Preparing method of Gamma-ureidopropyl modified aerogel

A technology of ureapropyl and aerogels, which is applied in the field of preparation of low-cost modified aerogels, can solve the problem of low adsorption capacity, and achieve the effect of high specific surface area and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

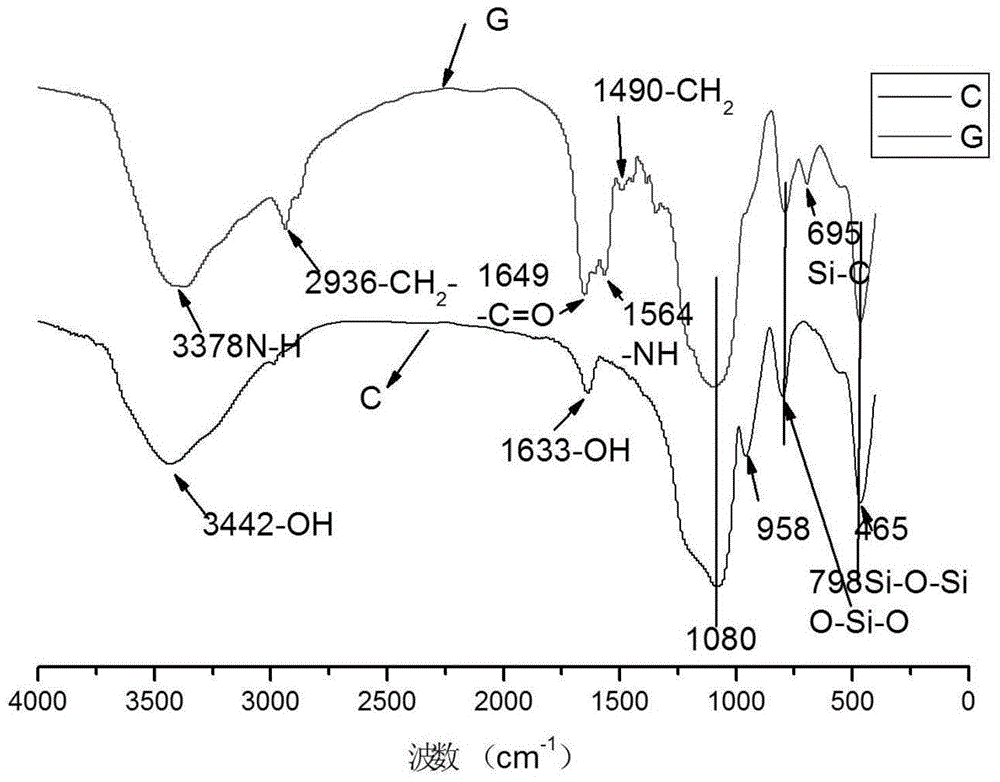

[0023] Prepare a water glass solution according to the mass ratio of potassium water glass to water as 1:1, pour it into an ion exchange column to obtain a silica sol with a pH value of 2, add an appropriate amount of NaOH catalyst, adjust the pH value to 5.5, let it stand, gel. After 4 hours of gelation, add Gamma-ureapropyl triethoxysilane to anhydrous methanol with a volume ratio of 1:1 to modify the solution, the volume of the modified solution is 5 times the volume of the gel, and the modification time is 2 days , the modification temperature is 65 ℃, after the modification, the solution is replaced with anhydrous methanol solution, the temperature is 65 ℃, until the pH value is 6. use C0 2 Supercritical Drying of Gamma-Ureapropyl Modified SiO 2 The gel dries. When dry, C0 2 The pressure was controlled at 8MPa, the temperature was controlled at 45°C, and the supercritical drying time was 48h to obtain a Gamma-ureapropyl modified aerogel product. figure 1 It can be se...

Embodiment 2

[0025] The water glass solution was prepared according to the mass ratio of sodium water glass and water to 1:5, poured into the ion exchange column to obtain a silica sol with a pH value of 3, an appropriate amount of ammonia water catalyst was added, the pH value was adjusted to 6.5, and it was allowed to stand for condensation. glue. After gelling for 1 hour, add Gamma-ureapropyltrimethoxysilane to absolute ethanol and water in a ratio of 1:10:0.3 to modify the solution, the volume of which is 1 times the volume of the gel, and the modification time is 10 days. The modification temperature is 25°C, after the modification, the solution is replaced with anhydrous ethanol solution, and the temperature is 25°C until the pH value is 7. use C0 2 Supercritical Drying of Gamma-Ureapropyl Modified SiO 2 The gel dries. When dry, C0 2 The pressure was controlled at 12MPa, the temperature was controlled at 50°C, and the supercritical drying time was 72h to obtain a Gamma-ureapropyl...

Embodiment 3

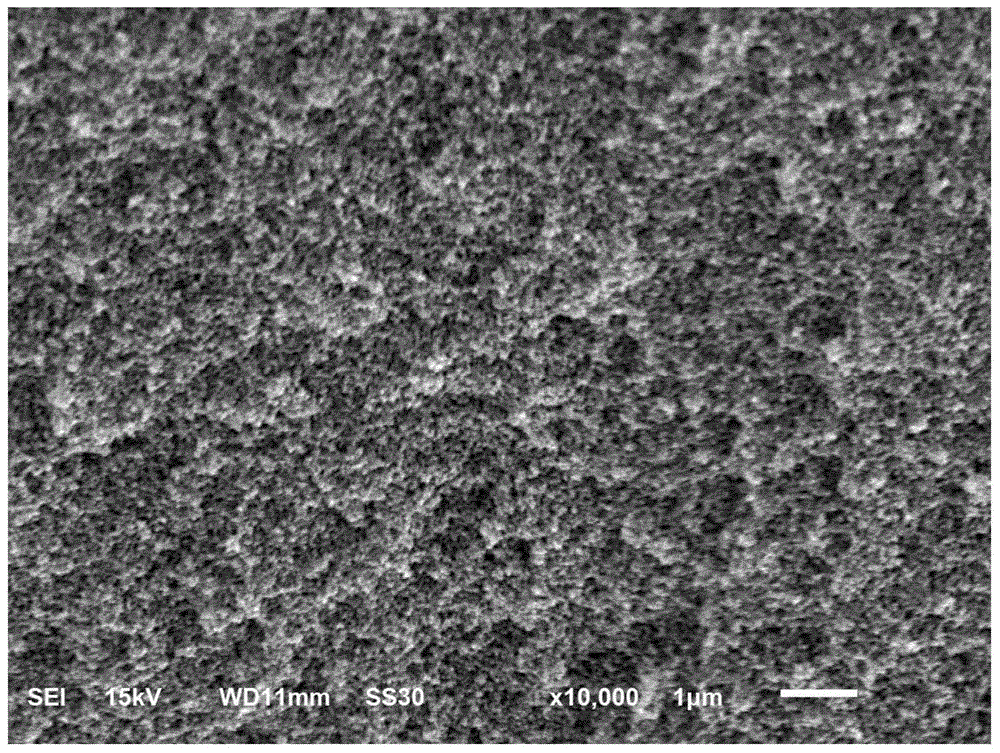

[0027] The water glass solution was prepared according to the mass ratio of sodium water glass and water as 1:4, poured into the ion exchange column to obtain a silica sol with a pH value of 2.5, and an appropriate amount of ammonia water catalyst was added to adjust the pH value to 6. glue. After 3 hours of gelation, add Gamma-ureapropyl triethoxysilane to anhydrous ethanol and water in a ratio of 1:3:0.1 to modify the solution, the volume of which is 1 times the volume of the gel, and the modification time is 5 days , the modification temperature is 45 ℃, after the modification, the solution is replaced with anhydrous ethanol solution, the temperature is 45 ℃, until the pH value is 6. Gamma-ureapropyl-modified SiO using ethanol supercritical drying 2 The gel dries. When drying, the pressure is controlled at 9MPa, the temperature is controlled at 250°C, and the holding time is 2h to obtain a Gamma-ureapropyl modified aerogel product. The prepared Gamma-ureapropyl modified S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com