Preparation method of hydroxyapatite supported heteropolyacid salt catalyst for catalytic oxidation desulfurization

A technology for catalytic oxidative desulfurization and hydroxyapatite, which is used in the purification of oxygenated compounds, organic compounds/hydrides/coordination complex catalysts, physical/chemical process catalysts, etc., which can solve the problem of high cost and difficulty in recycling. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

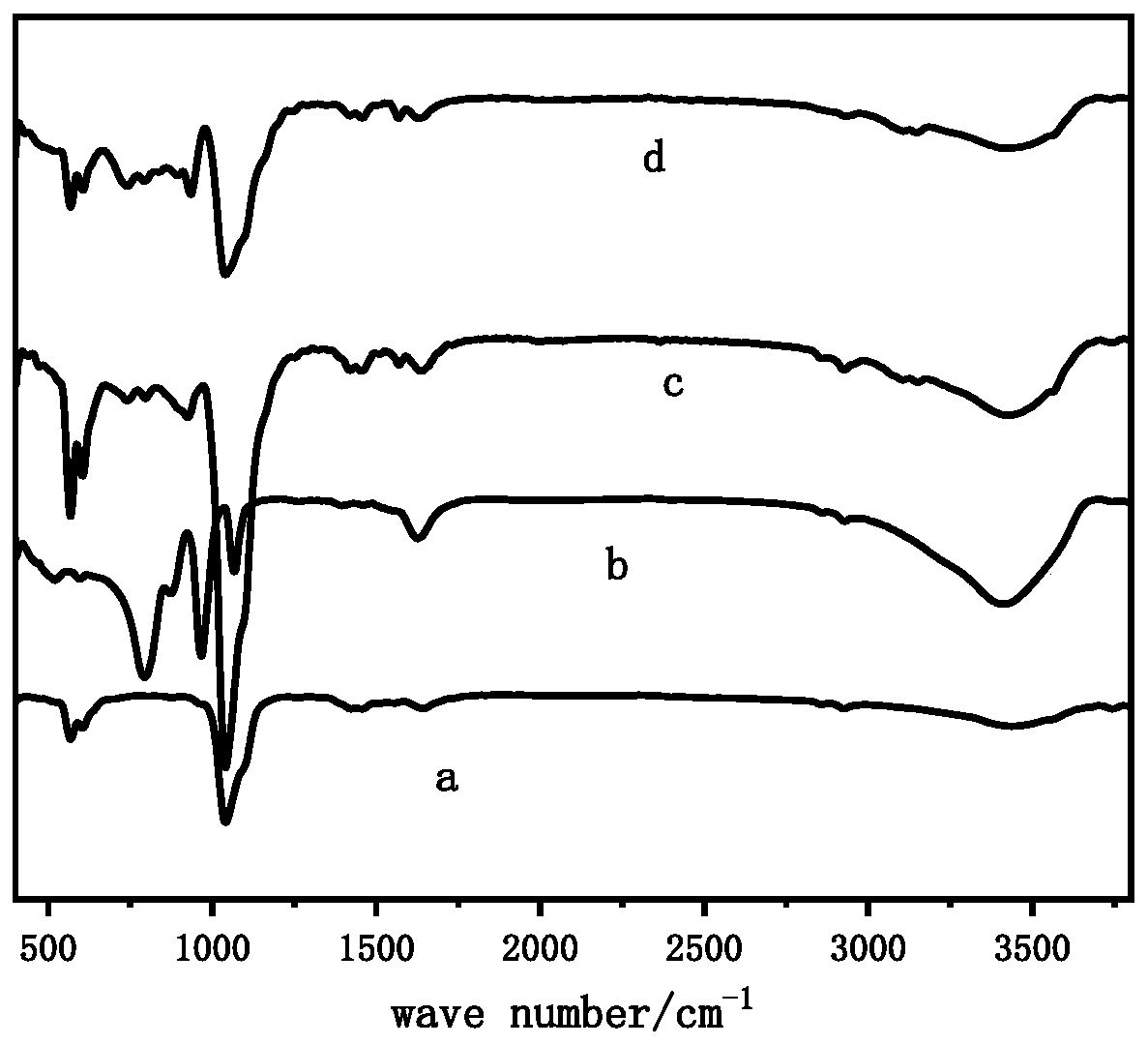

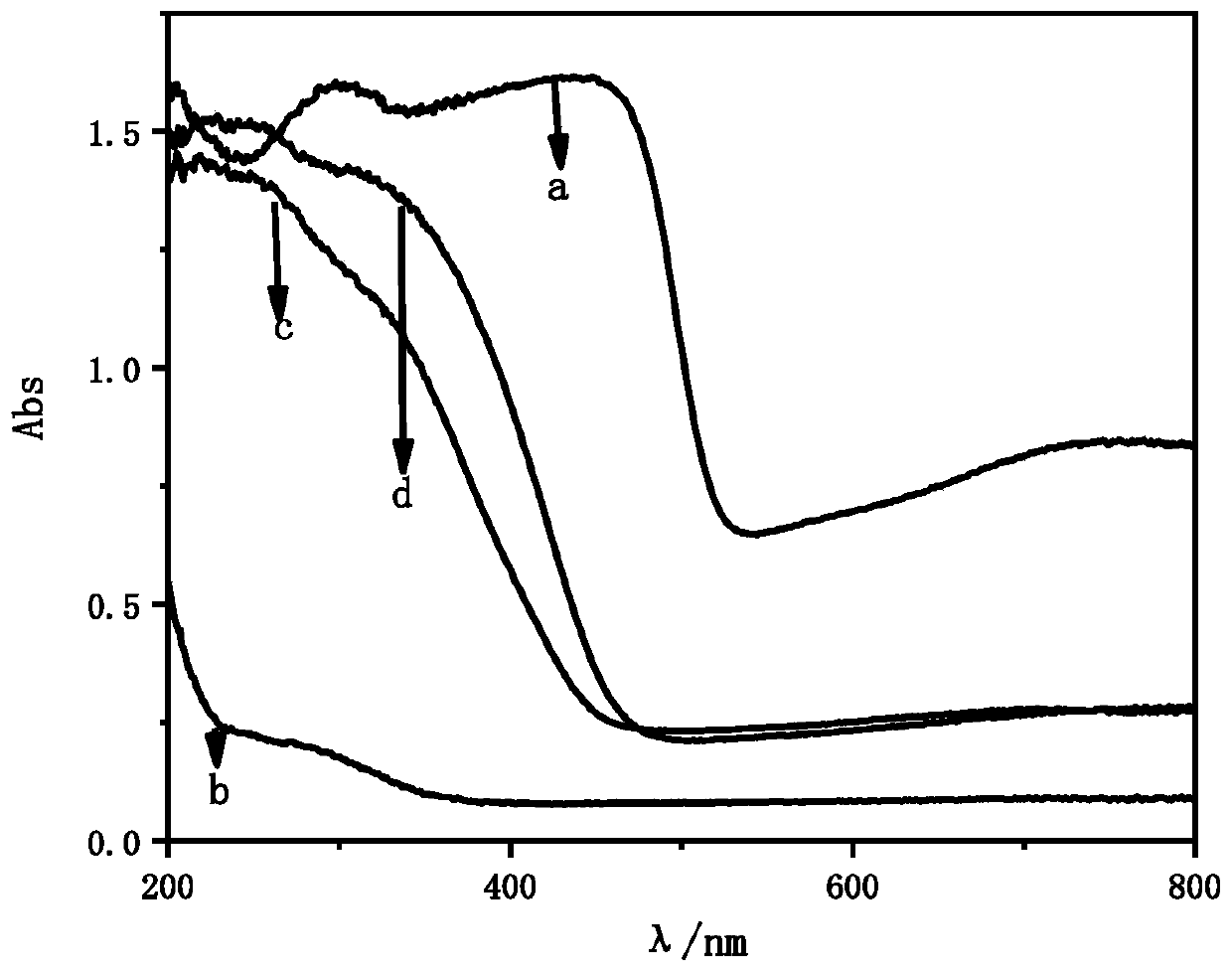

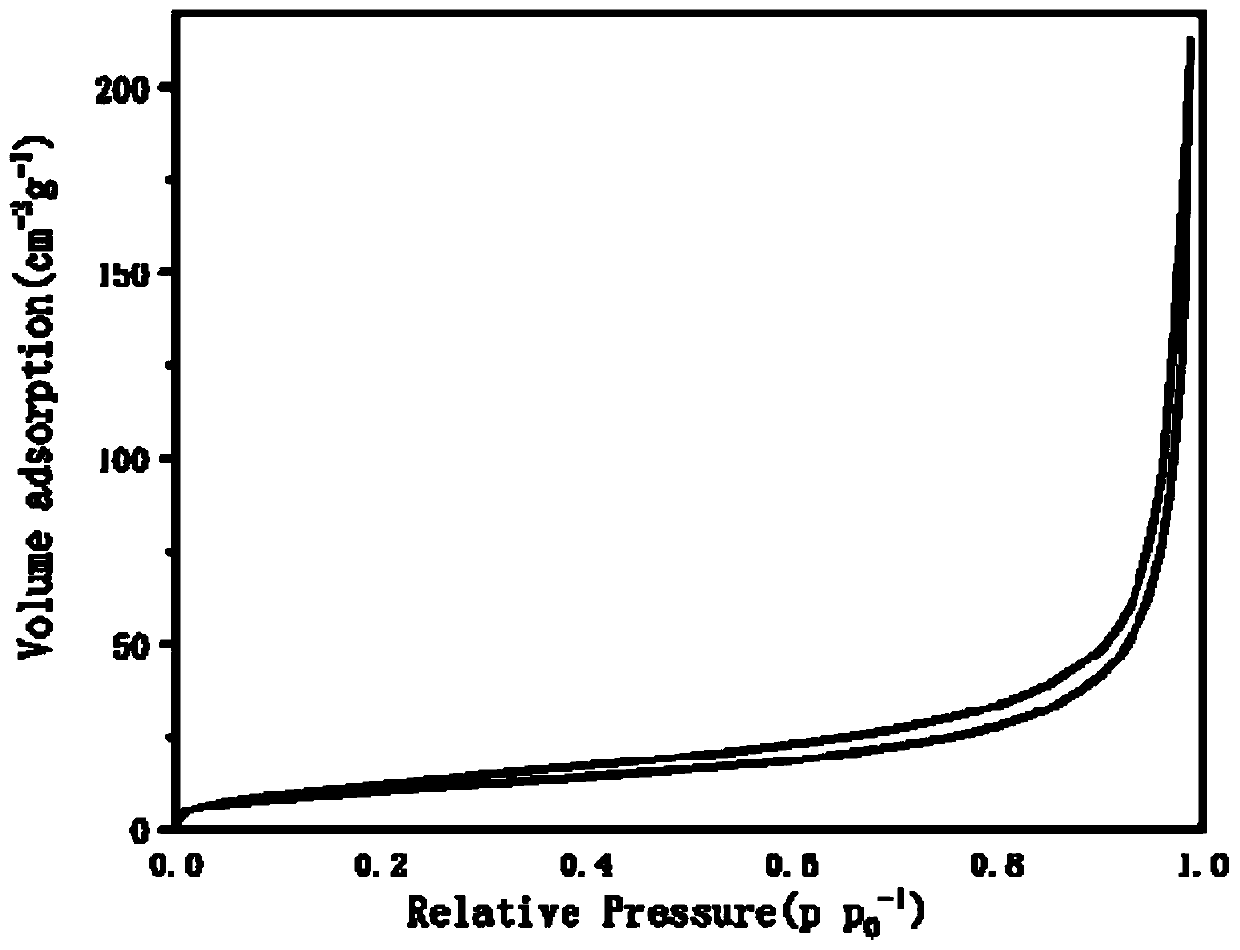

[0030] Preparation of hydroxyapatite-supported phosphotungstate catalyst:

[0031] Mix 0.5g of 3-chloropropyl-trimethoxysilane with 1g of N-methylimidazole, control the temperature at 95°C, stir vigorously for 16h, extract and separate the ionic liquid, and then mix the ionic liquid with hydroxyapatite by mass The ratio is 1:2 for feeding, reflux stirring for 15h, and drying to obtain hydroxyapatite-bonded ionic liquid. The ionic liquid (molar ratio: 20:2) bonded with phosphotungstic acid and hydroxyapatite was reacted at 35°C for 2 hours, washed and dried with a solvent to obtain a hydroxyapatite-supported phosphotungstate catalyst.

Embodiment 2

[0032] Embodiment 2: Preparation of hydroxyapatite supported phosphomolybdate catalyst:

[0033] Mix 0.3g of 3-chloropropyl-trimethoxysilane with 1g of N-methylimidazole, control the temperature at 95°C, stir vigorously for 16 hours, extract and separate the ionic liquid, and then mix the ionic liquid with hydroxyapatite in a mass ratio Feed for a ratio of 1:1.5, reflux and stir for 15 hours, and dry to obtain a hydroxyapatite-bonded ionic liquid. The ionic liquid (molar ratio: 25:1) bonded to phosphomolybdic acid and hydroxyapatite was reacted at 35° C. for 2 hours, washed and dried with a solvent to obtain a hydroxyapatite-supported phosphomolybdate catalyst.

Embodiment 3

[0034] Embodiment 3: Preparation of hydroxyapatite supported vanadium molybdate catalyst:

[0035]Mix 0.3g of 3-chloropropyl-trimethoxysilane with 1g of 1-ethylimidazole, control the temperature at 95°C, stir vigorously for 16 hours, extract and separate the ionic liquid, and then mix the ionic liquid with hydroxyapatite by mass The ratio is 1:2 for feeding, reflux stirring for 15h, and drying to obtain hydroxyapatite-bonded ionic liquid. The ionic liquid (molar ratio: 40:1) bonded with vanadium molybdenum acid and hydroxyapatite was reacted at 35° C. for 2 hours, washed and dried with a solvent to obtain a hydroxyapatite-supported vanadium molybdate catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com