Preparation method and application of nonmetal doped stainless steel mesh composite material

A technology of stainless steel mesh and composite materials, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as inability to produce metal nanoparticles on a large scale, cumbersome preparation process, and loss of active centers , to achieve excellent electron transfer ability, rich pore structure, and enhanced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this example, firstly, a nitrogen-doped metal nanoparticle-loaded stainless steel mesh composite material was prepared according to the following steps.

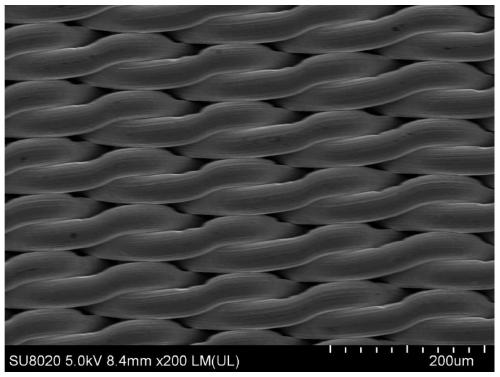

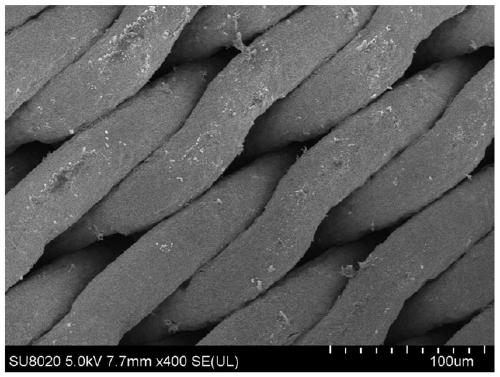

[0036]1. Pretreatment of stainless steel: put 1.4g of 2000-mesh stainless steel mesh in ethanol and aqueous solution to remove surface impurities by ultrasonic, then put it in a mixed solution of 1M lithium chloride monohydrate and 1M phosphoric acid, and conduct 2h at 120°C. After activation treatment, it is washed with water several times until neutral and then dried for later use.

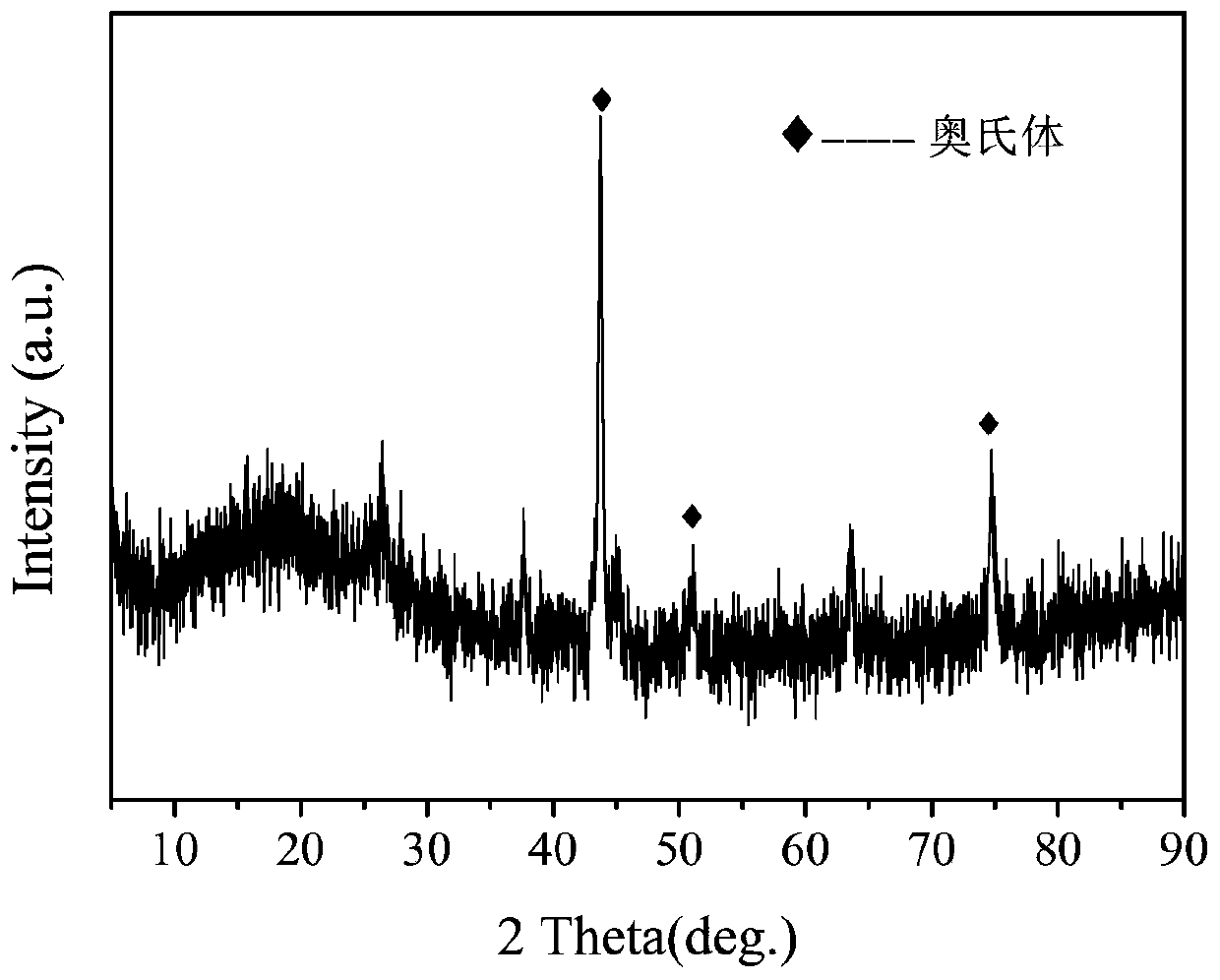

[0037] 2. Loading of non-metallic elements: Weigh 2g of melamine and the pretreated stainless steel mesh and place them in a quartz boat, then transfer the whole to a tubular resistance furnace, perform calcination and pyrolysis under the protection of an inert gas, and cool to At room temperature, the target product was obtained. Among them, the process of calcination and pyrolysis is to raise the temperature to 700° C. at a heatin...

Embodiment 2

[0049] In this example, a non-metal-doped stainless steel mesh composite material was prepared in the same manner as in Example 1, the only difference being that 2 g of dicyandiamide was used instead of 2 g of melamine to obtain the target non-metal-doped stainless steel mesh composite material.

[0050] Construct the organic pollutant catalytic reaction device identical with embodiment 1 with the nonmetal-doped stainless steel mesh composite material of the present embodiment, process following organic pollutant solution: the golden orange II solution simulation organic pollutant waste water (V of preparation 20mg / L =1000 mL), and 200 mg of oxidant permonomonosulfate (PMS) was added at the same time, and the degradation experiment was carried out by using an organic pollutant catalytic reaction device. After testing, the degradation rate of organic pollutant Golden Orange II can reach 100%.

Embodiment 3

[0052] In this example, a non-metal-doped stainless steel mesh composite material was prepared in the same manner as in Example 1, the only difference being that 2 g of urea was used instead of 2 g of dicyandiamide to obtain the target product non-metal-doped stainless steel mesh composite material.

[0053] Construct the organic pollutant catalytic reaction device identical with embodiment 1 with the nonmetal-doped stainless steel mesh composite material of the present embodiment, process following organic pollutant solution: the golden orange II solution simulation organic pollutant waste water (V of preparation 20mg / L =1000 mL), and 200 mg of oxidant permonomonosulfate (PMS) was added at the same time, and the degradation experiment was carried out by using an organic pollutant catalytic reaction device. After testing, the degradation rate of organic pollutant Golden Orange II can reach 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com