Method for improving dyeing performance of flax short fiber

A dyeing performance, short fiber technology, applied in the textile field, to achieve the effect of increasing softness and extensibility, improving operability, and smooth processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

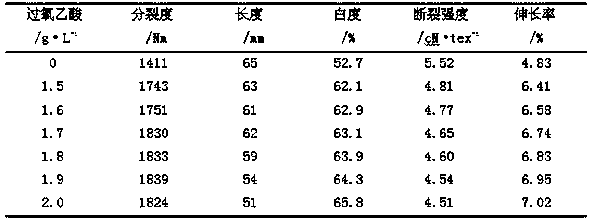

[0026] With flax short fiber as raw material, the specific process is as follows:

[0027] (1) Impregnation with penetrant JFC solution: JFC 1.5 g / L, temperature 50°C, time 40 min, liquor ratio 1:30;

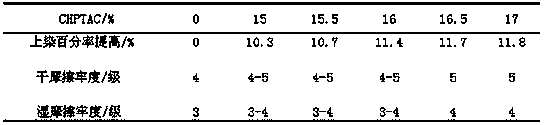

[0028] (2) Cationic modification treatment: CHPTAC 15%, sodium carbonate 6%, liquor ratio 1:30, temperature 65°C, time 50min;

[0029] (3) Warm water washing: temperature 40-50°C;

[0030] (4) Peracetic acid neutralization: peracetic acid 1.5 g / L, temperature 70°C, time 40 min, bath ratio 1:30;

[0031] (5) Warm water washing: temperature 40-50°C;

[0032] (6) Reactive dye dyeing: K-type reactive dye 0.8%, dyeing at 60°C, add sodium chloride 8.0g / L, heat up to 90°C at 1°C / min, add sodium carbonate 3.0g / L, keep warm for 50min, bath Ratio 1:30;

[0033] (7) Washing in cold water: 20-30°C;

[0034] (8) Soap boiling: soap flakes 2.0g / L, temperature 95℃, time 7min, liquor ratio 1:30;

[0035] (9) Washing in cold water: 20-30°C;

[0036] (10) Dehydration: 3 to 5 minutes;

[00...

Embodiment 2

[0039] With flax short fiber as raw material, the specific process is as follows:

[0040] (1) Impregnation with penetrant JFC solution: JFC 1.8 g / L, temperature 50°C, time 35 min, bath ratio 1:30;

[0041] (2) Cationic modification treatment: CHPTAC 16%, sodium carbonate 6%, liquor ratio 1:30, temperature 60°C, time 50min;

[0042] (3) Warm water washing: temperature 40-50°C;

[0043] (4) Peracetic acid neutralization: peracetic acid 1.6 g / L, temperature 70°C, time 45 min, bath ratio 1:30;

[0044] (5) Warm water washing: temperature 40-50°C;

[0045] (6) Reactive dye dyeing: K-type reactive dye 0.8%, dyeing at 60°C, add sodium chloride 10.0g / L, heat up to 85°C at 1°C / min, add sodium carbonate 4.0g / L, keep warm for 50min, bath Ratio 1:30;

[0046] (7) Washing in cold water: 20-30°C;

[0047] (8) Soap boiling: soap flakes 2.0g / L, temperature 95℃, time 7min, liquor ratio 1:30;

[0048] (9) Washing in cold water: 20-30°C;

[0049] (10) Dehydration: 3 to 5 minutes;

[0050]...

Embodiment 3

[0052] With flax short fiber as raw material, the specific process is as follows:

[0053] (1) Impregnation with penetrant JFC solution: JFC 2.0 g / L, temperature 40°C, time 40 min, liquor ratio 1:30;

[0054] (2) Cationic modification treatment: CHPTAC 17%, sodium carbonate 7%, liquor ratio 1:30, temperature 65°C, time 45min;

[0055] (3) Warm water washing: temperature 40-50°C;

[0056] (4) Peracetic acid neutralization: peracetic acid 1.8 g / L, temperature 75°C, time 45 min, bath ratio 1:30;

[0057] (5) Warm water washing: temperature 40-50°C;

[0058] (6) Reactive dye dyeing: K-type reactive dye 0.9%, dyeing at 60°C, add 8.5g / L sodium chloride, heat up to 85°C at 1°C / min, add 5.0g / L sodium carbonate, keep warm for 55min, bath Ratio 1:30;

[0059] (7) Washing in cold water: 20-30°C;

[0060] (8) Soap boiling: soap flakes 2.0g / L, temperature 95℃, time 7min, liquor ratio 1:30;

[0061] (9) Washing in cold water: 20-30°C;

[0062] (10) Dehydration: 3 to 5 minutes;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com