A kind of preparation method of deuterated alcohol compound

A compound and alcohol technology, which is applied in the field of preparation of deuterated alcohol compounds, can solve the problems of dangerous reaction process, harsh reaction conditions, and low deuterium substitution rate, and achieve the goal of reducing risk, mild reaction conditions, and simple product separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

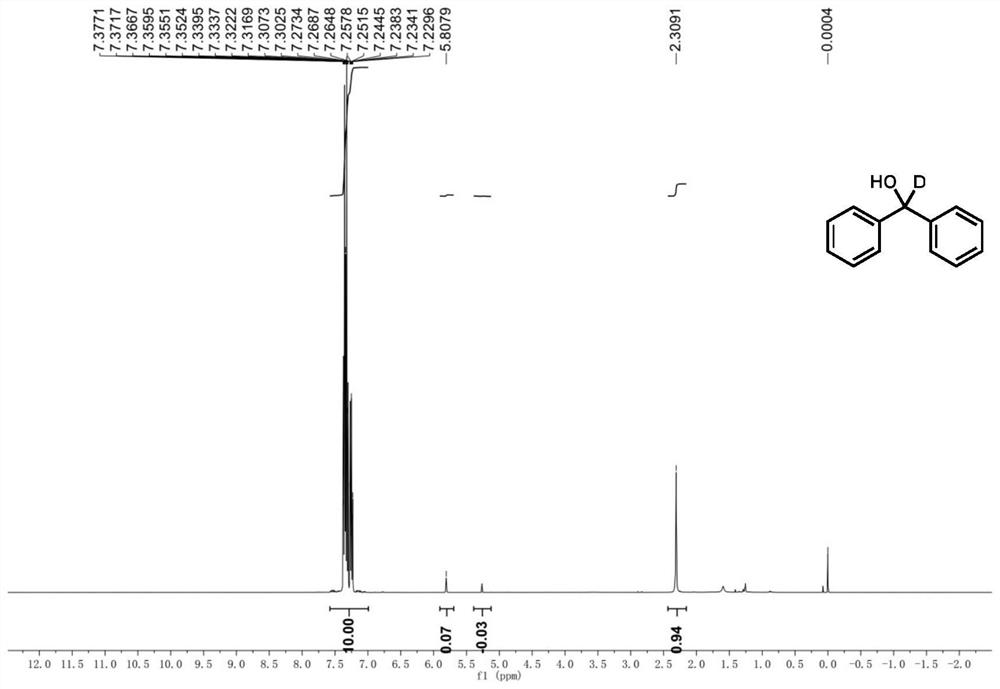

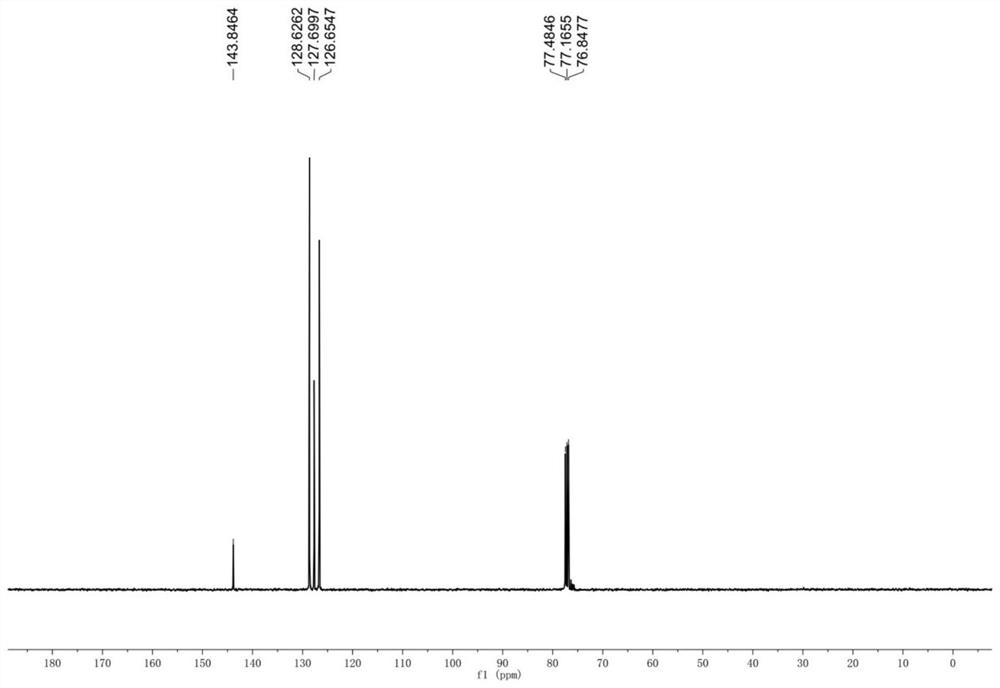

[0100] Prepare benzhydryl alcohol (2a), structural formula is as follows:

[0101]

[0102] The reaction equation is as follows:

[0103]

[0104] According to the typical experimental procedure, with benzophenone (1a) (0.0364g, 0.2mmol), catalyst Ir-9 (0.9mg, 0.5mol%), N,N-dicyclohexylmethylamine (86μL, 0.4mmol), Li 2 CO 3 (8.9mg, 0.12mmol), heavy water (36μL, 2mmol), dissolved in 3mL ultra-dry acetonitrile for reaction. After the reaction, the crude product was purified by column chromatography (eluted with PE / EA=100 / 1~50 / 1) to obtain the target product (27mg, yield: 70%, 93% deuteration rate), the product It is a white solid. 1 HNMR (400MHz, CDCl 3 ): δ7.40–7.29(m,8H), 7.29–7.25(m,2H), 2.33(s,1H). 13 CNMR (101MHz, CDCl 3 ): δ132.91–116.81(m),82.61–63.41(m).

Embodiment 2

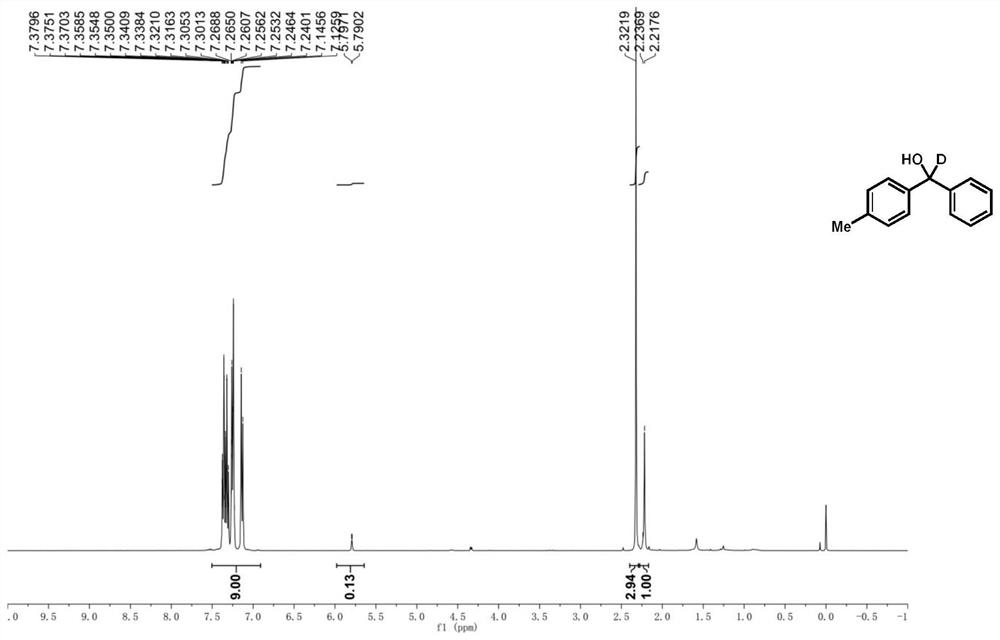

[0106] Prepare 4-methyl-benzhydryl alcohol (2b), the structural formula is as follows:

[0107]

[0108] The reaction equation is as follows:

[0109]

[0110]According to the typical experimental procedure, with 4-methyl-benzophenone (1b) (0.0398g, 0.2mmol), catalyst Ir-7 (0.9mg, 0.5mol%), N,N-dicyclohexylmethylamine (86μL , 0.4mmol), Li 2 CO 3 (8.9mg, 0.12mmol), D 2 O (36 μL, 2 mmol), dissolved in 3 mL ultra-dry acetonitrile for reaction. After the reaction, the crude product was purified by column chromatography (eluted with PE / EA=100 / 1~50 / 1) to obtain the target product (27.9 mg, yield: 70%, 87% deuteration rate), the The product is a white solid. 1 H NMR (400MHz, CDCl 3 ):δ7.56–6.75(m,9H),2.32(s,3H),2.22(s,1H). 13 C NMR (101MHz, CDCl 3 ): δ143.98, 140.99, 137.40, 129.30, 128.57, 127.57, 126.61, 126.54, 76.19, 75.98, 75.76, 75.54, 21.24.

Embodiment 3

[0112] Prepare 2-chloro-benzhydryl alcohol (2c), the structural formula is as follows:

[0113]

[0114] The reaction equation is as follows:

[0115]

[0116] According to the typical experimental procedure, with 2-chloro-benzophenone (1c) (0.0433g, 0.2mmol), catalyst Ir-5 (0.9mg, 0.5mol%), N,N-dicyclohexylmethylamine (86μL, 0.4mmol), Li 2 CO 3 (8.9mg, 0.12mmol), D 2 O (36 μL, 2 mmol), dissolved in 3 mL ultra-dry acetonitrile for reaction. After the reaction, the crude product was purified by column chromatography (eluted with PE / EA=100 / 1~50 / 1) to obtain the target product (40.7 mg, yield: 94%, 89% deuteration rate), the The product is a white solid. 1 H NMR (400MHz, CDCl 3 ):δ7.86–6.77(m,9H),2.41(s,1H). 13 C NMR (101MHz, CDCl 3 ): δ142.24, 141.05, 141.00, 132.58, 129.65, 128.89, 128.60, 128.11, 127.91, 127.24, 127.04, 127.02, 72.78, 72.63, 72.40, 72.18.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com