Preparation method of chitosan-pullulan electrostatic spinning composite nanofiber membrane

A technology of composite nanofibers and pullulan, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of low spinnability of chitosan, hindering fiber formation, and limiting the application of chitosan nanofibers, etc. Achieve the effect of improving spinnability, avoiding the use of toxic reagents, and improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

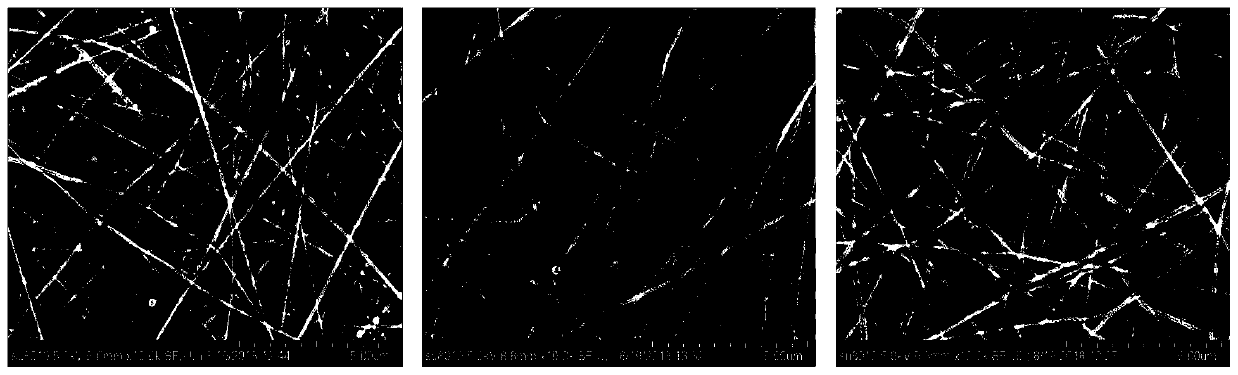

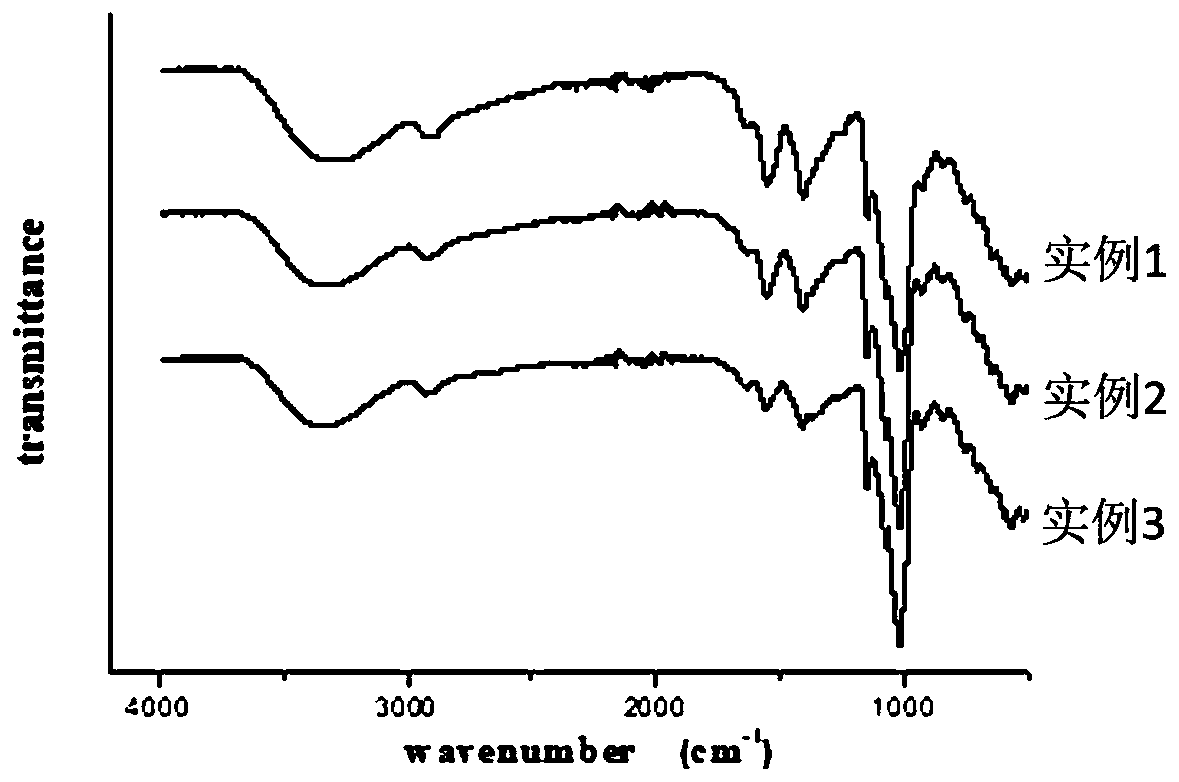

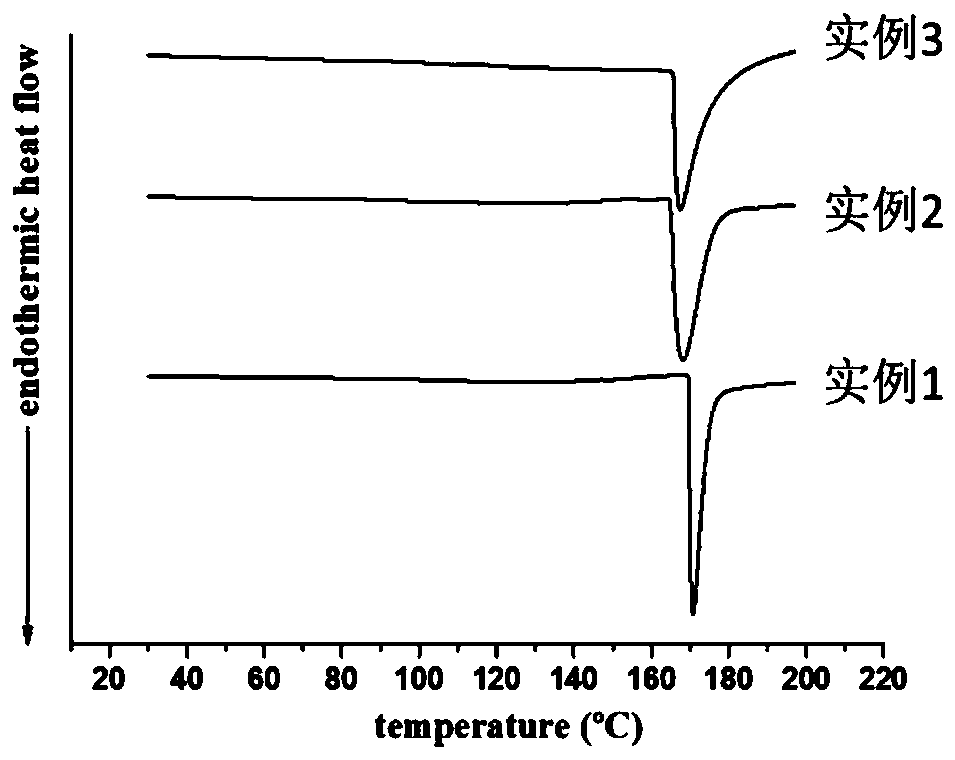

Embodiment 1

[0030] (1) Weigh 4 g of chitosan with a molecular weight of 400,000 in 80 ml of 50% acetic acid aqueous solution, and magnetically stir for 8 hours to obtain a uniform and stable transparent solution.

[0031] (2) Weigh 6 g of pullulan with a molecular weight of 200,000 in 20 ml of 50% acetic acid aqueous solution, and stir magnetically for 6 hours to obtain a stable transparent solution.

[0032] (3) Mix the solutions obtained in steps (1) and (2), and magnetically stir for 4 hours to obtain a uniform and stable transparent solution. This solution total polymer mass fraction is 10%, and the ratio of chitosan and pullulan is 40:60, and the concentration of chitosan this moment is the maximum ratio of preparation chitosan solution, exceeds this ratio, and solution is transformed into gel.

[0033] (4) Inhale the solution obtained in step (3) into a 10ml syringe, install a needle with a diameter of 0.8mm, control the flow rate at 0.5ml / h, adjust the distance from the needle to ...

Embodiment 2

[0035] (1) Weigh 3 g of chitosan with a molecular weight of 400,000 in 60 ml of 50% acetic acid aqueous solution, and magnetically stir for 8 hours to obtain a uniform and stable transparent solution.

[0036] (2) Weigh 7 g of pullulan with a molecular weight of 200,000 into 40 ml of 50% acetic acid aqueous solution, and stir magnetically for 6 hours to obtain a stable transparent solution.

[0037] (3) Mix the solutions obtained in steps (1) and (2), and magnetically stir for 4 hours to obtain a uniform and stable transparent solution. The total polymer mass fraction of the solution is 10%, and the ratio of chitosan to pullulan is 30:70.

[0038] (4) Inhale the solution obtained in step (3) into a 10ml syringe, install a needle with a diameter of 0.8mm, control the flow rate at 0.5ml / h, adjust the distance from the needle to the receiver to be 10cm, and set the voltage to 15kv. Spinning under normal pressure for 5 hours, and then drying at room temperature for 3 hours to obt...

Embodiment 3

[0040] (1) Weigh 2 g of chitosan with a molecular weight of 400,000 in 55 ml of 50% acetic acid aqueous solution, and magnetically stir for 8 hours to obtain a uniform and stable transparent solution.

[0041] (2) Weigh 8 g of pullulan with a molecular weight of 200,000 in 45 ml of 50% acetic acid aqueous solution, and stir magnetically for 6 hours to obtain a stable transparent solution.

[0042] (3) Mix the solutions obtained in steps (1) and (2), and magnetically stir for 4 hours to obtain a uniform and stable transparent solution. The total polymer mass fraction of the solution is 10%, and the ratio of chitosan to pullulan is 20:80.

[0043] (4) Inhale the solution obtained in step (3) into a 10ml syringe, install a needle with a diameter of 0.8mm, control the flow rate at 0.5ml / h, adjust the distance from the needle to the receiver to be 10cm, and set the voltage to 15kv. Spinning under normal pressure for 5 hours, and then drying at room temperature for 3 hours to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com