Wet desulfurization system and wet desulfurization method

A wet desulfurization and desulfurization tower technology, applied in the field of desulfurization, can solve the problems of limited flue gas temperature rise, difficult zero discharge of desulfurization wastewater, and the ability to eliminate white smoke needs to be improved, so as to increase the degree of unsaturation and achieve ultra-clean The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

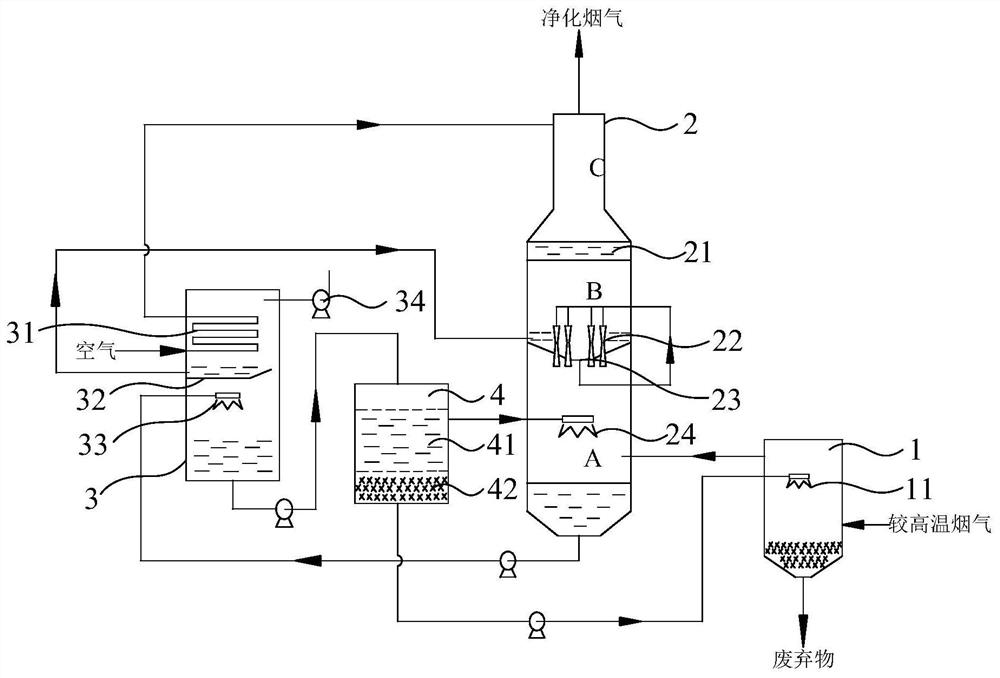

[0040] like figure 1 and figure 2 As shown, the embodiment of the present application provides a wet desulfurization system, including: a waste liquid evaporator 1, a desulfurization tower 2, a settling tank 4 and a negative pressure evaporator 3;

[0041] The interior of the desulfurization tower 2 includes an outlet section C, a washing and demisting section B, and a cooling and absorbing section A from top to bottom, and a demister assembly is arranged inside the washing and demisting section B, wherein the demist assembly includes a mist catcher 21 And the mist eliminator 22, the upper space of the cooling absorption section A is provided with a first injection part 24;

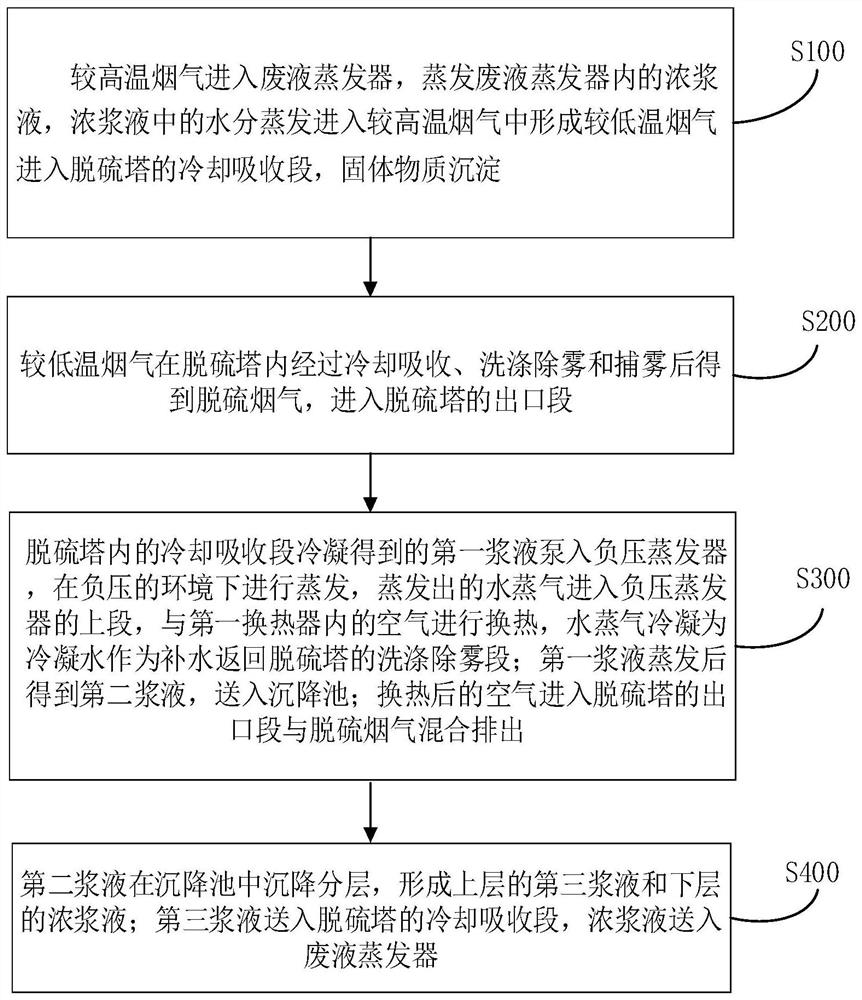

[0042] The flue gas inlet of the waste liquid evaporator 1 is used to feed the flue gas to be treated, and the flue gas outlet of the waste liquid evaporator 1 is connected with the cooling absorption section A of the desulfurization tower 2; Part 11; the higher temperature flue gas enters the waste li...

Embodiment 2

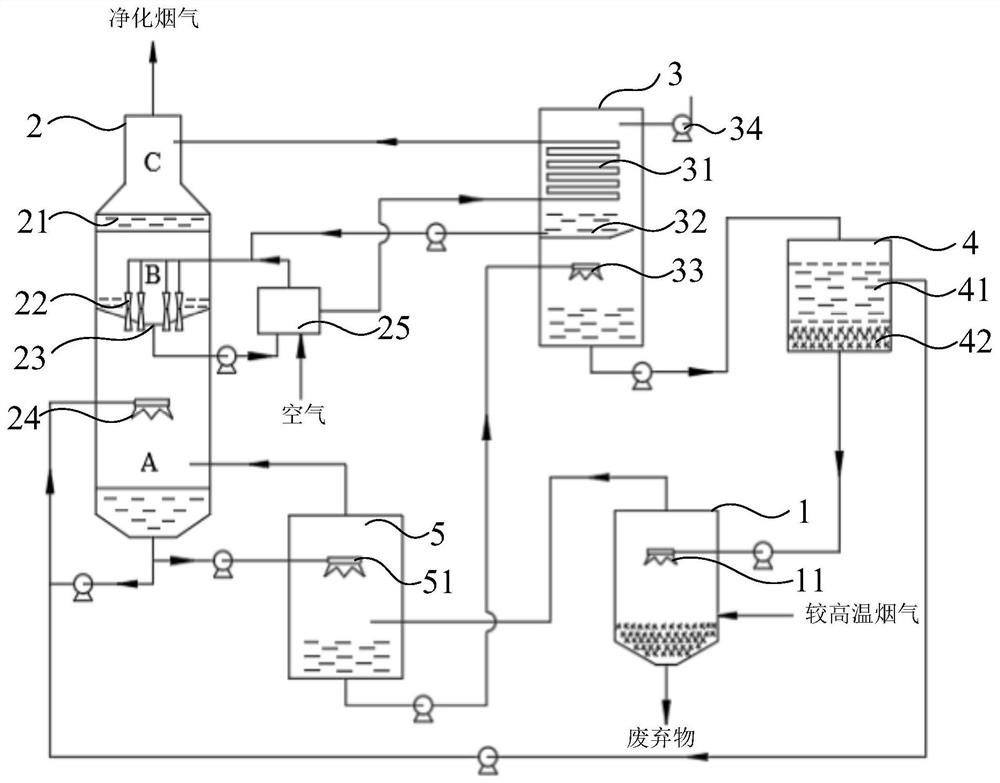

[0064] like image 3 and Figure 4 As shown, the embodiment of the present application provides a wet desulfurization system, in addition to the structural features in Embodiment 1, it also includes a second heat exchanger 25, and the washing and demisting section B is provided with a liquid collection port 23, and the liquid collection Port 23 communicates with the first medium inlet of the second heat exchanger 25, and the first medium outlet of the second heat exchanger 25 communicates with the demister 22; The second medium outlet of the second heat exchanger 25 communicates with the inlet of the first heat exchanger 31 .

[0065] The second heat exchanger 25 adopts a heat exchange type with a wide flow channel, and can be a wide flow channel heat exchanger such as a tube type, a plate type, a heat pipe type, and a shell-and-tube type. The material of the heat exchanger can be selected from 314L, 2205 stainless steel, fluoroplastic, Corrosion-resistant materials such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com