A preparation method of a ratio oxygen sensing film for detecting dissolved oxygen content

A technology of oxygen sensing film and oxygen content, applied in measuring devices, fluorescence/phosphorescence, instruments, etc., can solve the problems of non-recoverable cost, pollution of water samples to be tested, poor resistance to photobleaching, etc., and achieve strong thermal stability and photostability, strong selectivity, and strong photobleaching resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0039] Specific Embodiment 1: The preparation method of the ratio oxygen sensing membrane used for the detection of dissolved oxygen content in this embodiment includes the following steps:

[0040] 1. Preparation of copolymer matrix material:

[0041] Mixing styrene and trifluoroethyl methacrylate to obtain a St / TFEMA mixture;

[0042] Disperse the azobisisobutyronitrile solution evenly in the St / TFEMA mixed solution, and then carry out the copolymerization reaction of the mixed solution under the protection of nitrogen. , to obtain a colorless and transparent copolymer solution;

[0043] Use methanol to wash and filter the copolymer solution several times to remove unreacted monomers, and cool it at room temperature for later use;

[0044] 2. Preparation of ratiometric oxygen sensing membrane:

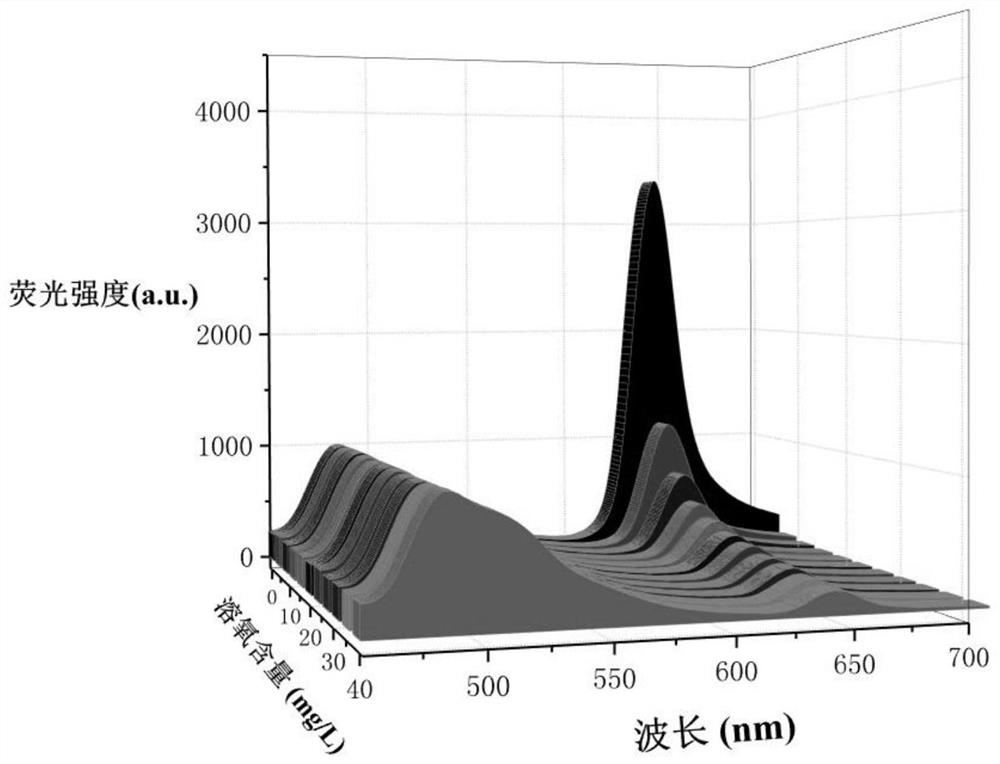

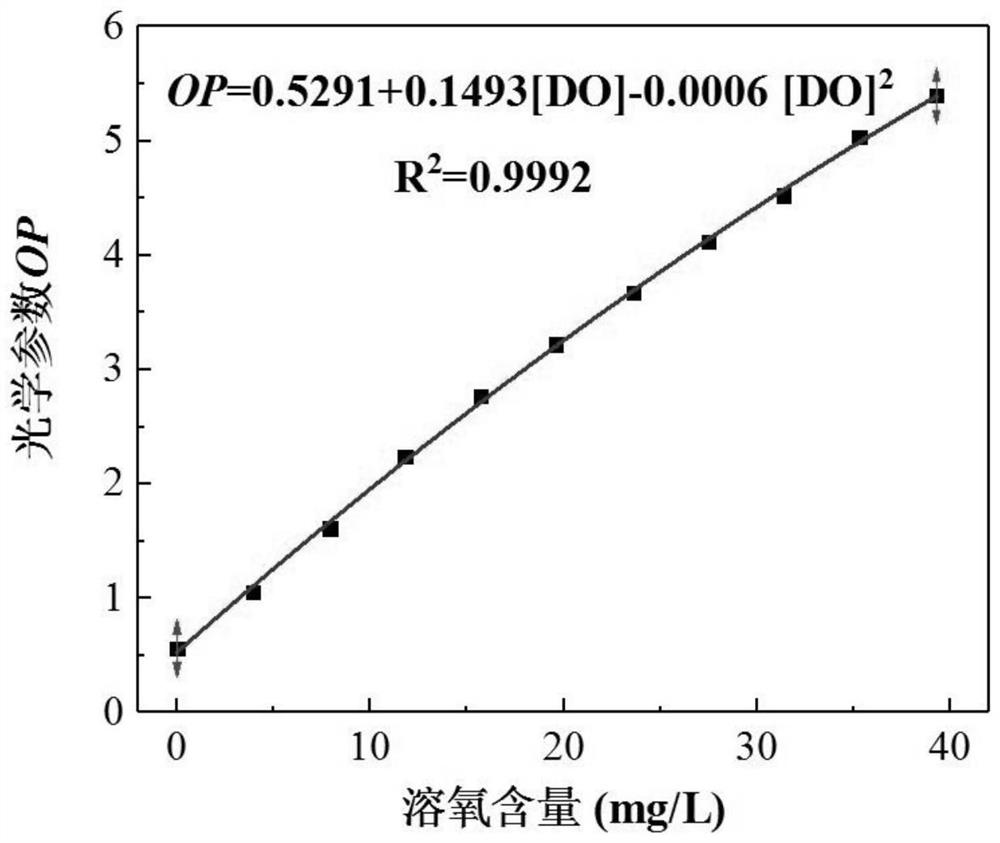

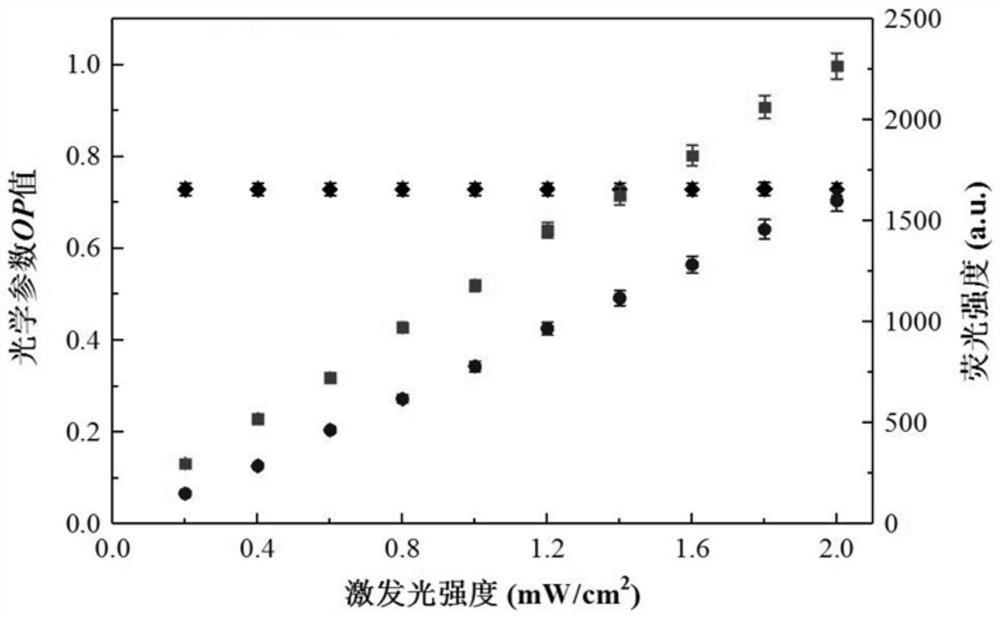

[0045] Platinum octaethylporphyrin (PtOEP) was used as an oxygen-quenching indicator, and coumarin 6 (C6) was used as a reference indicator insensitive to oxygen.

[0046] Dissolve...

specific Embodiment approach 2

[0052] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume ratio of styrene and trifluoroethyl methacrylate in Step 1 is (1-4):1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0053] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the concentration of the azobisisobutyronitrile solution in Step 1 is 0.003-0.025 g / mL. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com