Metal and polymer welding device and welding method

A welding device and polymer technology, applied in welding equipment, welding equipment, auxiliary equipment, etc., can solve problems such as inaccurate control and influence on welding quality, and achieve the effects of preventing system overheating, easy operation, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

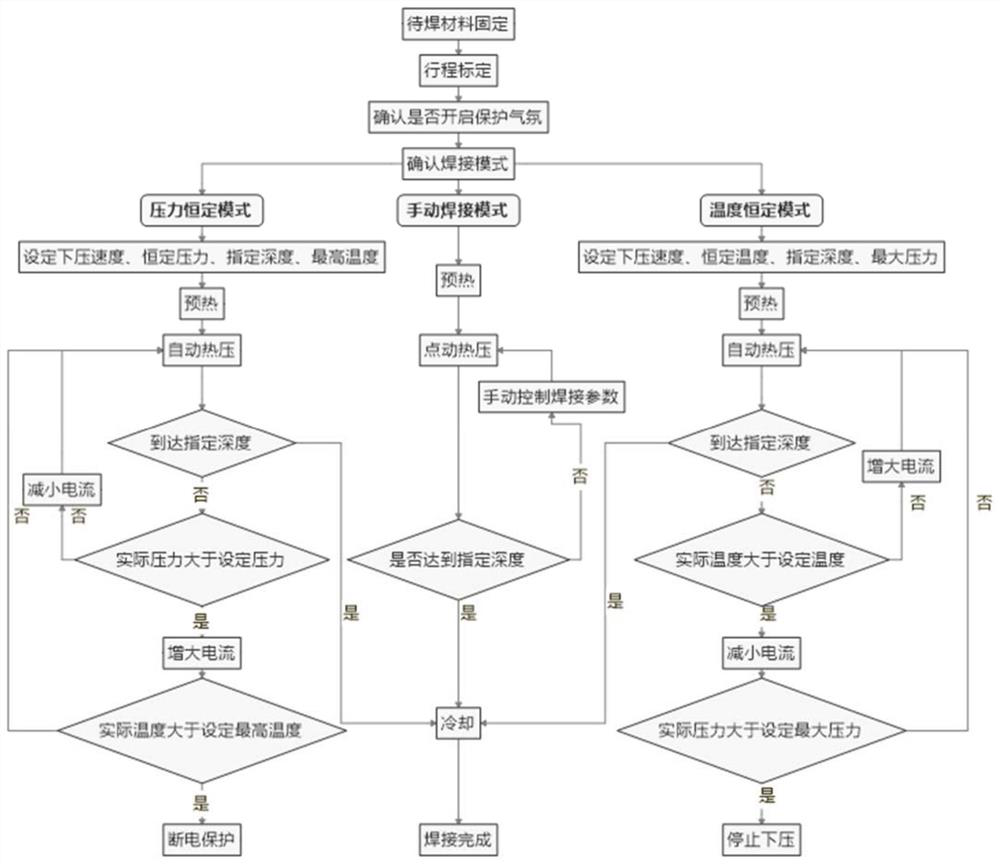

[0037]A metal and polymer welding device with automatic temperature control and pressure control. The welding device is mainly composed of an electric heating system, a pressure system, a workbench, an inflation system and a touch-type human-computer interaction interface system.

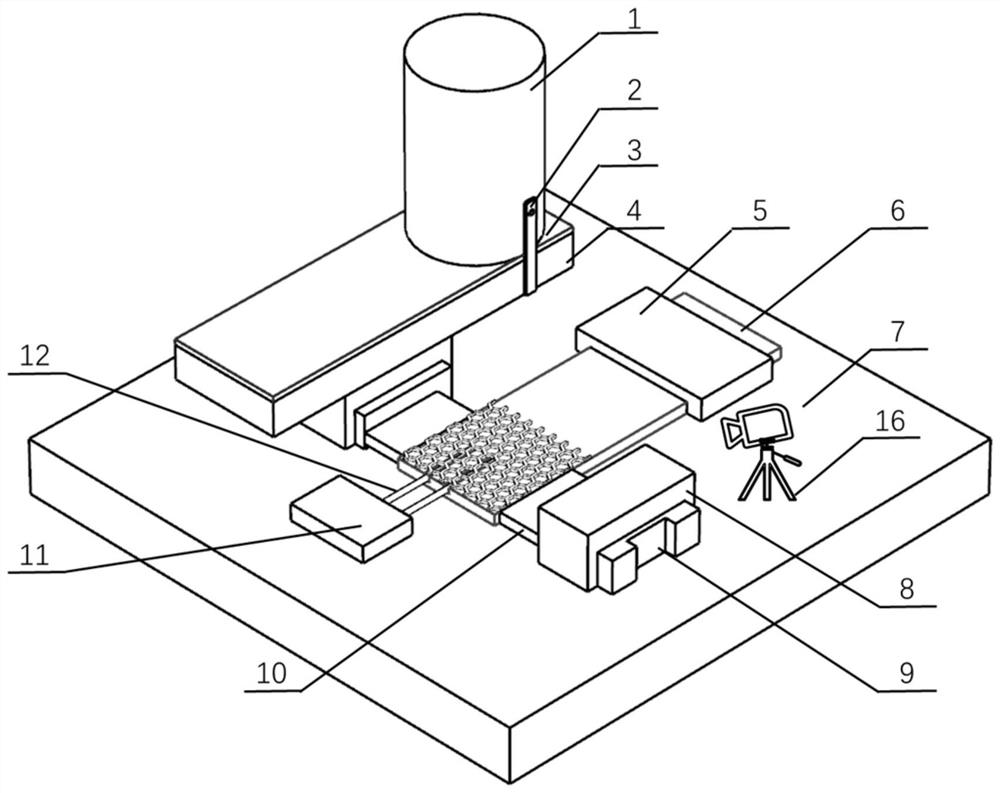

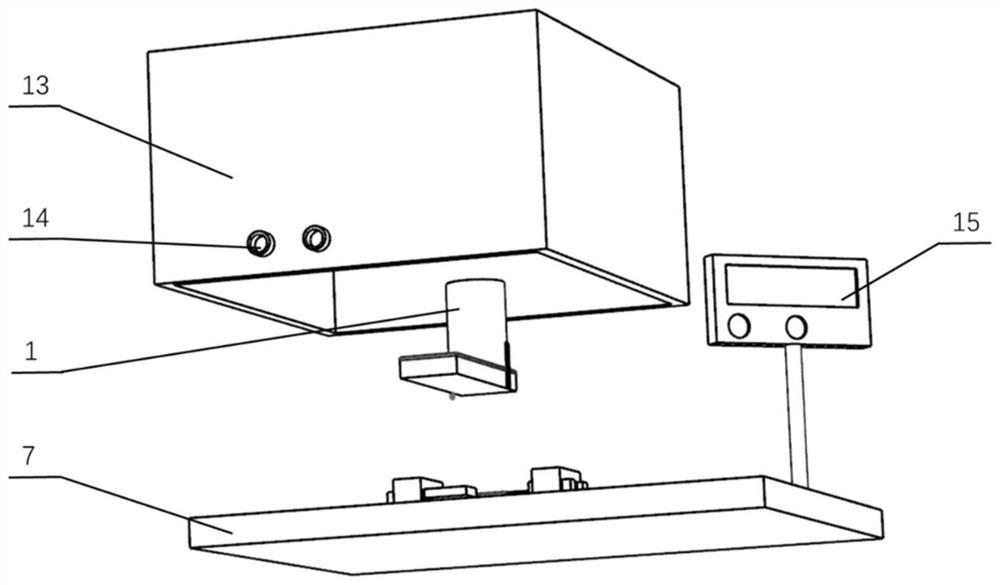

[0038] Such as Figure 1-2 As shown, an electric heating system and a touch-type human-computer interaction interface system 15 are fixed on the working platform 7 . The electric heating system includes a metal plate fixing device 5 , a conductive element fixing piece 8 , a copper wire 9 , a conductive element 10 , a thermocouple 12 , an infrared thermal imager 15 and a temperature data recorder 11 . The pressure system includes an indenter 1 with a built-in load cell, a spring clip 2 and a metal back plate 3 . The pressure system is suspended above the working platform 7 through a mechanism. The inflation system includes a sealing cover 13 and an air inlet 14. The sealing cover 13 can seal the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com