Catalyst for synthesizing 1,5-pentanediol and preparation method of catalyst

A catalyst, pentanediol technology, applied in the field of biomass, can solve the problems of unsuitability for large-scale industrial production, cumbersome process, low selectivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

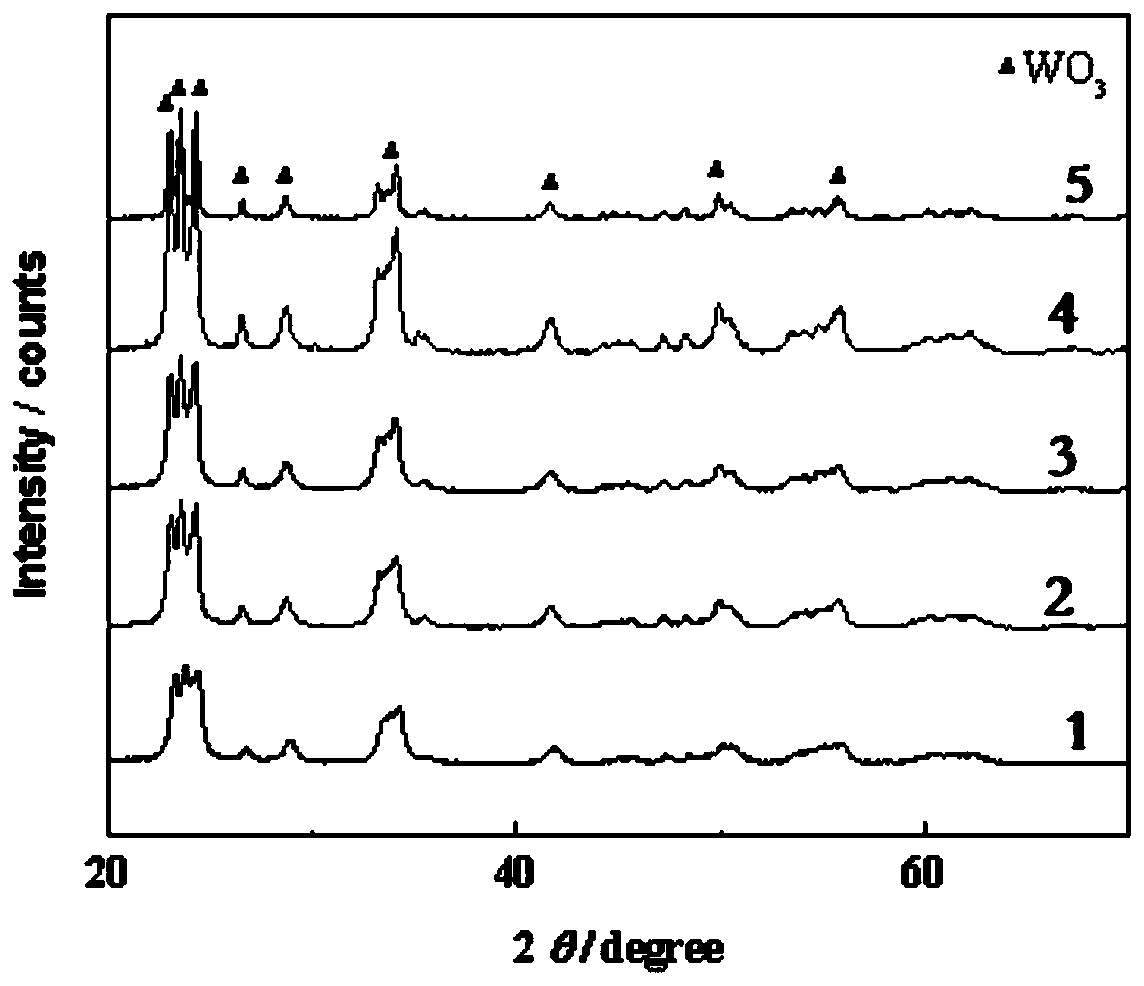

Embodiment 1

[0022] Weigh 3.3826g of tetraethyl silicate, 2.0106g of ammonium metatungstate and 5.1273g of citric acid in 25mL of ultrapure water, stir at 40°C until gelatinous, and place in an oven at 110°C for drying Moisture, after drying, place in a tube furnace and roast at 400°C for 2h under nitrogen atmosphere, cool to room temperature and place in a muffle furnace for 4h at 550°C to obtain 0.5WO 3 -SiO 2 . Weigh the chloroplatinic acid solution according to a certain metering ratio and immerse it in the prepared 0.5WO 3 -SiO 2 After standing for 4 hours, stir and dry the water at 60°C. After drying, place it in a muffle furnace and bake at 400°C for 2 hours to obtain 5%wtPt / 0.5WO 3 -SiO 2 .

Embodiment 2

[0024] Weigh 3.3826g of tetraethyl silicate, 3.2817g of ammonium metatungstate and 6.2276g of citric acid in 25mL of ultrapure water, and the other conditions are the same as in Example 1 to prepare 5%wtPt / 0.8WO 3 -SiO 2 .

Embodiment 3

[0026] Weigh respectively the tetraethyl silicate of 3.3826g, the ammonium metatungstate of 4g and the citric acid of 6.8521g in the ultrapure water of 25mL, other conditions are identical with embodiment 1, prepare 5%wtPt / 1.0WO 3 -SiO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com