Microbial activity promoter and using method thereof

A technology of microbial activity and accelerator, applied in the field of microbial activity accelerator, can solve the problems of poor mass transfer efficiency of hydrophobic substances and low biodegradation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Application of microbial activity accelerator in UASB reactor for phenol wastewater treatment.

[0022] By component: rhamnolipid 150mg / L, ZnCl 2 5mg / L, Sodium Selenite Vitamin E Injection 4mg / L, K 2 HPO 4 10.5g / L, KH 2 PO 4 4.5g / L, (NH 4 ) 2 SO 4 1.0g / L is formulated as a liquid microbial activity accelerator.

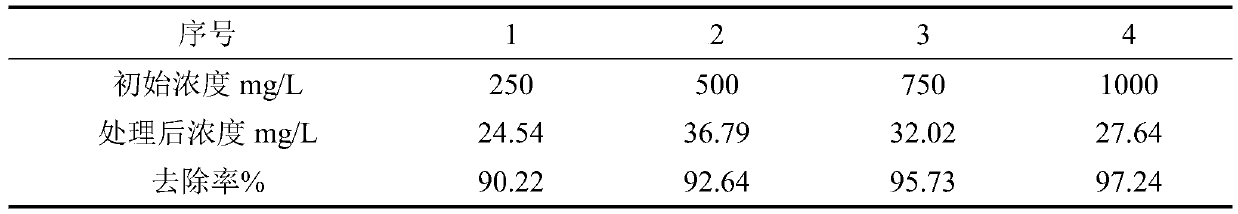

[0023] The measured phenol concentrations in four different UASB reaction pools were 250mg / L, 500mg / L, 750mg / L, and 1000mg / L, respectively. In this embodiment, the microbial activity accelerator is added to the microbial treatment unit. After calculation, the mass percentage of the microbial activity accelerator is 5% of the mass concentration of phenol.

[0024] After the UASB reaction pool was running stably, samples were taken and measured respectively. The concentrations of phenol in the four different reaction pools are shown in Table 1:

[0025] Table 1

[0026]

[0027] It can be seen from Table 1 that after adding the microbial activity acc...

Embodiment 2

[0029] The microbial activity accelerator is applied to the m-dichlorobenzene waste gas (130mg / m3) prepared by the biological trickling tower treatment laboratory 3 ).

[0030] By component: rhamnolipid 150mg / L, ZnCl 2 5mg / L, Sodium Selenite Vitamin E Injection 4mg / L, K 2 HPO 4 10.5g / L, KH 2 PO 4 4.5g / L, (NH 4 ) 2 SO 4 1.0g / L is formulated as a liquid microbial activity accelerator.

[0031] The performance of two biotrickling filter towers without and with microbial activity promoters in the treatment of m-dichlorobenzene waste gas was compared. After inoculation of m-dichlorobenzene-degrading dominant bacteria, no microbial activity accelerator was added in tower 1, and the residual gas concentration of m-dichlorobenzene was measured every 5 days. The concentration of m-dichlorobenzene in each unit time is 117.5mg / m 3 , 106.35mg / m 3 , 81.94mg / m 3 , 73.39mg / m 3 , 64.92mg / m 3 and 57.74mg / m 3 . That is, the removal rates of m-dichlorobenzene were 9.61%, 18.19%, ...

Embodiment 3

[0033] Application of microbial activity accelerator to trickling filter tower facility to treat toluene waste gas (1000mg / m 3 ).

[0034] By component: rhamnolipid 150mg / L, ZnCl 2 5mg / L, K 2 HPO 4 10.5g / L, KH 2 PO 4 4.5g / L, (NH 4 ) 2 SO 4 1.0g / L modulation microbial activity accelerator A1.

[0035] By component: rhamnolipid 150mg / L, sodium selenite vitamin E injection 4mg / L, K 2 HPO 4 10.5g / L, KH 2 PO 4 4.5g / L, (NH 4 ) 2 SO 4 1.0g / L modulation microbial activity accelerator A2.

[0036] By component: rhamnolipid 150mg / L, ZnCl 2 5mg / L, Sodium Selenite Vitamin E Injection 4mg / L, K 2 HPO 4 10.5g / L, KH 2 PO 4 4.5g / L, (NH 4 ) 2 SO 4 1.0g / L modulation microbial activity promoter A3.

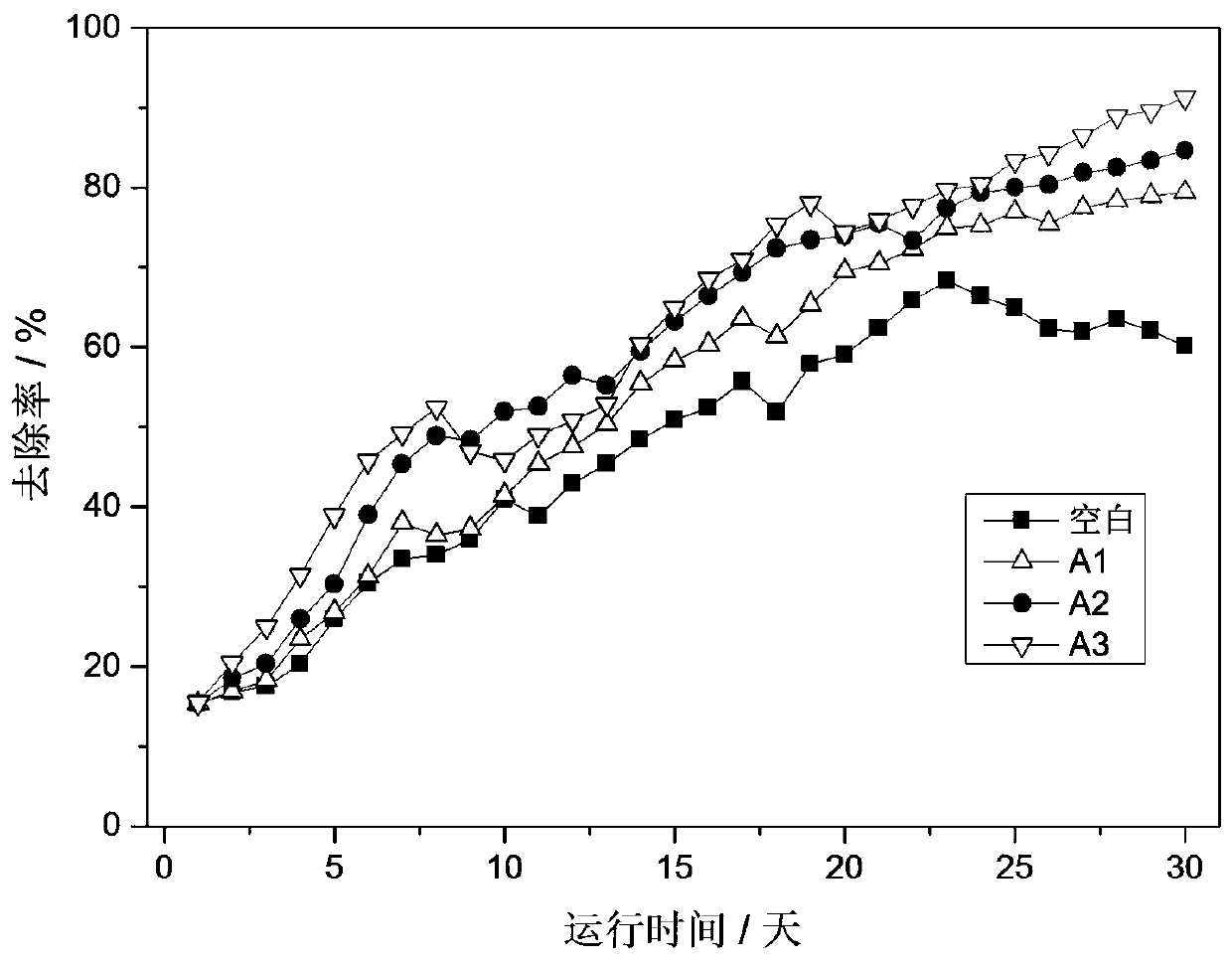

[0037] The toluene-degrading dominant bacteria were inoculated in the biotrickling filter tower, and the removal effect of toluene was compared in the four biotrickling filter towers without adding microbial activity accelerators and adding microbial activity accelerators A1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com