A nitrogen-containing treatment and discharge system for coating wastewater

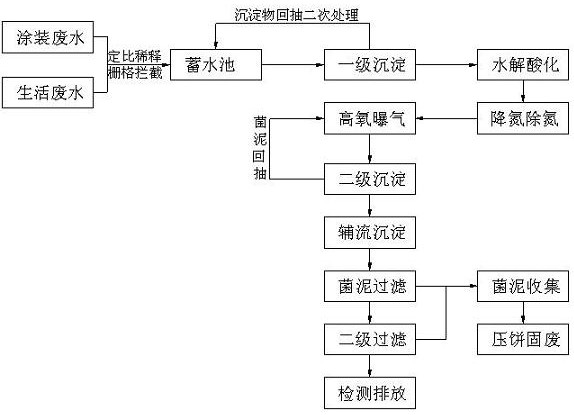

A technology for coating wastewater and discharge system, which is applied in the field of energy-saving sewage treatment system and nitrogen-containing treatment and discharge system of coating wastewater, which can solve the environmental occasions that cannot use a large amount of treatment, the treatment of organic matter is not thorough enough, and the circulation system is few, etc. problems, achieve good activity and intermittent variability, optimal aeration decomposition effect, and reduce maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

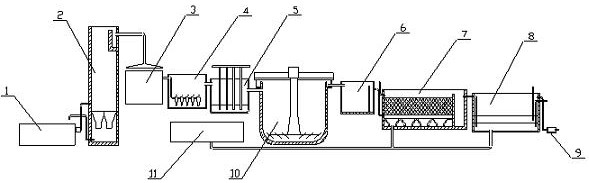

[0054] A nitrogen-containing treatment and discharge system for coating wastewater according to the present invention is realized as follows, including a water storage tank (1), a sedimentation tank (2), a hydrolysis and acidification tank (3), an anaerobic tank (4), and an aeration tank (5). ), auxiliary flow sedimentation tank (6), filter tank (7), sand filter tank (8), detection tank (9), bacterial sludge sedimentation tank (10) and sludge collection tank (11), the reservoir ( 1) Two liquid accommodating areas are provided, and the two liquid accommodating areas are respectively provided with an introduction pipe and a discharge pipe, the introduction pipe of the reservoir (1) is provided with an intercepting grid, and the discharge pipe on the reservoir (1) The sedimentation tank (2) is communicated with the sedimentation tank (2) through a high-pressure pump. The sedimentation tank (2) is in and out from the bottom, and the pool walls around the bottom of the sedimentation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com