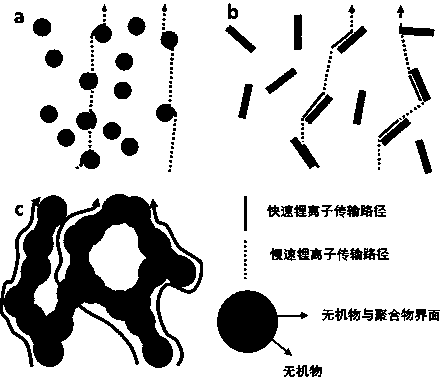

Organic-inorganic composite electrolyte with three-dimensional bicontinuous conductive phase and preparation method thereof, and application of organic-inorganic composite electrolyte with a three-dimensional bicontinuous conductive phase

An inorganic composite and conductive phase technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrolytes, etc., can solve problems such as limited conductivity and low aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]The sulfide electrolyte Li 6 P.S. 5 X (X is one or more of Cl, Br, I) and pore-forming agent P 2 S 5 According to the mass ratio of 1:1, it was accurately weighed into a mortar, and after it was ground evenly, 0.1 g was taken and placed in a ø10 mm tableting mold. The mixture was pressed into sheets with a thickness of 0.5 mm and a diameter of 10 mm under a pressure of 10 MPa. Place this slice in a quartz tube, 400 o C sintered for 8h to obtain three-dimensional porous Li 6 P.S. 5 X (X is one or more of Cl, Br, I) electrolyte sheet. Align LiTFSI and PEO according to [EO] / [Li + ] = 16 : 1 to prepare a 20 wt% acetonitrile solution, and magnetically stirred for 24 h to make the solution evenly mixed. Take the above solution and add it dropwise to the three-dimensional porous Li 6 P.S. 5 X (X is one or more of Cl, Br, I) on electrolyte sheet, 40 o C. After vacuum drying for 4 hours, repeat the above-mentioned dripping solution and drying process again until the el...

Embodiment 2

[0030] The sulfide electrolyte Li 10 m x P 3-x S 12 (0 ≤ x ≤ 2, M= Si, Ge or Sn) and pore-forming agent S according to the mass ratio of 1:1, accurately weighed into the mortar, after grinding evenly, take 0.1 g and put it into a ø10 mm tablet in the mold. The mixture was pressed into sheets with a thickness of 0.5 mm and a diameter of 10 mm under a pressure of 10 MPa. Place this slice in a quartz tube, 500 o C sintered for 10 h to obtain three-dimensional porous Li 10 m x P 3-x S 12 (0 ≤ x ≤ 2, M= Si, Ge or Sn) electrolyte sheet. LiClO 4 and PAN were configured into a 15 wt% toluene solution, and magnetically stirred for 24 h to make the solution evenly mixed. Take the above solution and add it dropwise to the three-dimensional porous Li 10 m x P 3-x S 12 (0 ≤ x ≤ 2, M= Si, Ge or Sn) on-chip electrolyte, 80 o After C vacuum drying for 4 h, repeat the above drop solution and drying process again until the electrolyte sheet no longer increases in weight. The li...

Embodiment 3

[0032] The sulfide electrolyte Li 2 S:(1-x)P 2 S 5 (x=0.7 ~ 0.8) and pore-forming agent SeS 2 According to the mass ratio of 1:1, it was accurately weighed into a mortar, and after it was ground evenly, 0.1 g was taken and placed in a ø10 mm tableting mold. The mixture was pressed into sheets with a thickness of 0.5 mm and a diameter of 10 mm under a pressure of 10 MPa. Place this slice in a quartz tube, 400 o C sintered for 8 h to obtain three-dimensional porous Li 2 S:(1-x)P 2 S 5 (x=0.7 ~ 0.8) Electrolyte sheet. LiDFOB and PVDF were prepared into 18 wt% acetonitrile solution, and stirred for 24 h to make the solution evenly mixed. Take the above solution and add it dropwise to the three-dimensional porous Li 2 S:(1-x)P 2 S 5 (x=0.7 ~ 0.8) on electrolyte sheet, 40 o After C vacuum drying for 4 h, repeat the above drop solution and drying process again until the electrolyte sheet no longer increases in weight. The lithium ion conductivity of the composite electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com