Preparation method of graphene airgel, fe 3 o 4 /Graphene airgel and preparation method thereof

A graphene airgel and gel technology, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve problems such as poor structural integrity and low electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

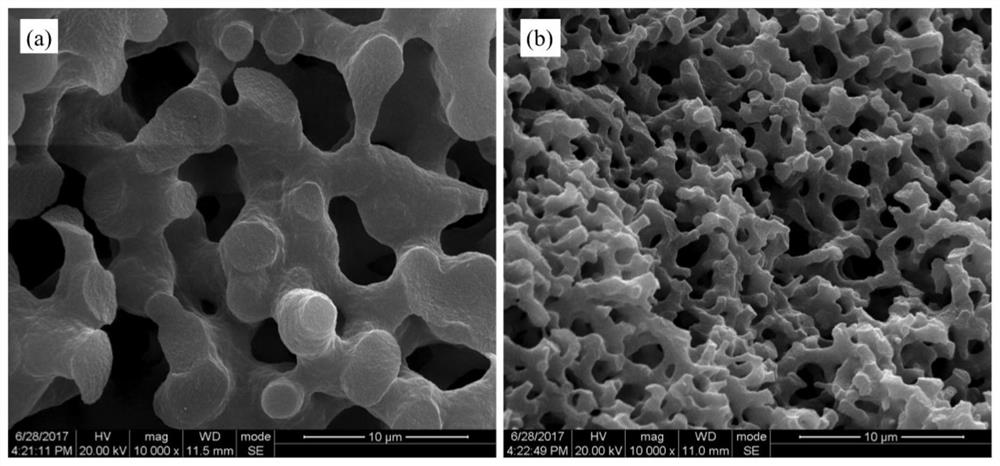

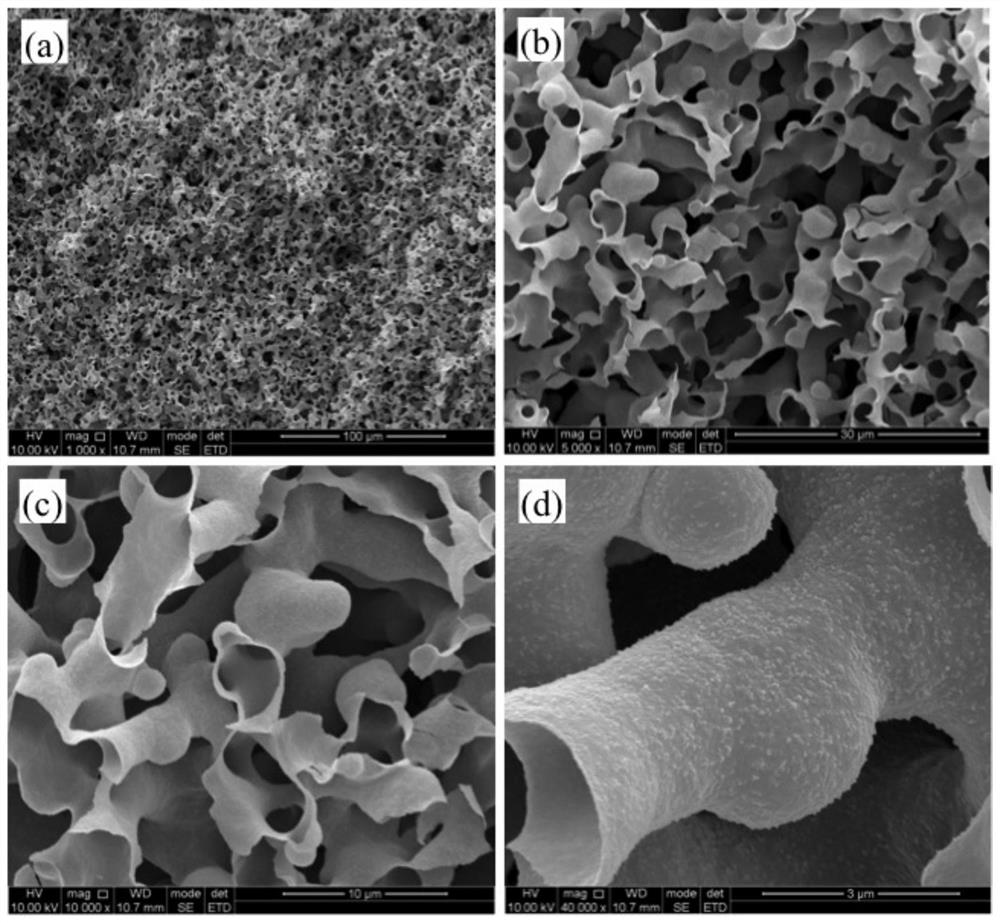

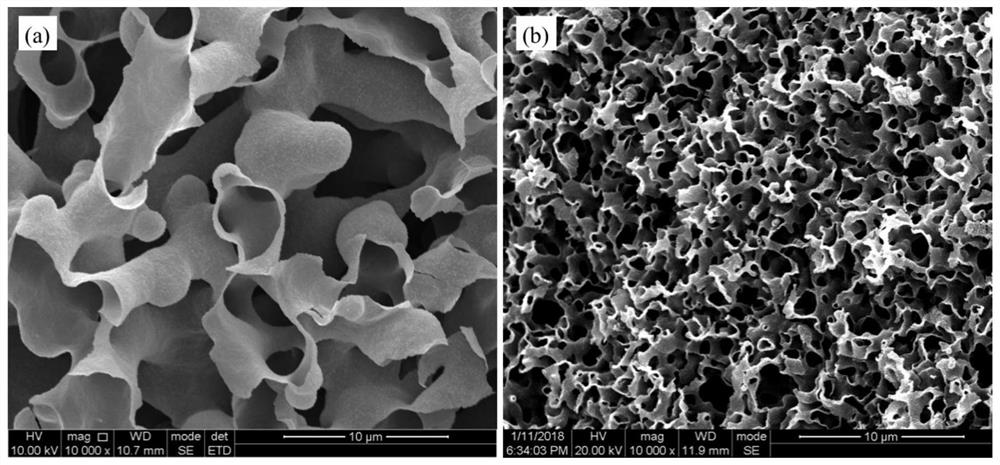

[0027] The preparation method of graphene airgel comprises the steps:

[0028] S10, preparing the silica porous framework:

[0029]S110, mixing the silicon source material and the phase separation inducer for acid hydrolysis to obtain a first hydrolyzate. In detail, silicon source material, acid, water (H 2 O) and the phase separation inducer are mixed sequentially according to the mass ratio of (6~10):(0.5~1.5):(8~12):(0.5~1), and the temperature is 0~15°C. Acid hydrolysis yields the first hydrolyzate.

[0030] Wherein, the silicon source material includes at least one of ethyl orthosilicate, methyl orthosilicate, methyltriethoxysilane and methyltrimethoxysilane, as long as it can be hydrolyzed to obtain silicon dioxide. The phase separation inducer includes polyethylene oxide, polyvinyl polypyrrolidone or polyacrylamide. Through the use of the phase separation inducer, the phase separation reaction of the homogeneous silicon-containing aqueous solution can occur under cer...

Embodiment 1

[0060] The preparation method of graphene airgel comprises the steps:

[0061] (1), tetraethyl orthosilicate (TEOS), nitric acid (HNO 3 ), water (H 2 O) and polyethylene oxide (PEO) are mixed sequentially according to the mass ratio of 8.5:1:10:0.8, and acid hydrolysis is carried out at a temperature of 0° C. to obtain the first hydrolyzate. Wherein, the molecular weight of polyethylene oxide (PEO) is 10,000.

[0062] (2) Pour the first hydrolyzate into a plastic mold and place it in an incubator at 60° C. to fully react for at least three days to obtain a silica skeleton.

[0063] (3) After washing the silica skeleton to neutrality, add ammonia solution with a concentration of 1mol / L for aging treatment for at least 24 hours, then wash the sample to neutrality, and control the temperature of the incubator at 40°C. After drying for 25 hours, a three-dimensional silica porous framework was obtained.

[0064] (4) Place the silica porous framework in an environment with a tem...

Embodiment 2

[0068] The preparation method of the graphene airgel provided in Example 2 is basically the same as the preparation method of the graphene airgel provided in Example 1, the difference being that the molecular weight of the polyethylene oxide (PEO) provided in Example 2 is 100,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com