Light-heat conduction and lightweight porous ceramic for daily use, and preparation method thereof

A low thermal conductivity, lightweight technology, applied in the direction of ceramic products, applications, household appliances, etc., can solve the problems of high porosity and strength, low flexural strength and compressive strength, difficult control of sintering process, etc., to avoid The effect of scalding the user, low thermal conductivity, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

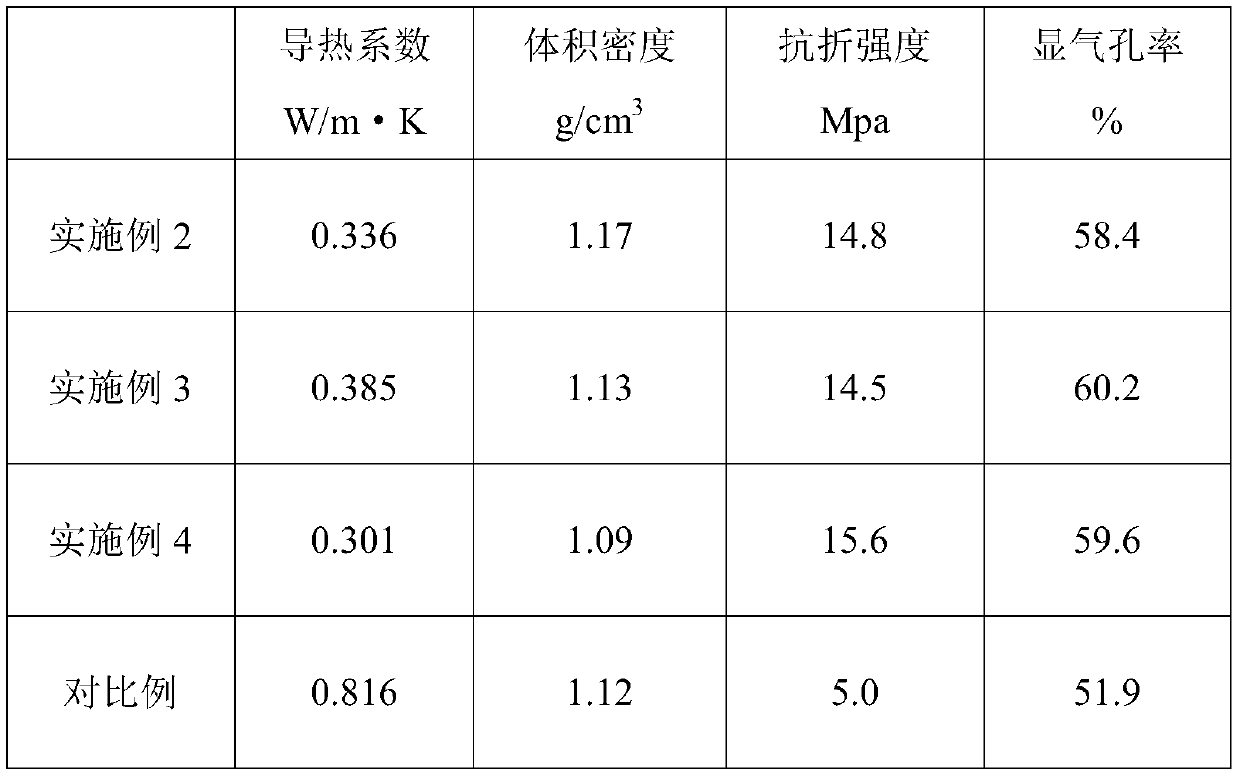

Examples

Embodiment 1

[0035] A light-weight porous daily-use ceramic with low thermal conductivity, which is made of the following raw materials in parts by weight: 60-70 parts of lithium-based bentonite powder, 14-20 parts of lithium-based bentonite powder, 8-13 parts of bauxite powder, and γ-type 6-11 parts of aluminum oxide, 12-18 parts of quartz powder, 5-9 parts of aluminum silicate fiber tube, 70-90 parts of water, 0.9-1.5 parts of water reducing agent, 1.8-3.4 parts of foaming agent, foam stabilizer 1.1-1.7 parts of agent, 2-4.5 parts of dispersant.

[0036] In this embodiment, a method for preparing the described low-thermal-conductivity lightweight porous ceramics for daily use includes the following steps:

[0037] A. Weigh lithium feldspar powder, lithium-based bentonite powder, bauxite powder, γ-type aluminum oxide, quartz powder, aluminum silicate fiber tube, water, water reducing agent, foaming agent, foam stabilizer, etc. in parts by weight. agent, dispersant;

[0038] B. First dis...

Embodiment 2

[0042] A light-weight porous daily-use ceramic with low thermal conductivity, made of the following raw materials in parts by weight: 60 parts of lithium feldspar powder, 14 parts of lithium-based bentonite powder, 8 parts of bauxite powder, and 6 parts of γ-type aluminum oxide , 12 parts of quartz powder, 5 parts of aluminum silicate fiber tube, 70 parts of water, 0.9 part of water reducing agent, 1.8 parts of foaming agent, 1.1 parts of foam stabilizer, and 2 parts of dispersing agent.

[0043] In this embodiment, the foaming agent is sodium dodecyl sulfonate.

[0044] In this embodiment, the foam stabilizer is a mixture of hydroxyl-terminated polymethicone oil and coconut acid monoethanolamide.

[0045]In this embodiment, the mass ratio of hydroxyl-terminated polymethicone oil and coconut acid monoethanolamide in the mixture of hydroxyl-terminated polymethicone oil and coconut acid monoethanolamide is 1:0.6.

[0046] In this embodiment, the water reducer is a mixture of wa...

Embodiment 3

[0056] A light-weight porous daily-use ceramic with low thermal conductivity, made of the following raw materials in parts by weight: 70 parts of lithium feldspar powder, 20 parts of lithium-based bentonite powder, 13 parts of bauxite powder, and 11 parts of gamma-type aluminum oxide , 18 parts of quartz powder, 9 parts of aluminum silicate fiber tube, 90 parts of water, 1.5 parts of water reducer, 3.4 parts of foaming agent, 1.7 parts of foam stabilizer, and 4.5 parts of dispersant.

[0057] In this embodiment, the foaming agent is sodium dodecyl sulfonate.

[0058] In this embodiment, the foam stabilizer is a mixture of hydroxyl-terminated polymethicone oil and coconut acid monoethanolamide.

[0059] In this embodiment, the mass ratio of hydroxyl-terminated polymethicone oil and coconut acid monoethanolamide in the mixture of hydroxyl-terminated polymethicone oil and coconut acid monoethanolamide is 1:0.75.

[0060] In this embodiment, the water reducer is a mixture of wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com