Cesium ion adsorbent as well as preparation method and application thereof

A cesium ion and adsorbent technology, applied in the field of cesium ion adsorbent and its preparation, can solve the problems of easy solification, high selectivity and high cost, and achieve high adsorption capacity, excellent desorption and cycle performance, and high selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

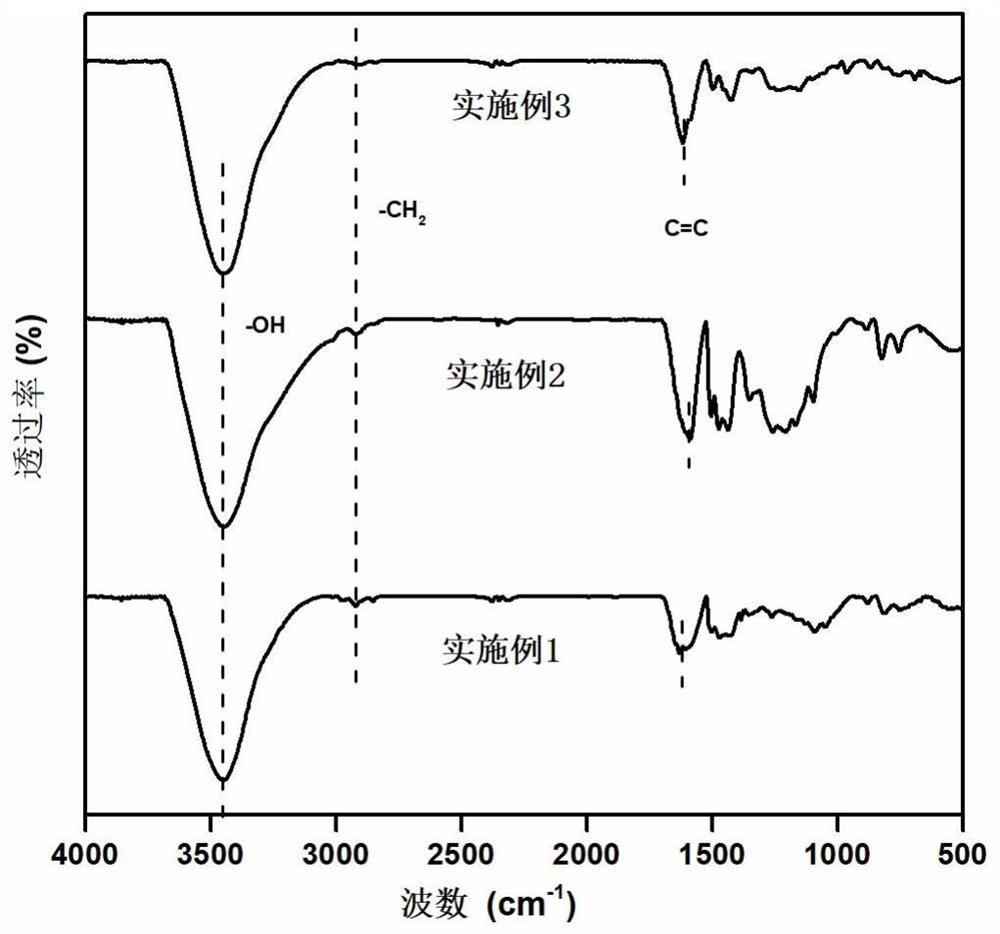

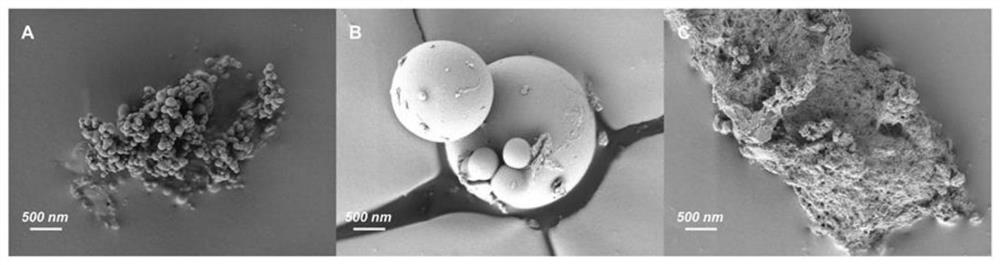

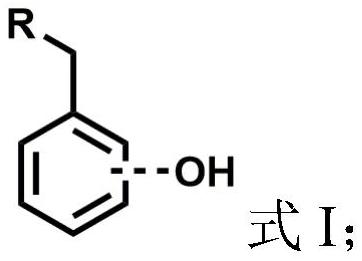

[0074] This embodiment provides a cesium ion adsorbent, the raw material of the cesium ion adsorbent is p-hydroxybenzyl alcohol, and the pore diameter of the cesium ion adsorbent is 2.38 nm.

[0075] The present embodiment provides a preparation method of the cesium ion adsorbent, and the specific steps include:

[0076] Under a nitrogen atmosphere, p-hydroxybenzyl alcohol (2.48g, 0.02mol) was dissolved in 50mL of dichloroethane, anhydrous ferric chloride (3.25g, 0.02mol) was added to react at 45°C for 5h, and then The reaction temperature was raised to 80°C for 19 hours; after the reaction, cooled to room temperature and suction filtered to obtain an insoluble black solid; the solid was sequentially used in 0.05mol L -1 Washed with hydrochloric acid solution for 2h, washed with ultrapure water until the filtrate was neutral, washed with methanol until the filtrate became clear, then the separated solid product was further extracted with methanol Soxhlet for 24h to remove the ...

Embodiment 2

[0078] This embodiment provides a cesium ion adsorbent, the raw material of the cesium ion adsorbent is o-hydroxybenzyl alcohol, and the pore diameter of the cesium ion adsorbent is 3.19 nm.

[0079] The present embodiment provides a preparation method of the cesium ion adsorbent, and the specific steps include:

[0080] Under a nitrogen atmosphere, o-hydroxybenzyl alcohol (2.48g, 0.02mol) was dissolved in 50mL of dichloroethane, anhydrous ferric chloride (3.25g, 0.02mol) was added to react at 45°C for 5h, and then The reaction temperature was raised to 80°C for 19 hours; after the reaction, cooled to room temperature and suction filtered to obtain an insoluble black solid; the solid was sequentially used in 0.05mol L -1 Washed with hydrochloric acid solution for 2h, washed with ultrapure water until the filtrate was neutral, washed with methanol until the filtrate became clear, then the separated solid product was further extracted with methanol Soxhlet for 24h to remove the ...

Embodiment 3

[0082] This embodiment provides a cesium ion adsorbent, the raw material of the cesium ion adsorbent is m-hydroxybenzyl alcohol, and the pore diameter of the cesium ion adsorbent is 3.91 nm.

[0083] The present embodiment provides a preparation method of the cesium ion adsorbent, and the specific steps include:

[0084] Under nitrogen atmosphere, m-hydroxybenzyl alcohol (2.48g, 0.02mol) was dissolved in 50mL of dichloroethane, anhydrous ferric chloride (3.25g, 0.02mol) was added to react at 45°C for 5h, and then The reaction temperature was raised to 80°C for 19 hours; after the reaction, cooled to room temperature and suction filtered to obtain an insoluble black solid; the solid was sequentially used in 0.05mol L -1 Washed with hydrochloric acid solution for 2h, washed with ultrapure water until the filtrate was neutral, washed with methanol until the filtrate became clear, then the separated solid product was further extracted with methanol Soxhlet for 24h to remove the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com