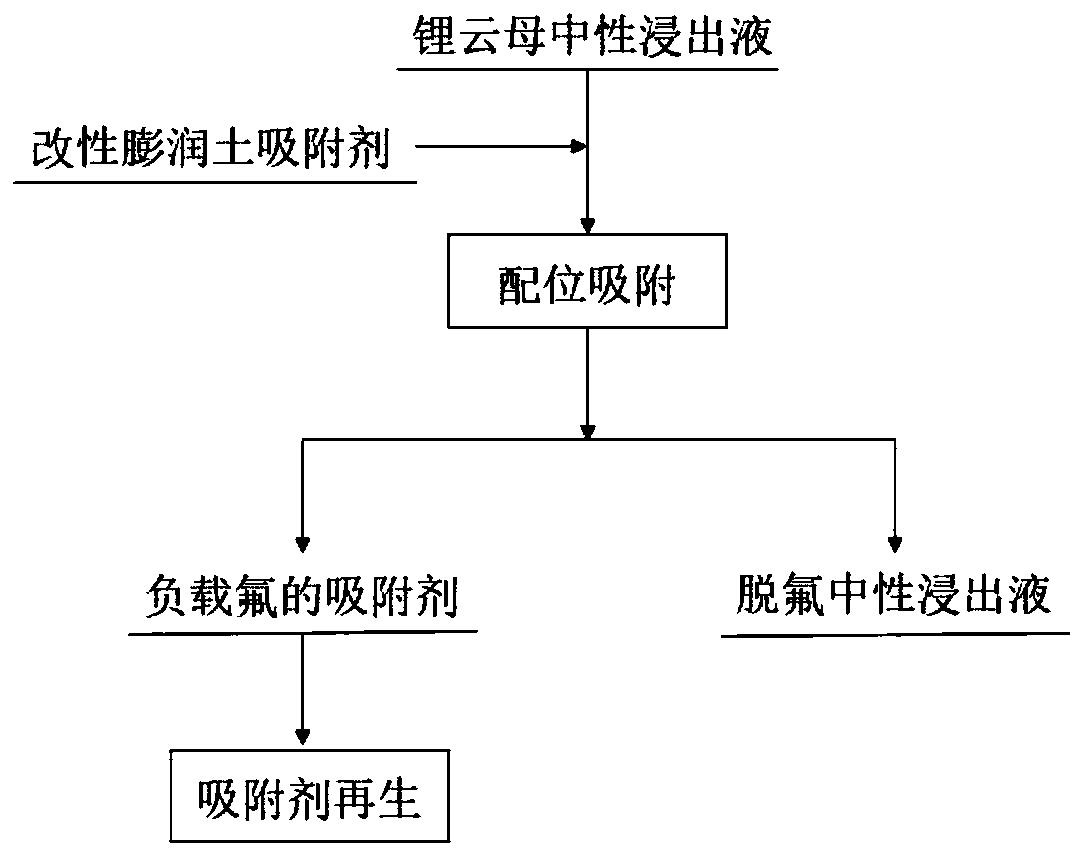

Method for removing fluorine in lepidolite ore neutral leaching solution by using modified bentonite adsorbent

A technology of bentonite and adsorbent, which is applied in the field of rare metal hydrometallurgy to achieve the effect of reducing cost, avoiding corrosion and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Accurately weigh 50g of calcium-based bentonite and place it in 100ml of 2.5mol / L H 2 SO 4 In a beaker, measure 20ml polybehenyltrimethylammonium chloride and add it into the beaker; slowly stir the obtained solution system in a constant temperature water bath at 53°C for 1h; after the stirring is completed, vacuum filter , washed with deionized water, until the pH value of the filtrate is the same as that of deionized water, and then suction filtered again; the obtained filter cake was placed in a constant temperature drying oven, and dried at a constant temperature of 120°C to activate it. After it was completely dehydrated, it was ground and passed 160 mesh sieves, obtained modified bentonite adsorbent;

[0030] (2) Get 50ml lepidolite ore neutral leach solution, record its F - The concentration is 1.06×10 -2 mol / L, adjust the pH value of the water to 7.5, add 1.5g of modified bentonite adsorbent, shake in a constant temperature water bath at 25°C for 25min, t...

Embodiment 2

[0032] (1) Accurately weigh 50g of calcium-based bentonite and place it in 100ml of 2.5mol / L H 2 SO 4 In a beaker, measure 20ml polybehenyltrimethylammonium chloride and add it into the beaker; slowly stir the obtained solution system in a constant temperature water bath at 53°C for 1h; after the stirring is completed, vacuum filter , washed with deionized water, until the pH value of the filtrate is the same as that of deionized water, and then suction filtered again; the obtained filter cake was placed in a constant temperature drying oven, and dried at a constant temperature of 120°C to activate it. After it was completely dehydrated, it was ground and passed 160 mesh sieves, obtained modified bentonite adsorbent;

[0033] (2) Get 50ml lepidolite ore neutral leach solution, record its F - The concentration is 1.06×10 -2 mol / L, adjust the pH value of the water to 8.5, add 1.5g of modified bentonite adsorbent, shake in a constant temperature water bath at 25°C for 25min, t...

Embodiment 3

[0035] (1) Accurately weigh 50g of calcium-based bentonite and place it in 100ml of 2.5mol / L H 2 SO 4 In a beaker, measure 20ml polybehenyltrimethylammonium chloride and add it into the beaker; slowly stir the obtained solution system in a constant temperature water bath at 53°C for 1h; after the stirring is completed, vacuum filter , washed with deionized water until the pH value of the filtrate is the same as that of deionized water, and then suction filtered again; the obtained filter cake was placed in a constant temperature drying oven, and dried at a constant temperature of 120°C to activate it. After it was completely dehydrated, it was ground and passed 160 mesh sieves, obtained modified bentonite adsorbent;

[0036] (2) Get 50ml lepidolite ore neutral leach solution, record its F - The concentration is 1.06×10 -2 mol / L, adjust the pH value of the water to 8.5, add 2g of modified bentonite adsorbent, shake in a constant temperature water bath at 25°C for 25min, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com