A hot pressing process for environment-friendly oriented strand board

A technology of oriented strand board and hot-pressing process, which is applied in the field of board manufacturing, can solve the problems of unstable quality of oriented strand board, high formaldehyde content of oriented strand board, easy occurrence of bubbling and delamination, etc., and achieve low scrap rate and fast press speed , the effect of not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Embodiment A kind of heat-pressing process of environment-friendly type oriented strand board

[0024] The invention provides a hot-pressing process for environment-friendly oriented strand board, which includes pre-pressing, water spraying, roller coating of release agent, and hot pressing;

[0025] (1) Preload:

[0026] The lower surface slab, the core layer slab and the upper surface slab are respectively pre-pressed by the rubber roller's own weight, and pre-pressed several times;

[0027] When paving the upper fine material layer slab, use the pre-pressing machine to pre-press the lower fine material layer slab, lower surface layer slab, core layer slab, upper surface layer slab and upper fine material layer slab five-layer slab , The pressure of the pre-compressor is 1.5MPa.

[0028] (2) Water spray:

[0029] The pre-pressed slab is sprayed with water to increase the moisture content of the upper and lower surfaces of the slab;

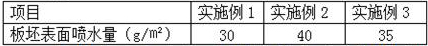

[0030] The amount of water spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com