, heat up to 470°C at a heating rate of 30°C / min for thermal decomposition, and when the temperature reaches 470°C, complete the thermal decomposition and remove the zinc-cyanide complex to obtain thermal decomposition clinker; the chemical reaction equations involved in the thermal decomposition process include:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com