Supported non-metal catalyst, preparation method and application of catalyst

A non-metallic catalyst and supported technology, which is applied in the field of supported non-metallic catalysts, preparation, and catalyzed oxidative dehydrogenation of low-carbon alkanes, can solve the problem of low olefin selectivity, achieve low reaction temperature, simple preparation method, and difficult depth The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0082] Preparation of embodiment 1-1 supported non-metallic catalyst

[0083] (1) Take 467.5 mg of boric acid in a vial, add 5 mL of ethylene glycol, and stir to dissolve at 50 ° C, which is the boron precursor solution;

[0084] (2) Take 1 mL of the above solution and impregnate 1 g of SBA-15, let it stand at room temperature for 2 hours, and oven overnight at 50 ° C. The obtained sample is placed in a muffle furnace and roasted at 700 ° C for 3 hours to obtain 5% by mass B 2 o 3 / SBA-15 catalyst.

Embodiment 1-2

[0085] Preparation of embodiment 1-2 supported non-metallic catalyst

[0086] (1) Take 986.8 mg of boric acid in a vial, add 5 mL of ethylene glycol, and stir to dissolve at 50 ° C, which is the boron precursor solution;

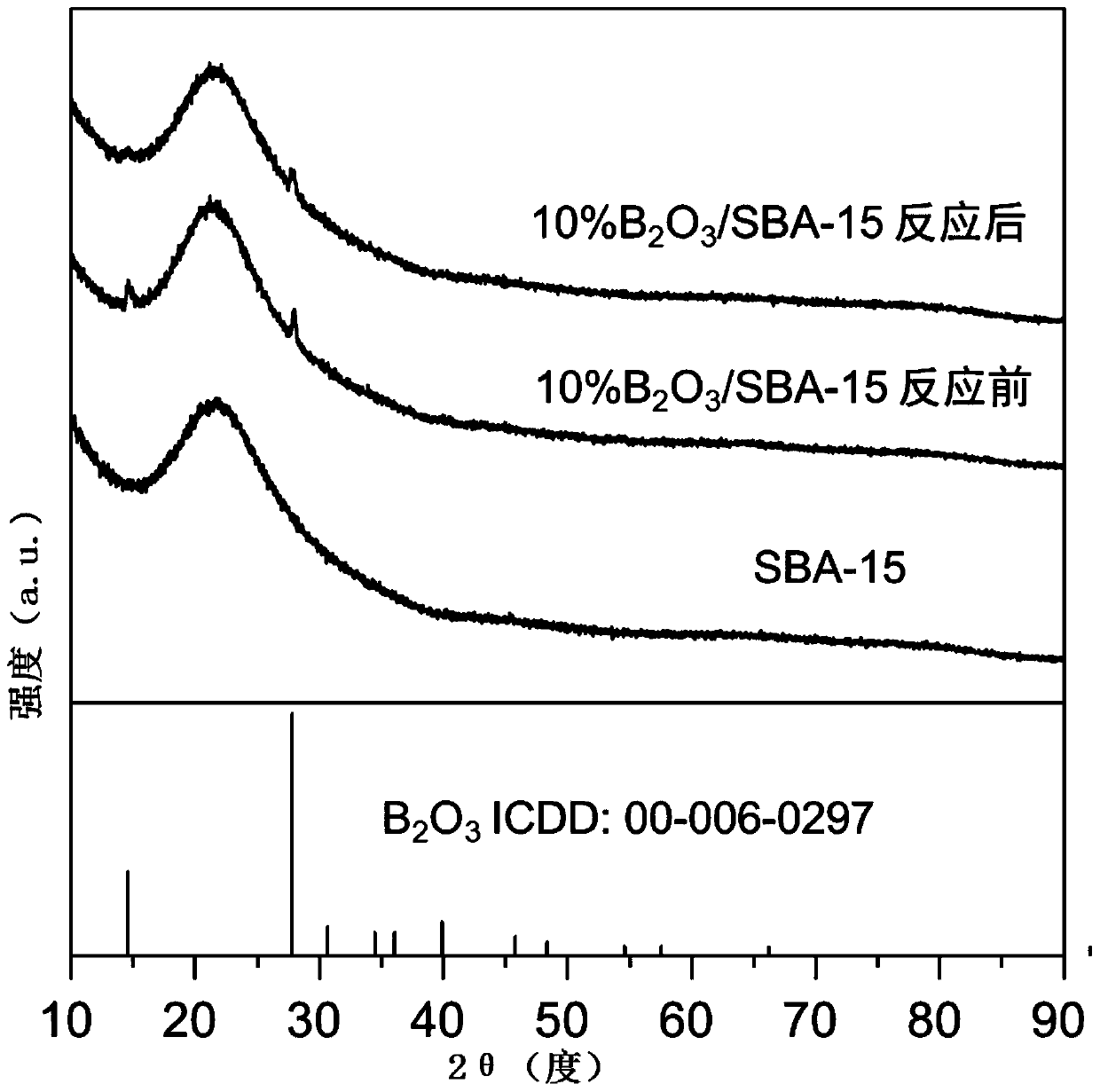

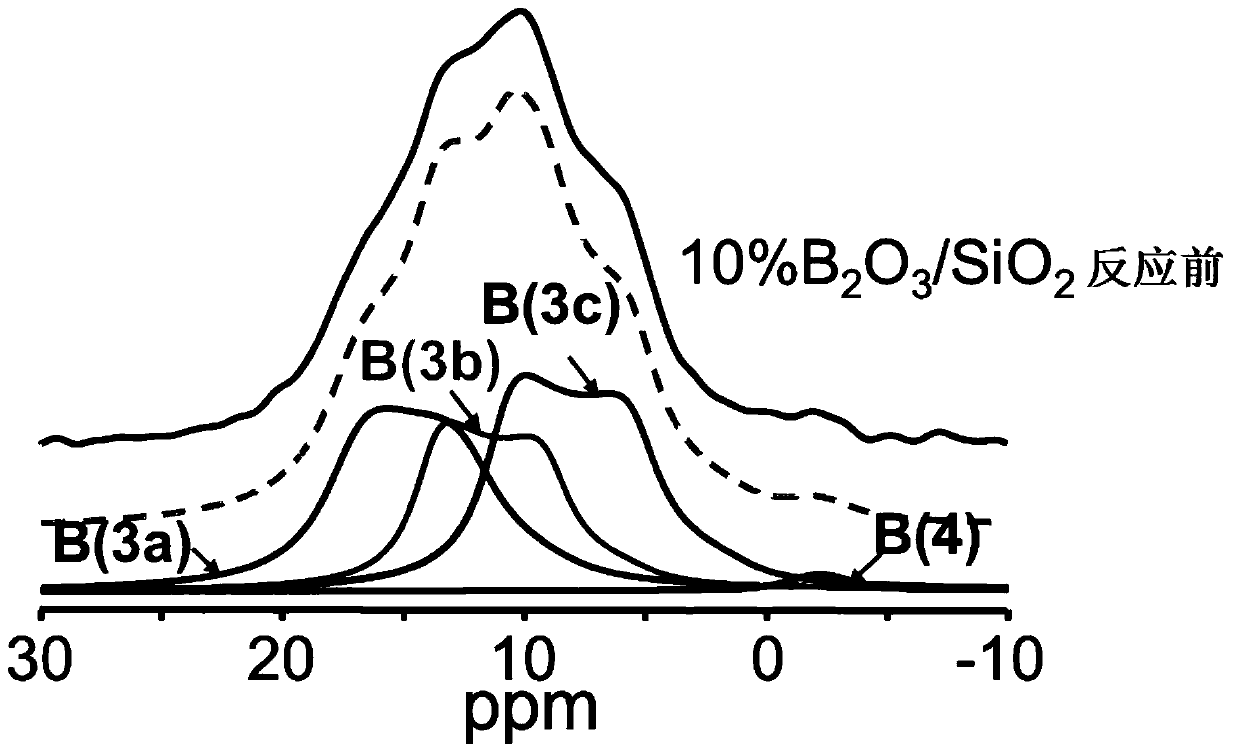

[0087] (2) Take 1 mL of the above solution and impregnate 1 g of SBA-15, let it stand at room temperature for 2 hours, and oven overnight at 50 ° C. The obtained sample is placed in a muffle furnace and roasted at 700 ° C for 3 hours to obtain 10 mass % B 2 o 3 / SBA-15 catalyst, the resulting 10% by mass B 2 o 3 The XRD pattern of / SBA-15 catalyst is as follows figure 1 As shown before the reaction, the NMR spectrum is as diagram 2-1 shown.

Embodiment 1-3

[0088] Preparation of embodiment 1-3 supported non-metallic catalyst

[0089] (1) Take 2.213g of boric acid in a vial, add 5mL of ethylene glycol, and stir to dissolve at 80°C, which is the boron precursor solution;

[0090] (2) Take 1mL of the above solution and impregnate 1g of SBA-15, let it stand at room temperature for 2h, and oven at 50°C overnight. 2 o 3 / SBA-15 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com