In-mould heat transfer film of elastic toy ball and production method of in-mould heat transfer film

A production method and technology of toy balls, which are applied in the directions of reproduction/marking methods, printing, household appliances, etc., can solve the problems of increasing the production cost of thermal transfer film, difficult to deal with plastic waste, difficult to recycle, etc., and meet the requirements of low equipment, The effect of avoiding plastic waste and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

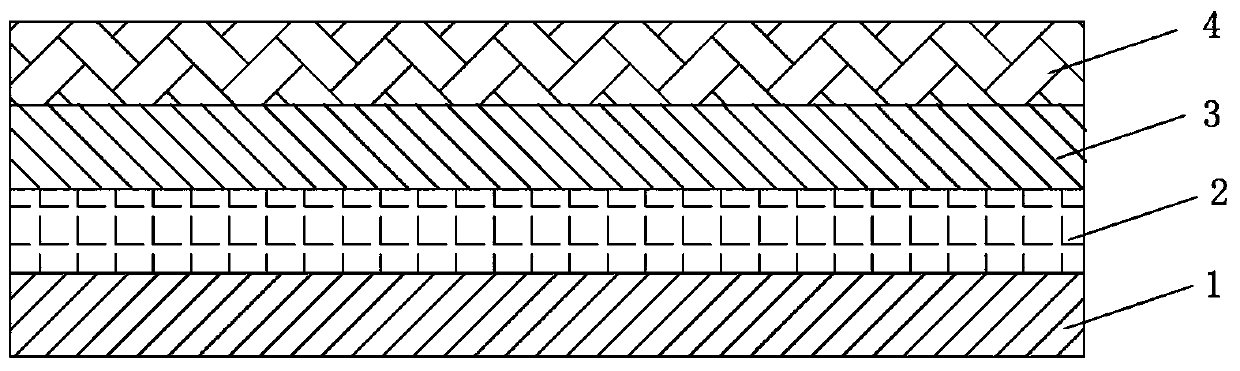

[0023] Embodiment 1, choosing a PVC film with a thickness of 50 microns as the film base layer 1, the release layer 2 with the waxy material as the main component, the printing coating 3 with the resin material as the main component, which are successively arranged on the film base upper surface, Transfer ink layer 4.

[0024] Preparation of release agent and coating of release layer: in weight ratio, the components of release agent include carnauba wax 10%, EVA resin 0.5%, xylene 50%, ethyl acetate 39.5%; carnauba wax , EVA resin mixed with solvent, heated to about 40°C and stirred to dissolve, the selected EVA resin has a vinyl acetate content of 18% to 20%, and a softening point of 77°C to 80°C; the coating method of the release layer 2 is as follows: Roll coater coating, anilox roll screen line: 150 lines, release layer 2 thermal coating, that is, the solvent-based release agent in the ink fountain is heated and kept at about 30°C for coating, drying conditions in the oven...

Embodiment 2

[0027] Embodiment 2, choosing a PVC film with a thickness of 100 microns as the film base layer 1, a release layer 2 with a waxy material as the main component, a printing coating 3 with a resin material as the main component, and Transfer ink layer 4.

[0028] Preparation of release agent and coating of release layer: in weight ratio, the components of release agent include petroleum wax 9%, EVA resin 1.0%, xylene 60%, ethyl acetate 30%; petroleum wax, EVA Mix the resin with the solvent, heat to about 40°C and stir to dissolve, stir and mix well, the melting point of the selected petroleum wax is 90°C, the selected EVA resin has a vinyl acetate content of 10% to 12%, and a softening point of 61°C to 63°C; Coating method of the type layer: use an anilox roller coater to coat, the anilox roller screen line: 300 lines, and the release layer is thermally coated, that is, the solvent-based release agent in the ink fountain is heated and kept at about 40°C for coating. Cloth, unde...

Embodiment 3

[0031] Embodiment 3, choosing a PVC film with a thickness of 100 microns as the film base layer 1, the release layer 2 with waxy material as the main component, the printing coating 3 with the resin material as the main component, which are arranged on the film base layer upper surface successively Transfer ink layer 4.

[0032] Preparation and coating of release agent: in weight ratio, the components of release agent include carnauba wax 7%, EVA resin 0.5%, xylene 69.5%, ethyl acetate 23%; carnauba wax, EVA resin Mix with a solvent, heat to about 40°C and stir to dissolve. The selected EVA resin has a vinyl acetate content of 10% to 12%, and a softening point of 61°C to 63°C. The coating method of the release layer is as follows: use an anilox roller coater Coating, anilox roller screen line 300 lines, thermal coating of the release layer, that is, the solvent-based release agent in the ink fountain is heated and kept at about 40°C, and the coating is carried out, the drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com