Test method for FPSO upper module model under simulated extreme sea condition

A test method and module model technology, applied in the field of offshore platform testing, can solve the problems of insufficient guidance for the design, construction and installation of FPSO upper modules, insufficient basis for results and conclusions, and threats to the safety of offshore oil and gas production. The effect of analyzing pre-judgment test results, fast synchronization processing speed, and strong adaptability to the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings.

[0029] Such as figure 1 , figure 2 , image 3 As shown, the present invention is a FPSO upper module model test method that simulates extreme sea conditions. The present invention will be further described with reference to the accompanying drawings.

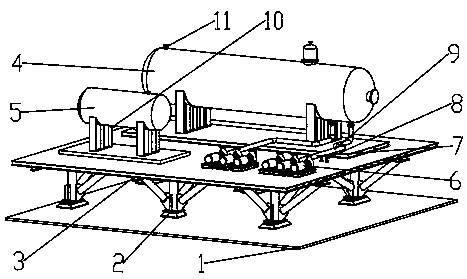

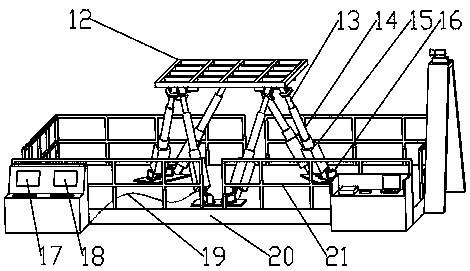

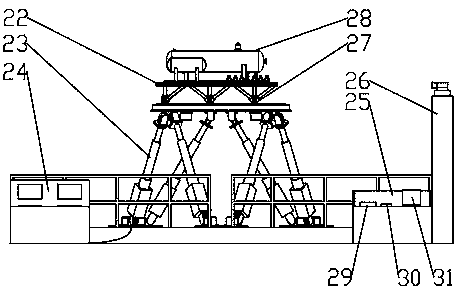

[0030] Such as figure 1 , figure 2 , image 3 As shown, the present invention is a FPSO upper module model test method that simulates extreme sea conditions. It mainly consists of deck 1, modular buttress 2, modular deck 3, crude oil processor 4, crude oil storage tank 5, transfer pump 6, pipeline 7, pipe Bracket 8, butterfly valve 9, stop valve 10, head flange 11, square steel rectangular platform 12, electric cylinder 13, displacement sensor 14, motor 15, double Hook hinge 16, data input interface 17, data output interface 18, line Cable 19, support platform 20, protective fence 21, FPSO upper module overall model 22, electric six-deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com