Preparation method and application of environment-friendly electro-Fenton negative electrode

A cathode and green technology, applied in the preparation method and application field of the electrode, can solve the problems of low oxygen reduction reaction activity and selectivity of the electric Fenton cathode, less accumulation, high cathode preparation cost, etc., achieving low cost and low energy consumption , The concentration range adapts to the strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

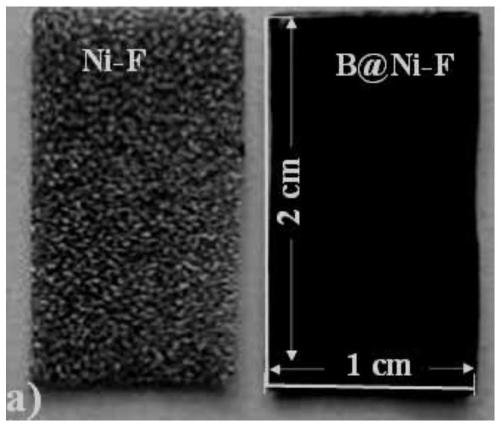

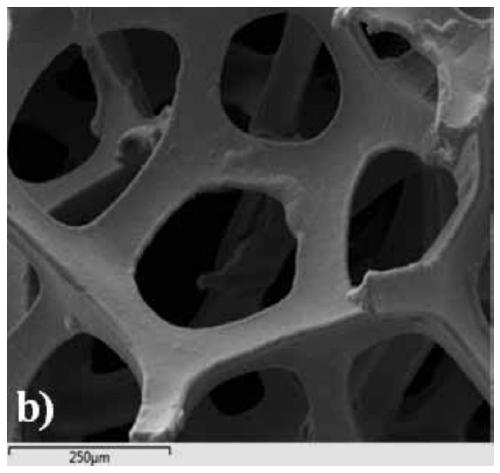

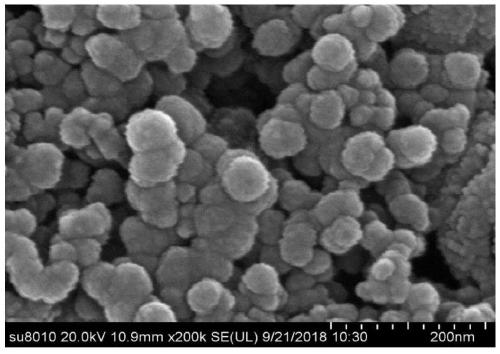

Image

Examples

specific Embodiment approach 1

[0029] Specific embodiment one: the preparation method of the green electric Fenton cathode of the present embodiment, carry out according to the following steps:

[0030] 1. Rinse the waste biomass, crush it through a 200-300 mesh sieve, and dry it to obtain biomass powder;

[0031] 2. Place the biomass powder prepared in step 1 in a quartz boat, then transfer it to a tube furnace, and feed N into the tube furnace. 2 to exclude air, and then in a nitrogen atmosphere at 5 ~ 10 ° C min -1 The heating rate is raised to 200-300°C and kept for 5-6 hours for pre-pyrolysis. After the pre-pyrolysis is completed, cool to room temperature to obtain pre-pyrolysis biomass powder;

[0032] 3. Place the pre-pyrolyzed biomass powder in step 2 in a quartz boat, then transfer it to a tube furnace, and feed N into the tube furnace. 2 to exclude air, and then in a nitrogen atmosphere at 5 ~ 10 ° C min -1 The heating rate is raised to 500-600°C and kept for 2-3 hours for pyrolysis. After the ...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment differs from Embodiment 1 in that the waste biomass described in step 1 is reed; other aspects are the same as Embodiment 1.

specific Embodiment approach 3

[0036] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the drying described in step 1 is to dry at a temperature of 50-80°C for 3-5 hours; Two same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com