Double-membrane-chamber membrane capacitance desalination device with continuous water production capacity

A technology of membrane capacitor and membrane chamber, which is applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve problems such as limited application and intermittent water discharge, and achieve improved current efficiency and continuous production water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

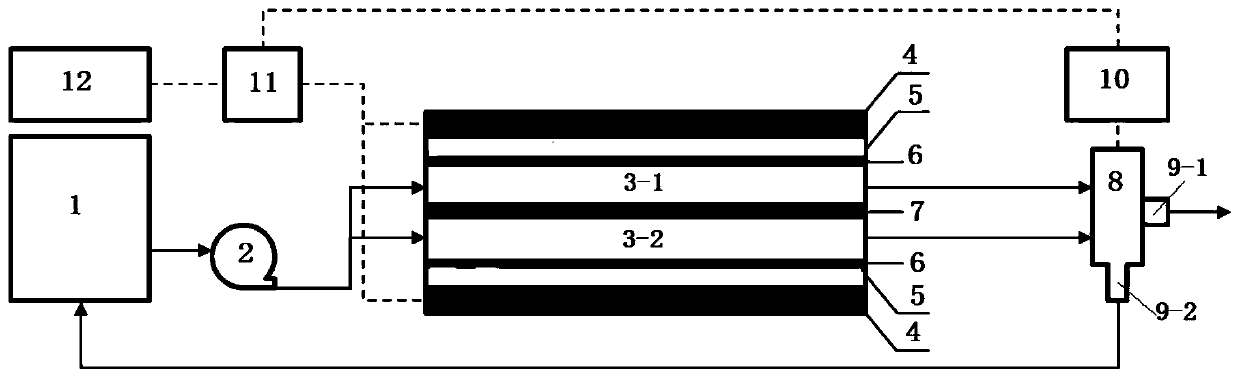

Embodiment 1

[0019] Embodiment The raw water is tap water, the conductivity is 158-170 μS / cm, and the turbidity is 0.8-1.1 NTU. Structural parameters of the double-membrane membrane capacitive desalination module: the distance between the cation exchange membrane and the anion exchange membrane is 0.5mm, the mass of activated carbon fiber cloth on both sides is 2.0g; the flow rate of fresh water and concentrated water is 1mL / min, the output voltage of the DC power supply It is 0.8V; the time relay controls the polarity reversal time to be 90min.

[0020] The experimental results show that: the current efficiency is ≥106%, the electric energy recovery rate is 58%, the conductivity of the clean water is ≤0.1μS / cm, and the turbidity is not detected. (GB / T12145-2016) standard.

Embodiment 2

[0022] Embodiment The raw water is tap water, the conductivity is 145-160 μS / cm, and the turbidity is 1.0-1.5 NTU. Structural parameters of the double-membrane membrane capacitive desalination module: the distance between the cation exchange membrane and the anion exchange membrane is 0.7mm, the mass of activated carbon fiber cloth on both sides is 2.0g; the flow rate of fresh water and concentrated water is 3mL / min, the output voltage of the DC power supply It is 1.0V; the time relay controls the polarity reversal time to be 90min.

[0023] The experimental operation results show that: the current efficiency is ≥108%, the electric energy recovery rate is 43%, the conductivity of the clean water is ≤0.1μS / cm, and the turbidity is not detected. (GB / T12145-2016) standard.

Embodiment 3

[0025] Embodiment The raw water is tap water, the conductivity is 157-183 μS / cm, and the turbidity is 1.2-1.5 NTU. Structural parameters of the double membrane chamber membrane capacitor desalination module: the distance between the cation exchange membrane and the anion exchange membrane is 1.0mm, the mass of activated carbon fiber cloth on both sides is 2.0g; the flow rate of fresh water and concentrated water is 5mL / min, the output voltage of the DC power supply It is 1.2V; the time relay controls the polarity reversal time to be 90min.

[0026] Experimental operation results show that: current efficiency ≥ 104%, electric energy recovery rate 37%, clean water conductivity ≤ 0.1μS / cm, turbidity is not detected, the water output of the device fully meets the "water vapor quality of thermal power generation units and steam power equipment" (GB / T12145-2016) standard.

[0027] The design of the system fully takes into account the discontinuous water discharge characteristics of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com