Method for preparing silicon negative electrode material containing surface modification film

A technology of surface modification and silicon negative electrode, which is applied in the field of preparation of silicon negative electrode materials, can solve the problems of unstable cycle performance of high specific energy silicon carbon negative electrodes, unsuitable binders, etc., to improve long-term cycle stability and simplify the preparation method Convenience and the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

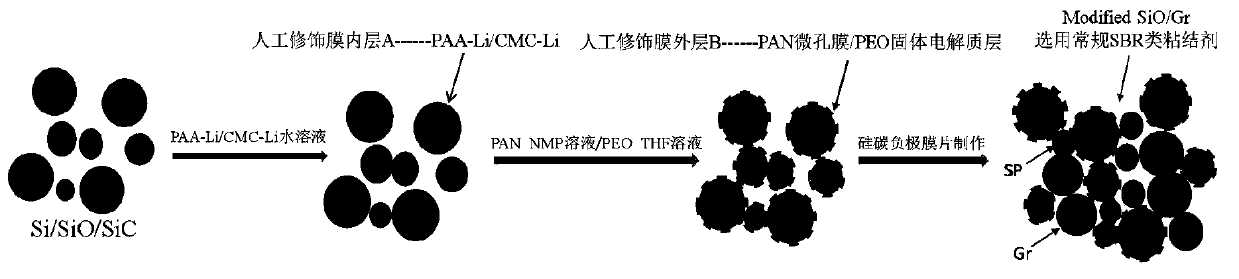

[0026] Specific implementation mode 1: This implementation mode records a method for preparing a silicon negative electrode material containing a surface modification film, and the steps of the method are as follows:

[0027] Step 1: Dissolve the polymer in water, the mass fraction of the polymer is 0.1%-100%, then add silicon material, stir while heating at a temperature of 40-80°C, remove the water in the solution, or use the spray drying method, Removing moisture to obtain a silicon material coated with a polymer film A of nanoscale thickness; the polymer is one or more of polyacrylate, carboxymethyl cellulose and alginate;

[0028]Step 2: Dissolve PAN (polyacrylonitrile) in NMP (N-methylpyrrolidone) solvent, stir to dissolve it completely, and prepare a PAN solution with a mass fraction of 0.1% to 100%; The silicon material with the polymer film A and the conductive agent are added to the PAN solution, heated and stirred at a temperature of 40-120°C to remove the NMP solve...

specific Embodiment approach 2

[0029] Specific embodiment two: the preparation method of a silicon negative electrode material containing a surface modification film described in specific embodiment one, in step one, the polyacrylate is one of polyacrylic acid, lithium polyacrylate or sodium polyacrylate The carboxymethyl cellulose salt is sodium carboxymethyl cellulose or lithium carboxymethyl cellulose; the alginate is sodium alginate or lithium alginate.

specific Embodiment approach 3

[0030] Specific embodiment three: the preparation method of a silicon negative electrode material containing a surface modification film described in specific embodiment one, in step one, the mass fraction of the polymer / silicon material is 2.0% to 100%; the silicon The material is nano-silicon, silicon carbide or silicon oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com