Nano flower-shaped ZnO photocatalyst, preparation method and application thereof

A flower-shaped zinc oxide, photocatalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., achieves good crystalline properties, uniform synthesis morphology, and preparation operations. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of nano-flower-shaped zinc oxide photocatalyst, comprising the following steps:

[0049] 1) Prepare zinc nitrate with a concentration of 0.0089g / mL in 75mL of deionized water, and add 0.315g of hexamethylenetetramine (HMTA) after it is completely dissolved to obtain a mixed solution a;

[0050] 2) Prepare a NaOH solution with a concentration of 0.024g / mL in 37.5mL deionized water, then slowly add it to the mixed solution a obtained in step 1, and stir at 550rpm for 10min to obtain the mixed solution b;

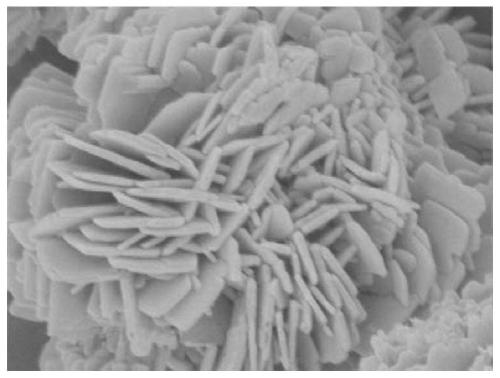

[0051] 3) Transfer the mixed solution b obtained in step 2 to a hydrothermal reaction kettle and react at 100°C for 12 hours. After the reaction, cool the product down to room temperature, centrifuge, wash with deionized water three times, and dry at room temperature for 24 hours to obtain a nanoflower Zinc oxide photocatalyst (represented by ZnO-0 below), its scanning electron microscope picture is as figure 1 As shown, the XRD pattern is as Fig...

Embodiment 2

[0055] A zinc oxide nanoflower and a preparation method thereof, comprising the following steps:

[0056] 1) Prepare zinc nitrate with a concentration of 0.0089g / mL in 75mL of deionized water, and add 0.315g of hexamethylenetetramine (HMTA) after it is completely dissolved to obtain a mixed solution a;

[0057] 2) Prepare a NaOH solution with a concentration of 0.024g / mL in 37.5mL deionized water, then slowly add it to the mixed solution a obtained in step 1, and stir at 550rpm for 10min to obtain the mixed solution b;

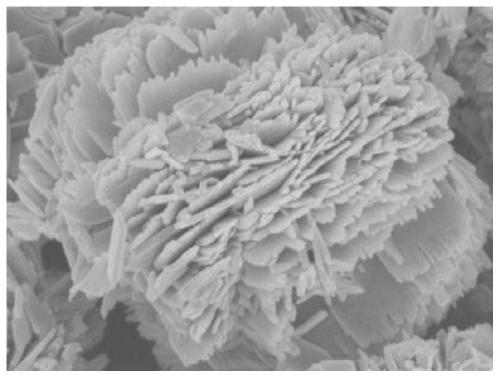

[0058] 3) Put the mixed liquid b obtained in step 2 into an ultrasonic cleaner (power 250W) for ultrasonic treatment for 60 minutes, then transfer it to a hydrothermal reaction kettle and react at 100°C for 12 hours. After the reaction, cool the product to room temperature and centrifuge. Wash three times with deionized water, dry at room temperature for 24h to obtain the nano-flower-shaped zinc oxide photocatalyst (hereinafter represented by ZnO-250), and its...

Embodiment 3

[0062] A zinc oxide nanoflower and a preparation method thereof, comprising the following steps:

[0063] 1) Prepare zinc nitrate with a concentration of 0.0089g / mL in 75mL of deionized water, and add 0.315g of hexamethylenetetramine (HMTA) after it is completely dissolved to obtain a mixed solution a;

[0064] 2) Prepare a NaOH solution with a concentration of 0.024g / mL in 37.5mL deionized water, then slowly add it to the mixed solution a obtained in step 1, and stir at 550rpm for 10min to obtain the mixed solution b;

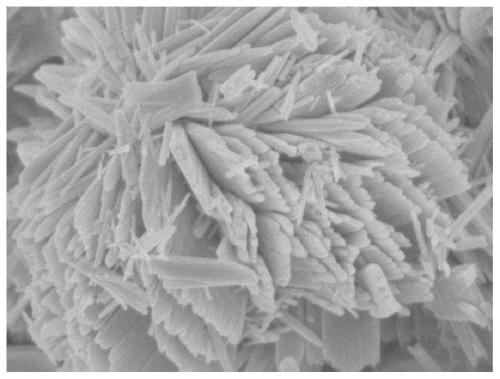

[0065] 3) Put the mixed liquid b obtained in step 2 into an ultrasonic cell disruptor (power 950W) for ultrasonic treatment for 60 minutes, then transfer to a hydrothermal reaction kettle and react at 100°C for 12 hours. After the reaction, cool the product to room temperature and centrifuge , washed three times with deionized water, and dried at room temperature for 24 hours to obtain a nano-flower-shaped zinc oxide photocatalyst (hereinafter represented by Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com