Alumina/calcium silicate graded composite film and preparation method and application thereof

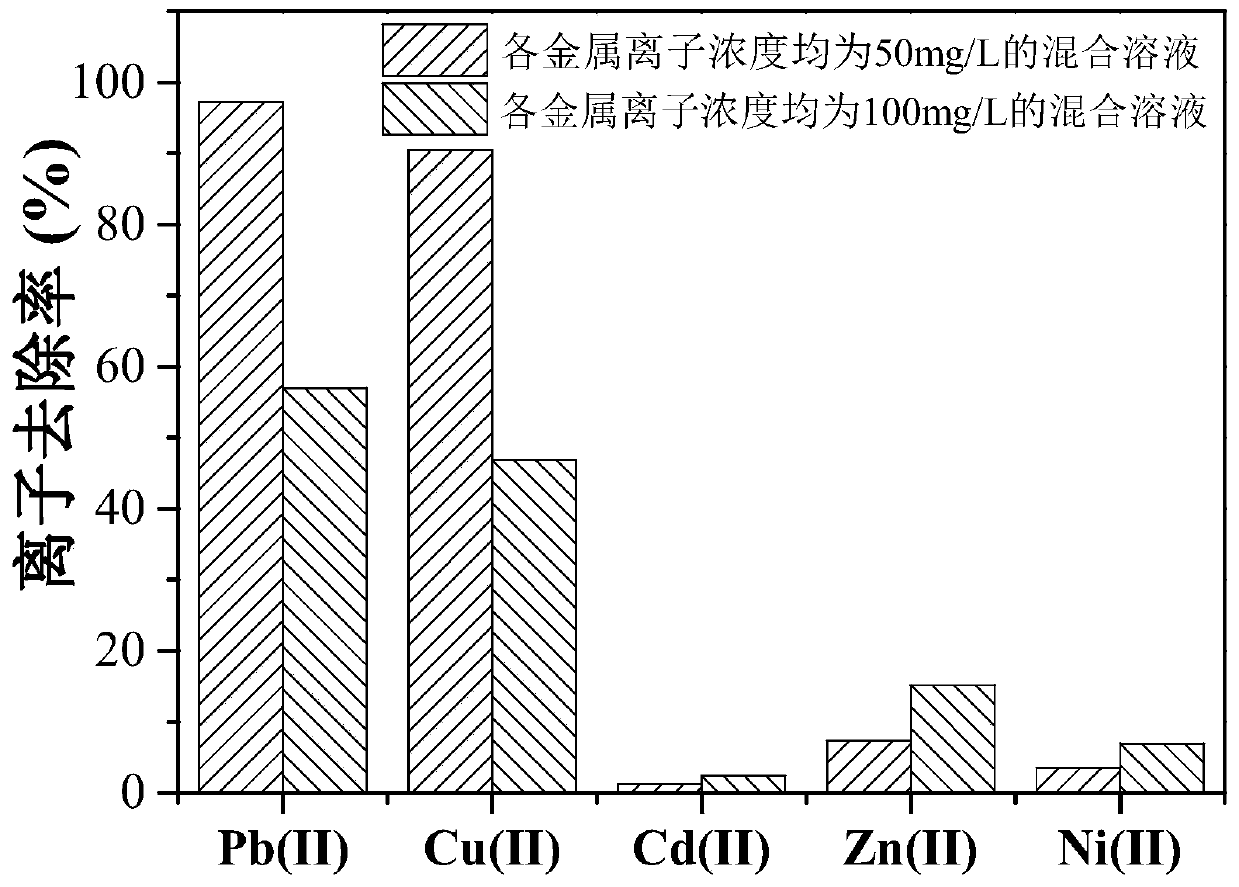

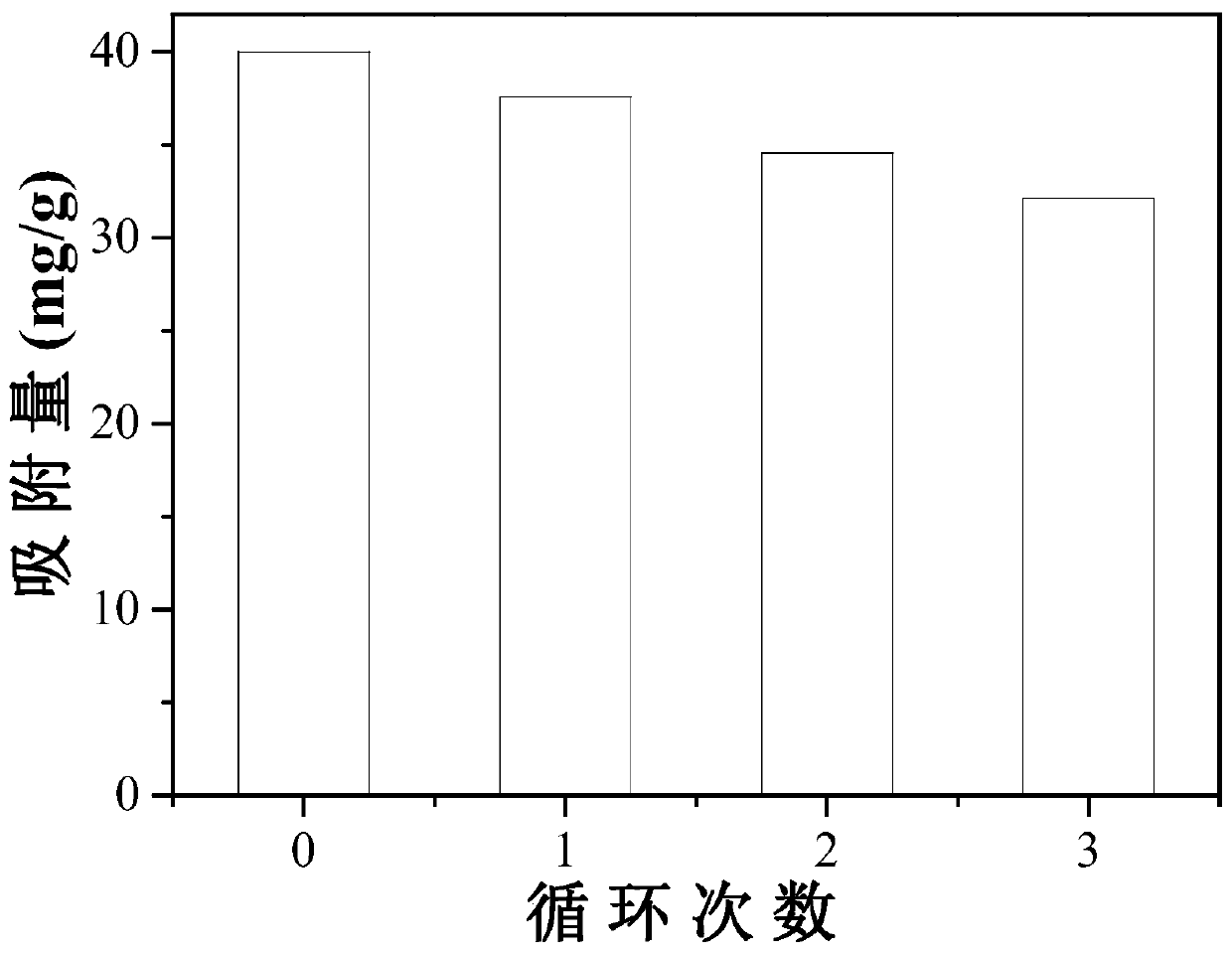

A technology of composite film and calcium silicate, which is applied in chemical instruments and methods, alkali metal oxides/hydroxides, silicon compounds, etc., can solve the problems of poor binding ability between surface hydroxyl groups and metal cations, and achieve excellent cycle performance, The effect of saving separation cost and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 2.4g HMT and 0.18g CaCl were mixed at room temperature 2 Disperse in 50mL deionized water, the solution is clear and transparent, pour it into a 100mL hydrothermal kettle, place a piece of γ-Al 2 o 3 After the film was heated in water at 140°C for 6 hours, the film was taken out after the water heating was completed, the surface of the film was washed repeatedly with ethanol and water and then dried in an oven at 50°C for 1 hour. Place the dried film in a 100mL hydrothermal kettle, then add 50mL containing 0.05g Na 2 SiO 3 9H 2 O aqueous solution and heated in water at 160°C for 12h, took out the film, rinsed the film surface repeatedly with ethanol and water, and dried it in an oven at 50°C for 1h to obtain γ-Al 2 o 3 @CS composite film.

[0044] XRD test and corresponding data processing and result analysis show that γ-Al appears in both 2θ=46° and 66° 2 o 3 The characteristic diffraction peaks of γ-Al 2 o 3 @CS CaSiO also appeared at 2θ=28° and 39° 3 chara...

Embodiment 2

[0047] 4g HMT and 0.3g CaCl at room temperature 2 Disperse in 50mL deionized water, the solution is clear and transparent, pour it into a 100mL hydrothermal kettle, place a piece of γ-Al 2 o 3 After the film was heated in water at 160°C for 6 hours, the film was taken out after the water heating was completed, the surface of the film was washed repeatedly with ethanol and water and then dried in an oven at 50°C for 1 hour. Place the dried film in a 100mL hydrothermal kettle, then add 50mL containing 0.08g Na 2 SiO 3 9H 2 O aqueous solution and heated in water at 140°C for 12h, took out the film, rinsed the film surface repeatedly with ethanol and water, and dried it in an oven at 50°C for 1h to obtain γ-Al 2 o 3 @CS composite film.

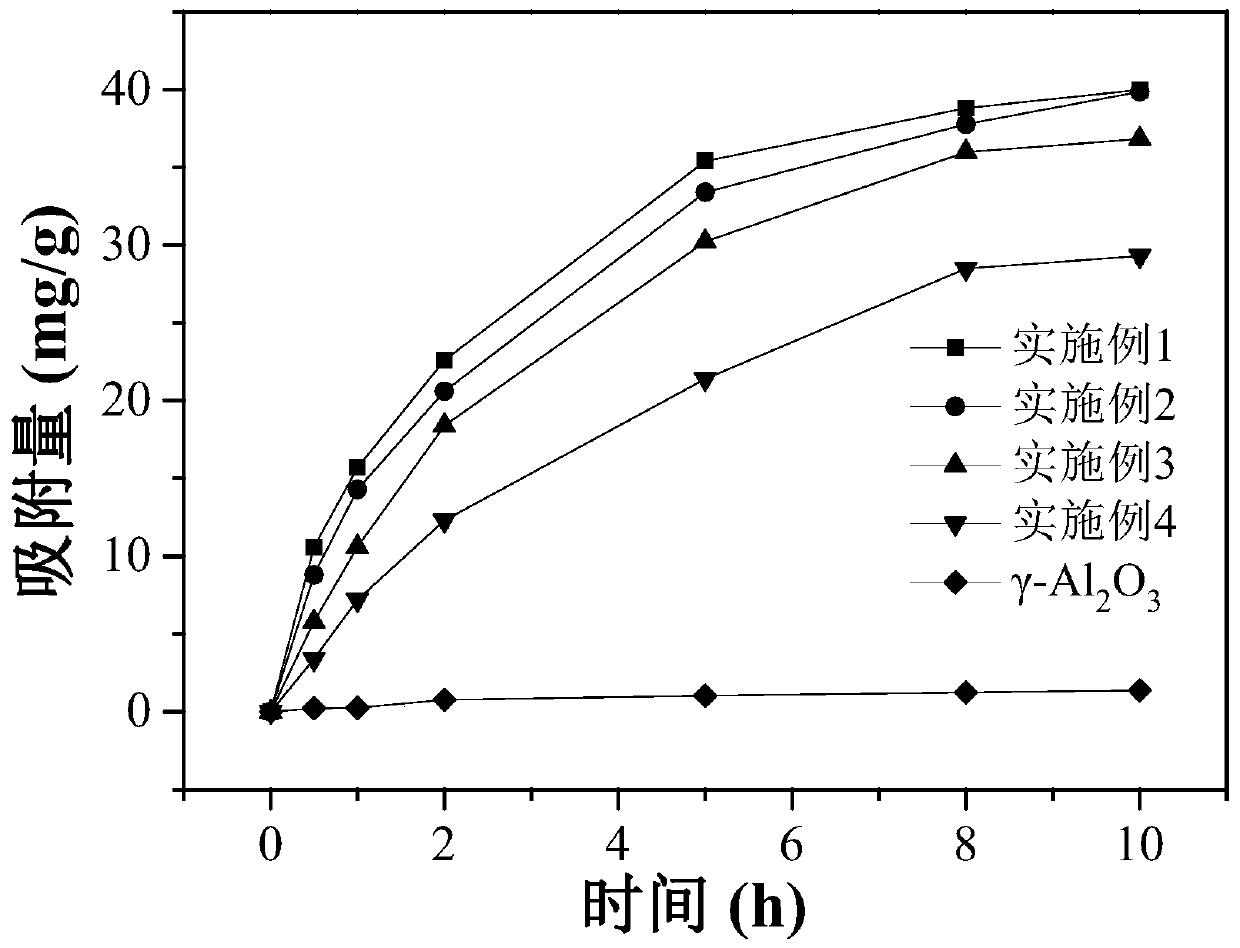

[0048] When adsorbing 50ml, 80mg / L of Pb(II) solution, adjust the pH to 6 with a sodium hydroxide solution with a concentration of 0.1mol / L, and then add 0.1g of γ-Al 2 o 3 @CS thin film sample, set the parameters of the constant temperatu...

Embodiment 3

[0050] 3g HMT and 0.15g CaCl at room temperature 2 Disperse in 50mL deionized water, the solution is clear and transparent, pour it into a 100mL hydrothermal kettle, place a piece of γ-Al 2 o 3 After the film was heated in water at 150°C for 6 hours, the film was taken out after the water heating was completed, the surface of the film was washed repeatedly with ethanol and water and then dried in an oven at 50°C for 1 hour. Place the dried film in a 100mL hydrothermal kettle, then add 50mL containing 0.07g Na 2 SiO 3 9H 2 O aqueous solution was heated at 150°C for 12 hours, the film was taken out, rinsed with ethanol and water repeatedly, and then dried in an oven at 50°C for 1 hour to obtain γ-Al 2 o 3 @CS composite film.

[0051] When adsorbing 50ml, 80mg / L of Pb(II) solution, adjust the pH to 6 with a sodium hydroxide solution with a concentration of 0.1mol / L, and then add 0.1g of γ-Al 2 o 3 @CS thin film sample, set the parameters of the constant temperature oscill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com