Method and device for separating heat energy and cold energy by vacuum sublimation and evaporation

A separation and vacuum technology, applied in separation methods, sublimation, chemical instruments and methods, etc., can solve the problems of tight supply of natural gas resources, high electricity costs, and difficulty in promotion, and achieve the separation and use of cold and hot energy. The link of transmission and the effect of improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

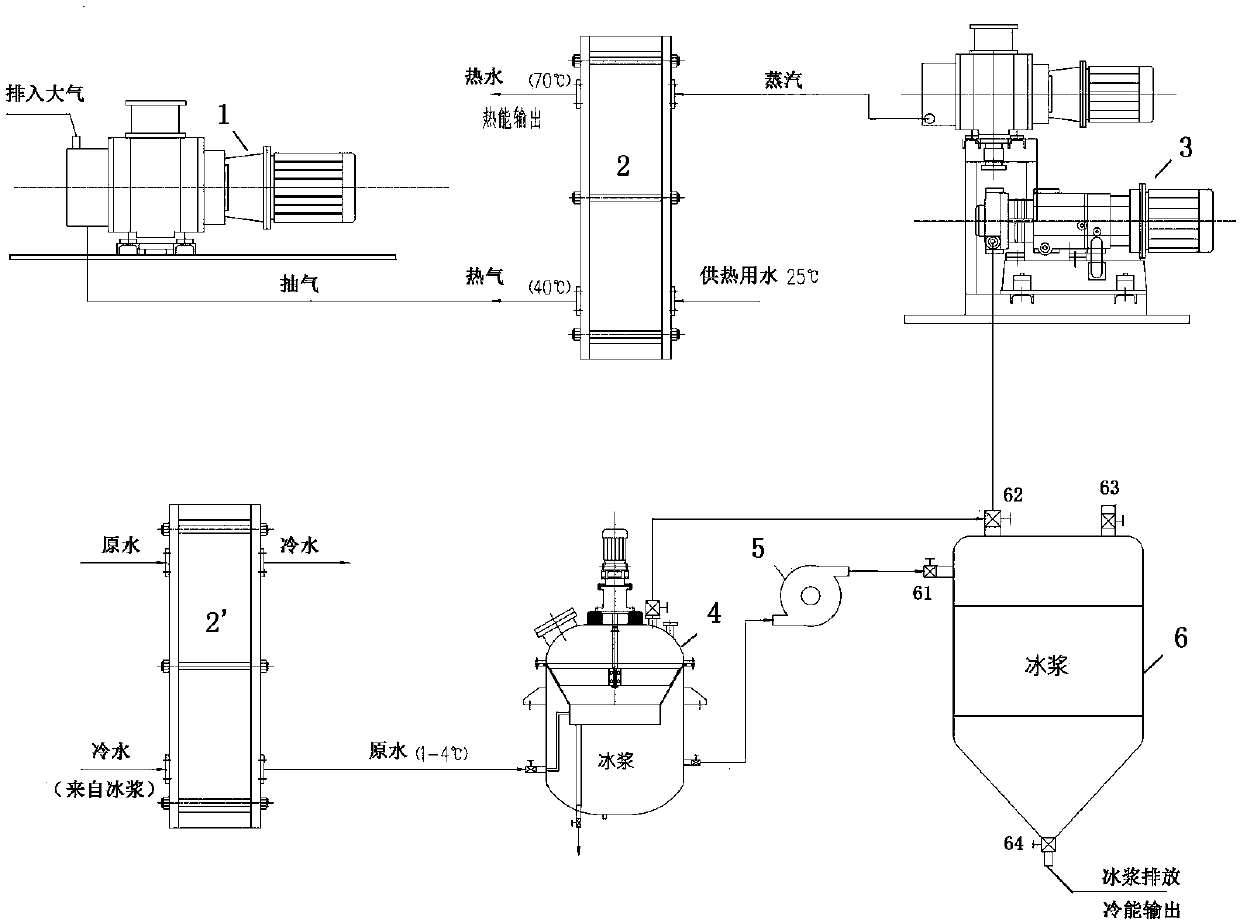

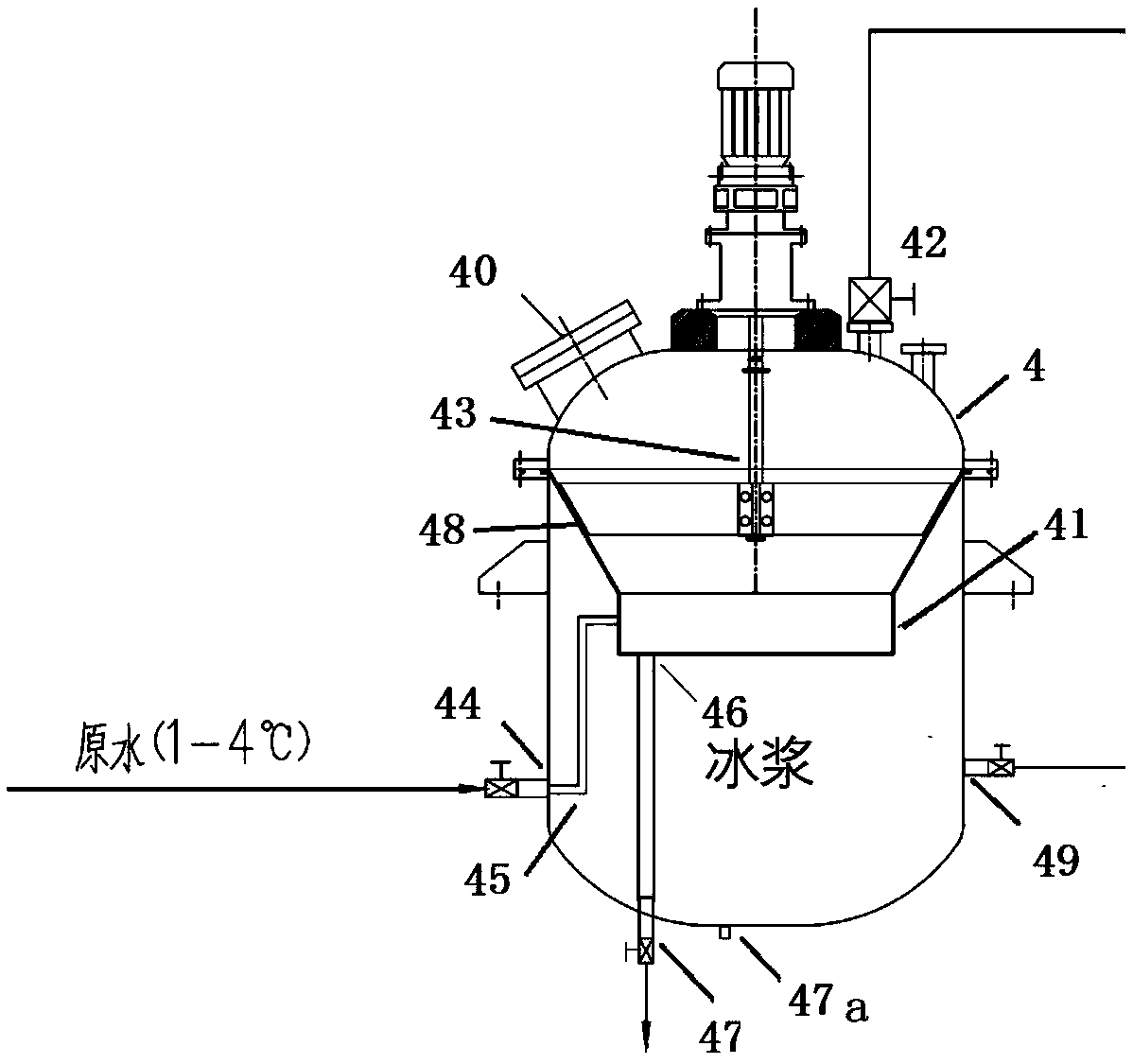

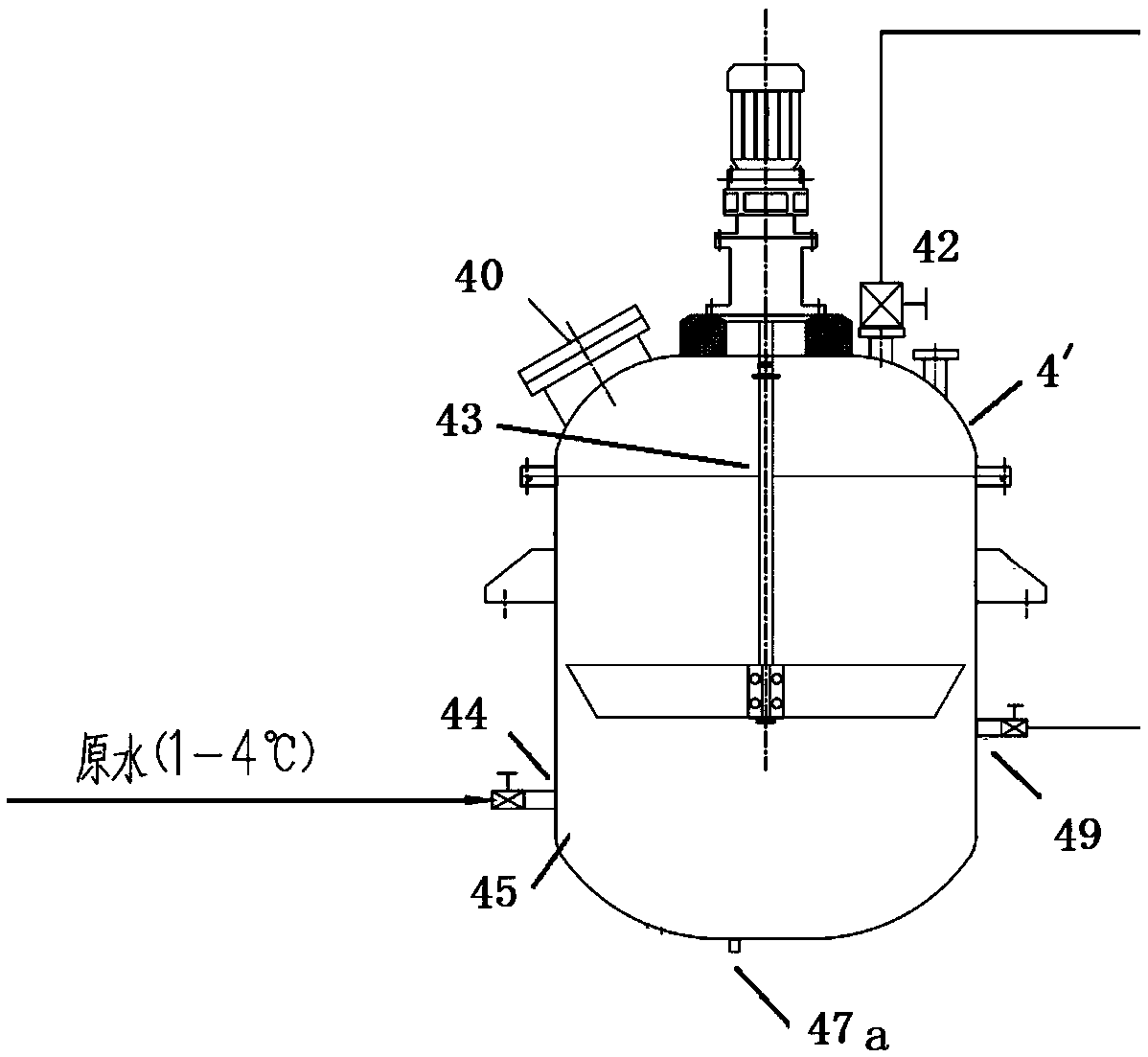

[0045] As an example of the vacuum sublimation evaporation cold heat energy separation method provided by the present invention, as figure 1 and Figure 1a A device is shown.

[0046]A sealed container of this device is called crystallizer 4, forms an artificial environment in the crystallizer 4, is provided with liquid inlet 44, gas outlet 42 and solid-liquid mixture outlet 49 in the crystallizer 4, connects a vacuum on this gas outlet 42 The sublimation evaporation unit 2 is also provided with an agitator 43 in the crystallizer 4 . The separation method is:

[0047] Step 1: Establish a vacuum artificial environment in the crystallizer 4, connect the gas outlet 42 on the crystallizer 4 through a vacuum sublimation evaporation unit, that is, a vacuum pump unit 3, and vacuumize the crystallizer 4, so that the pressure in the crystallizer 4 Reduce to 600-100Pa, such as 128Pa, in crystallizer 4, input raw water through liquid inlet 44. Under the working condition of the vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com