High temperature-resistant epoxy resin for composite material prepreg, and synthesis technology thereof

An epoxy resin and composite material technology, applied in the field of composite materials, can solve the problems of low temperature resin fluidity not as good as epoxy resin, double horse resin, long curing time, low temperature, etc., to achieve high impact toughness and short curing time , good infiltration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]45g of trisphenol-based methane triglycidyl ether, 65g of triglycidyl p-aminophenol, 35g of o-cresol novolac epoxy resin with an epoxy value of 0.45 and 30g of modified polyethersulfone were mixed and dissolved at 120°C to obtain A transparent and uniform mixture, then mix the above epoxy resin with 25g of thermoplastic polyimide resin 5218 and 50g of curing agent 4,4-diaminodiphenylsulfone in a high-speed mixer, the stirring temperature is 80°C, and the stirring speed is 3000r / min, so that the curing agent and the like are uniformly dispersed in the epoxy resin to obtain the epoxy resin composition described in the invention.

[0040] Take a small amount of Example 1 to obtain the epoxy resin composition, and use a rotational rheometer to test its rheological properties at elevated temperature. Other compositions are vacuum degassed and poured into PTFE molds. Put the mold in an oven to cure at 150°C for 1 hour, then at 180°C for 3 hours, and at 250°C for 1-3 hours. S...

Embodiment 2

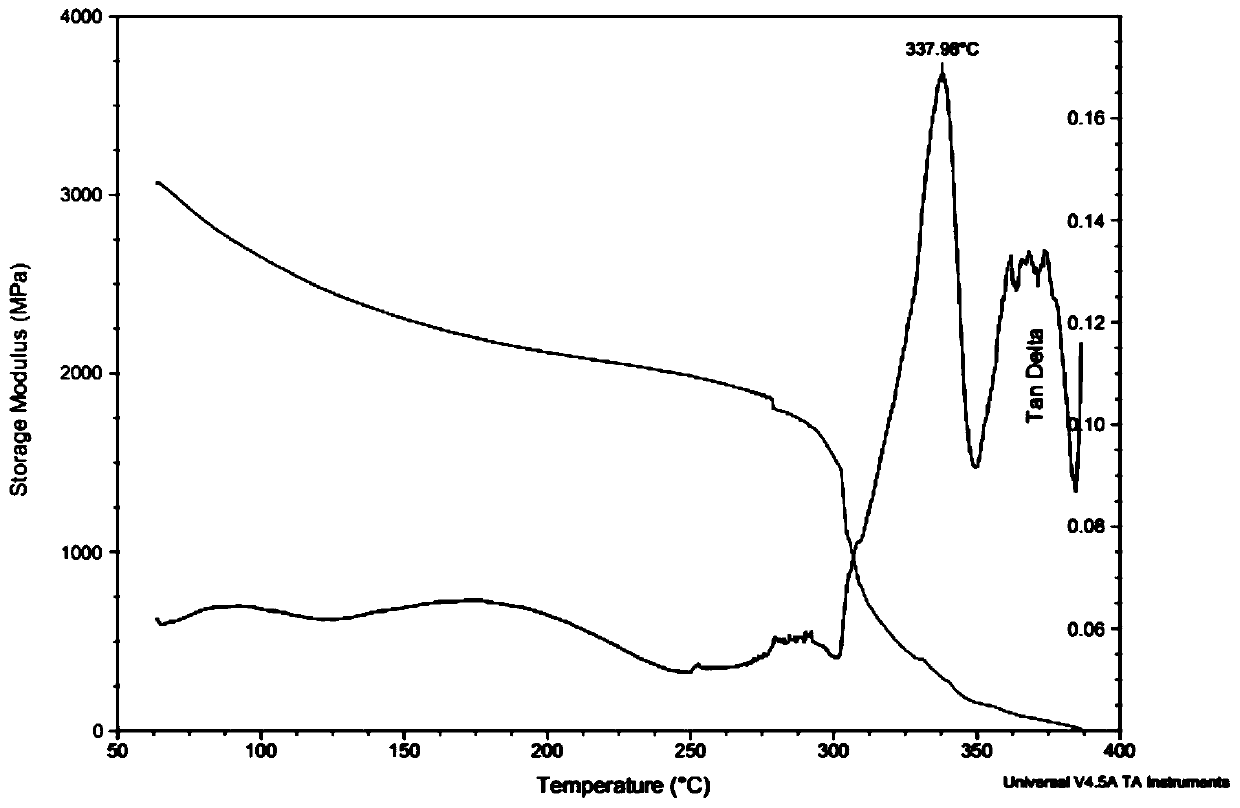

[0042] Contrast resin 6360

[0043] Mix 65g of triglycidyl p-aminophenol and 35g of o-cresol novolac epoxy resin with an epoxy value of 0.45 and stir and dissolve at 120°C to obtain a transparent and uniform mixture, then add 25g of the above epoxy resin to curing agent 4,4 - Diaminodiphenyl sulfone was stirred and mixed in a high-speed mixer, the stirring temperature was 80°C, and the stirring speed was 3000r / min, so that the curing agent and the like were uniformly dispersed in the epoxy resin, and the comparative resin 6360 was obtained. Put the mold in an oven to cure at 150°C for 1 hour, then at 180°C for 3 hours, and at 250°C for 1-3 hours.

Embodiment 3

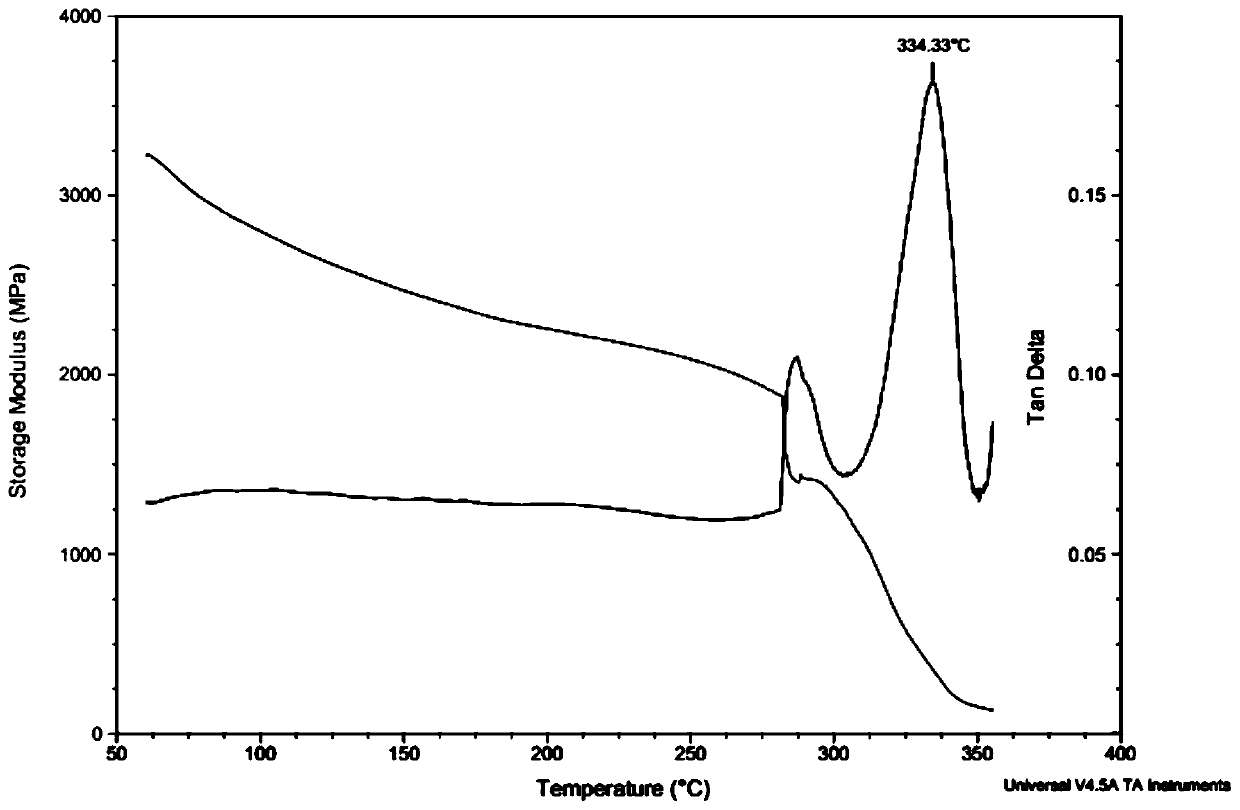

[0045] Double Horse Resin

[0046] N,N'-4,4'-diphenyl-bismaleimide 35g (component A), N,N'-2,6-toluene-bismaleimide 30g (component B) , 2,2'-diallyl bisphenol A35g (component C), thermoplastic toughening agent 20g,

[0047] Put A, B, and C into the reaction kettle, stir evenly, vacuumize and heat to 110°C, keep warm for about 10 minutes, until the three components are completely melted, then cool to 80°C, add D component to the cooled Heat the temperature to 90°C in the mixture, keep the mixture at 80°C to 90°C for 15 minutes (with vacuum), and then cool to room temperature to obtain bis-horse resin. Curing: 4 hours at 190°C, 16 hours at 230°C.

[0048] Rheological properties and performance test methods of cured products are as follows:

[0049] The rheological test adopts the Discovery HR-2 rheometer of TA Company, and tests in the air environment, the test temperature range is 60-200 degrees, the heating rate is 5 °C / min, and the shear rate is 2s-1.

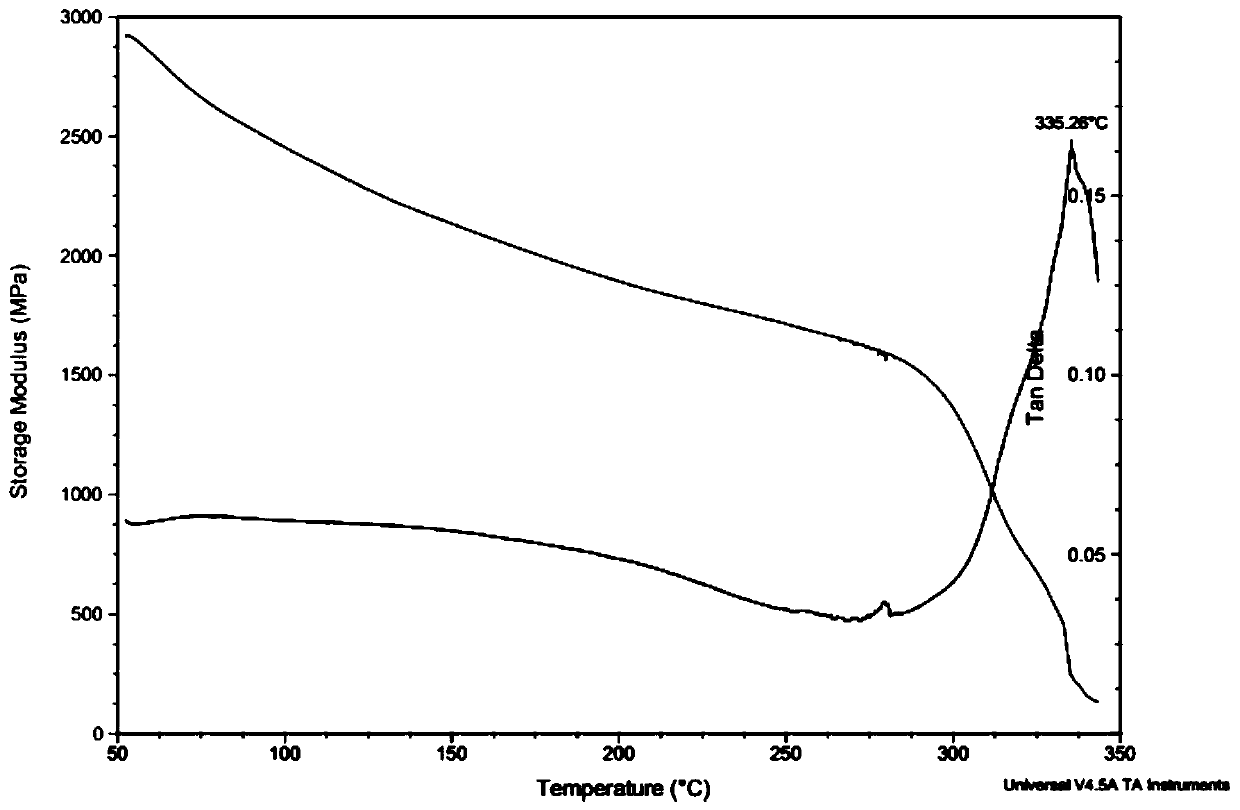

[0050] The glass t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com