A kind of production technology of by-product potassium bromide in the synthesis of propiconazole

A production process and potassium bromide technology are applied in the chemical industry, organic chemistry, alkali metal halide purification and other directions, can solve the problems of high separation and purification cost, waste of resources, difficult separation of potassium bromide, etc., and reduce the separation and purification cost. , resource saving, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

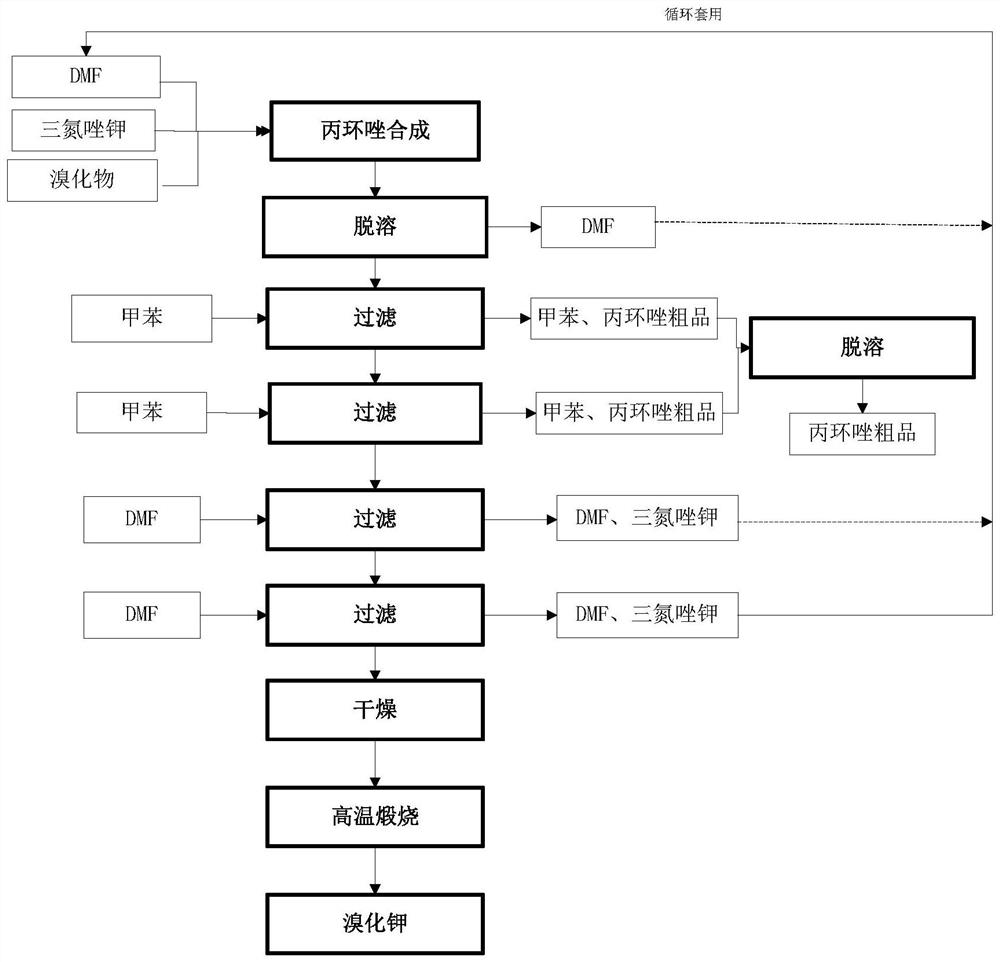

[0029] A kind of production technology of by-product potassium bromide in the synthesis of propiconazole

[0030] Proceed as follows:

[0031] Step 1. Put 425kg of potassium triazole, 1460kg of DMF, and 980kg of bromide into a 3000L kettle, raise the temperature to 135°C at a rate of 5°C / min and keep it warm for 5.5 hours. Recover DMF under pressure, and stop recovery when the temperature of the reactant drops to 135°C;

[0032] Among the above, the bromide is 2-bromomethyl-(2,4-dichlorophenyl)-4-propyl-1,3-dioxolane; the content of bromide in the reaction is 0.42%.

[0033] Step 2. After the DMF is removed, add 1160kg of toluene to the reactant, raise the temperature to 100°C, and then transfer all the materials to a three-in-one filter equipment, and use nitrogen pressure filtration, wherein the pressure is 0.5MPa, and the solid after filtration is Add 500kg of toluene again, turn on the three-in-one stirring and heating equipment, raise the temperature to 100°C, heat and ...

Embodiment 2

[0036] A kind of production technology of by-product potassium bromide in the synthesis of propiconazole

[0037] Proceed as follows:

[0038] Step 1: Put 445kg of potassium triazole, 1520kg of DMF, and 1020kg of bromide into a 3000L kettle, heat up to 155°C at a rate of 15°C / min and keep warm for 6.5 hours. Recover DMF under pressure, and stop the recovery when the temperature of the reactant drops to 140°C;

[0039] Among the above, the bromide is 2-bromomethyl-(2,4-dichlorophenyl)-4-propyl-1,3-dioxolane; the content of bromide in the reaction is 0.38%.

[0040]Step 2: After the DMF is removed, add 1240kg of toluene to the reactant, raise the temperature to 120°C, and then transfer all the materials to the three-in-one filter equipment, and use nitrogen pressure filtration, wherein the pressure is 0.8MPa, and the solid after filtration is Add 500kg of toluene again, turn on the three-in-one stirring and heating equipment, raise the temperature to 120°C, heat and stir for 8...

Embodiment 3

[0043] A kind of production technology of by-product potassium bromide in the synthesis of propiconazole

[0044] Step 1. Put 430kg of potassium triazole, 1480kg of DMF, and 990kg of bromide into a 3000L kettle, and raise the temperature to 140°C at a rate of 8°C / min and keep it warm for 6.5 hours. After the reaction is completed, under the condition of vacuum degree of -0.098MPa, Recover DMF under reduced pressure, and stop the recovery when the temperature of the reactant drops to 1360°C;

[0045] Among the above, the bromide is 2-bromomethyl-(2,4-dichlorophenyl)-4-propyl-1,3-dioxolane; the content of bromide in the reaction is 0.25%.

[0046] Step 2. After the DMF is removed, add 1180kg of toluene to the reactant, raise the temperature to 105°C, and then transfer all the materials to a three-in-one filter equipment, and use nitrogen pressure filtration, wherein the pressure is 0.6MPa, and the solid after filtration is Add 500kg of toluene again, turn on the three-in-one st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com