Health blueberry concentrated solution and production technology thereof

A production process and a concentrated liquid technology, which are applied in the field of health-care blueberry concentrate and its production process, can solve problems such as loss of nutrients, and achieve the effects of mellow flavor, retention of nutrients and functional components, and rich fruit aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

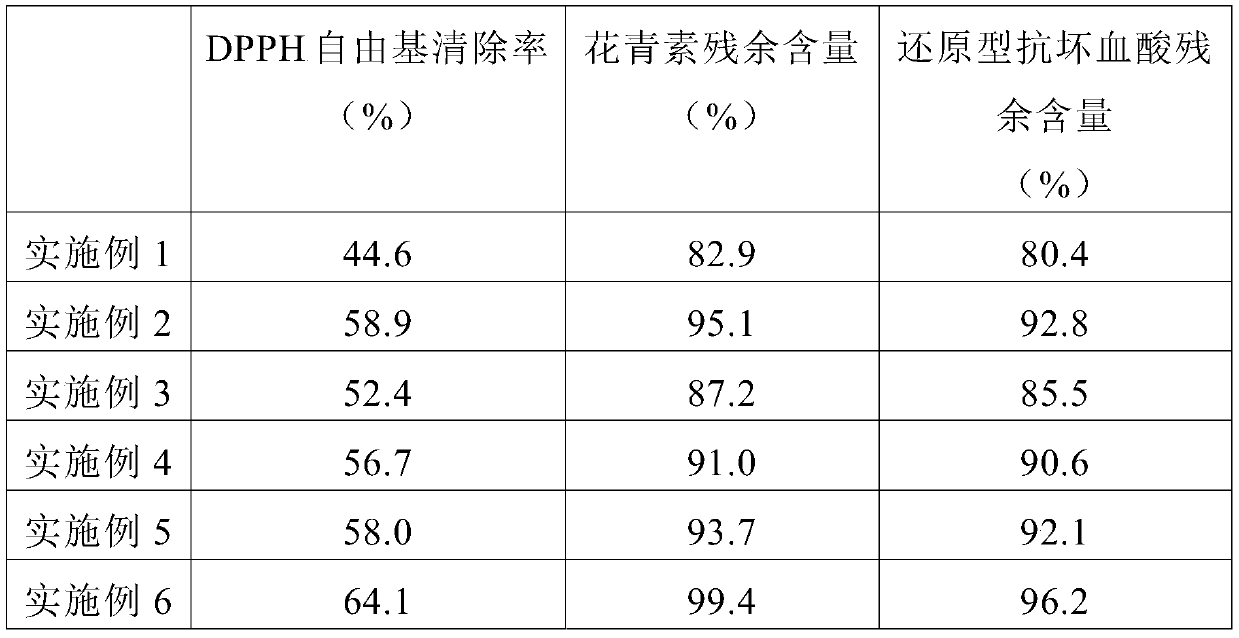

Examples

Embodiment 1

[0034] The production technology of health-care blueberry concentrate comprises the following steps:

[0035] (1) Clean the blueberries with water, place them for 3 hours in an environment with a temperature of 28°C and a relative humidity of 60%, and drain;

[0036] (2) Take 10 kg of drained blueberries and 90 kg of purified water and add them to a beater at a temperature of 2°C for 4 minutes to obtain a slurry;

[0037] (3) Filtrate the slurry using a plate and frame filter to obtain a filtrate;

[0038] (4) Concentrate the filtrate in vacuum at a temperature of 50°C and an absolute pressure of 0.15 MPa to a soluble solid content of 60 Brix to obtain a concentrated solution;

[0039] (5) Heat and sterilize the concentrated solution at a temperature of 121° C. for 4 seconds, and then rapidly cool it to 30° C. at a cooling rate of 12° C. / s to obtain a health-care blueberry concentrated solution.

[0040] The rotating speed of the beating is 600 rpm.

[0041] The pore diamet...

Embodiment 2

[0043] The production technology of health-care blueberry concentrate comprises the following steps:

[0044](1) Clean the blueberries with water, place them for 3 hours in an environment with a temperature of 28°C and a relative humidity of 60%, and drain;

[0045] (2) Take 10 kg of drained blueberries, 90 kg of purified water, 0.5 kg of antioxidant silkworm chrysalis protein, and 0.15 kg of plant antioxidants and add them to a beater at a temperature of 2 ° C for 4 minutes to obtain a slurry;

[0046] (3) Filtrate the slurry using a plate and frame filter to obtain a filtrate;

[0047] (4) Concentrate the filtrate in vacuum at a temperature of 50°C and an absolute pressure of 0.15 MPa to a soluble solid content of 60 Brix to obtain a concentrated solution;

[0048] (5) Heat and sterilize the concentrated solution at a temperature of 121° C. for 4 seconds, and then rapidly cool it to 30° C. at a cooling rate of 12° C. / s to obtain a health-care blueberry concentrated solution...

Embodiment 3

[0056] The production technology of health-care blueberry concentrate comprises the following steps:

[0057] (1) Clean the blueberries with water, place them for 3 hours in an environment with a temperature of 28°C and a relative humidity of 60%, and drain;

[0058] (2) Take 10 kg of drained blueberries, 90 kg of purified water, 0.5 kg of silkworm chrysalis protein, and 0.15 kg of plant antioxidants and add them to a beater at a temperature of 2 ° C for 4 minutes to obtain a slurry;

[0059] (3) Filtrate the slurry using a plate and frame filter to obtain a filtrate;

[0060] (4) Concentrate the filtrate in vacuum at a temperature of 50°C and an absolute pressure of 0.15 MPa to a soluble solid content of 60 Brix to obtain a concentrated solution;

[0061] (5) Heat and sterilize the concentrated solution at a temperature of 121° C. for 4 seconds, and then rapidly cool it to 30° C. at a cooling rate of 12° C. / s to obtain a health-care blueberry concentrated solution.

[0062]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com