Photothermal composite material, and preparation method and application thereof

A composite material and photothermal technology, applied in chemical instruments and methods, other chemical processes, general water supply conservation, etc., can solve problems such as inability to efficiently complete seawater desalination and purification, low photothermal conversion efficiency, etc., and achieve large-scale The effect of production, improvement of desalination efficiency and simple technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

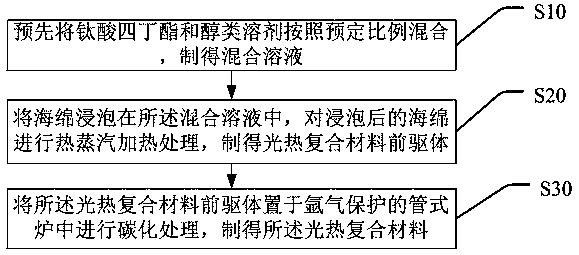

[0046] A method for preparing a photothermal composite material, comprising the following steps:

[0047] 1) Pre-mix tetrabutyl titanate and ethanol at a mass ratio of 4:1 to prepare a mixed solution;

[0048] 2) Clean the melamine nano-sponge with ethanol in advance and dry it naturally, cut the dried melamine nano-sponge into discs with a radius of 1.5 cm and a thickness of 1 cm for use; the melamine nano-sponge Soaking in the mixed solution for 10 hours, using warm water at 60°C to heat the soaked sponge with hot steam, so that the tetrabutyl titanate adsorbed in the sponge is hydrolyzed into titanium dioxide, and a photothermal composite material precursor is obtained;

[0049] 3) In an argon-protected tube furnace, the temperature was raised to 300°C at a heating rate of 5°C / min to carbonize the photothermal composite material precursor to obtain the photothermal composite material, denoted as MT -300.

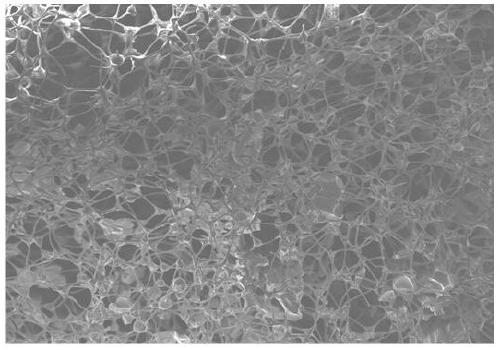

[0050] Electron microscanning is carried out to the photothermal c...

Embodiment 2

[0052] 1) Pre-mix tetrabutyl titanate and ethanol at a mass ratio of 3:1 to prepare a mixed solution;

[0053] 2) Clean the melamine nano-sponge with ethanol in advance and dry it naturally, cut the dried melamine nano-sponge into discs with a radius of 1.5 cm and a thickness of 1 cm for use; the melamine nano-sponge Soaking in the mixed solution for 10 hours, using warm water at 50°C to heat the soaked sponge with hot steam, so that the tetrabutyl titanate attached to the sponge is hydrolyzed into titanium dioxide, and a photothermal composite material precursor is obtained;

[0054] 3) In an argon-protected tube furnace, heat up to 400°C at a heating rate of 5°C / min to carbonize the precursor of the photothermal composite material to prepare the photothermal composite material, denoted as MT -400.

Embodiment 3

[0056] 1) Pre-mix tetrabutyl titanate and ethanol at a mass ratio of 3:1 to prepare a mixed solution;

[0057] 2) Clean the melamine nano-sponge with ethanol in advance and dry it naturally, cut the dried melamine nano-sponge into discs with a radius of 1.5 cm and a thickness of 1 cm for use; the melamine nano-sponge Soaking in the mixed solution for 12 hours, using warm water at 40°C to heat the soaked sponge with hot steam, so that the tetrabutyl titanate attached to the sponge is hydrolyzed into titanium dioxide, and a photothermal composite material precursor is obtained;

[0058] 3) In an argon-protected tube furnace, the temperature was raised to 500°C at a heating rate of 5°C / min to carbonize the precursor of the photothermal composite material to obtain the photothermal composite material, denoted as MT -500.

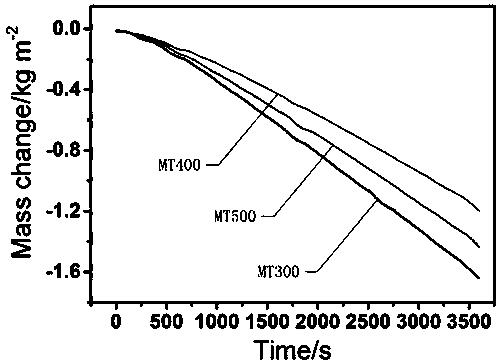

[0059] The photothermal composite material prepared in Example 1-Example 3 is used as the photothermal seawater desalination material, and the seawater is desa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com