Decorative panel used in decoration and manufacturing method thereof

A technology for decorative panels and manufacturing methods, applied in the direction of chemical instruments and methods, applications, household components, etc., can solve problems such as time-consuming, poor quality, and complicated processes, and achieve the effect of beautiful appearance, high orientation rate, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

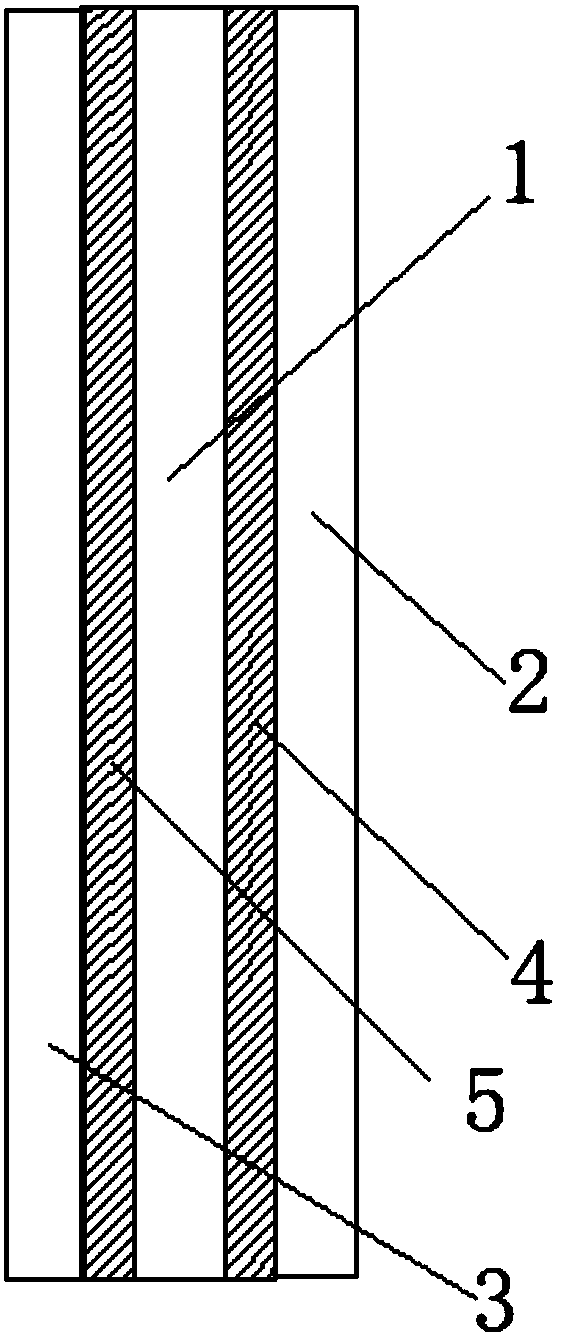

[0019] like figure 1 As shown, a decorative panel used in decoration and a manufacturing method thereof, the decorative panel includes: a substrate layer 1, a panel layer 2 is provided on one side of the substrate layer 1, and a bottom layer 3 is provided on the other side. The panel layer 2 is fixed on the substrate layer 1 through the upper bonding layer 4, and the base layer 3 is fixed on the substrate layer 1 through the lower bonding layer 5, and its decorative panel preparation method comprises the following steps:

[0020] (1) Raw material preparation: cutting the crop stalks into 80-150mm raw materials for later use;

[0021] (2) Drying and sorting: the raw materials are sent to the dryer for drying through the feeder, and the dried raw materials are sent to the airflow sorting machine through the air supply system for sorting, and after sorting, they are sent to the screening machine for screening, and then passed through the surface The core layer belt conveyor is s...

Embodiment 1

[0027] A decorative panel used in decoration and a manufacturing method thereof, comprising the following steps:

[0028] (1) Raw material preparation: cutting rice straw or wheat straw into 80mm raw materials for later use;

[0029] (2) Drying and sorting: the raw materials are sent to the dryer for drying through the feeder, and the outlet air temperature of the dryer is 100°C. Finally, it is sent to the screening machine for screening, and then sent to the surface core layer silo by the surface core layer belt conveyor;

[0030] (3) Sizing: The raw materials are quantitatively output from the silo. The mass ratio of crop straw and modified starch is 5 parts of plant straw and 25 parts of modified starch. They are sent to the drum mixer, and the mixer makes the incoming straw and heated modified starch fully Stir and adjust the ratio of modified starch according to the change of straw conveying amount;

[0031] (4) Slab paving: The slab paving is carried out through the pa...

Embodiment 2

[0037] A decorative panel used in decoration and a manufacturing method thereof, comprising the following steps:

[0038] (1) Raw material preparation: cutting rice straw or wheat straw into 150mm raw materials for later use;

[0039] (2) Drying and sorting: the raw materials are sent to the dryer for drying through the feeder, and the air outlet temperature of the dryer is 200°C during drying. Finally, it is sent to the screening machine for screening, and then sent to the surface core layer silo by the surface core layer belt conveyor;

[0040] (3) Glue sizing: The raw materials are quantitatively output from the silo. The mass ratio of crop straw and modified starch is 50 parts of plant straw and 40 parts of modified starch, and they are sent to the drum mixer. The mixer makes the incoming straw and heated modified starch fully Stir and adjust the ratio of modified starch according to the change of straw conveying amount;

[0041] (4) Slab paving: The slab paving is carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com