Integrally formed stainless steel cable bridge and preparation method thereof

A cable tray and stainless steel technology, which is applied in the field of integrated stainless steel cable tray and its preparation, can solve the problems of economical waste, information transmission safety, inability to ensure compactness, low strength and toughness, etc., to reduce the risk of open flame burning, fast and effective The effect of preparation and simplification steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

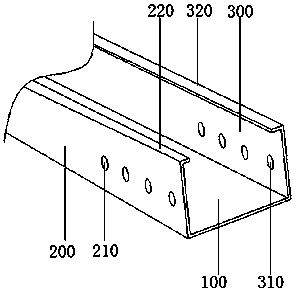

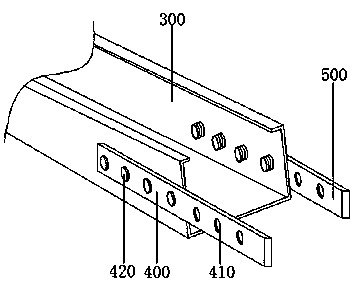

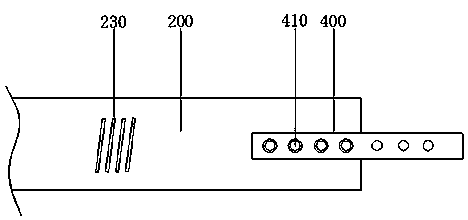

[0026] The invention provides an integrally formed stainless steel cable tray and its preparation method, which can increase the processing speed, increase the strength and toughness, and have flame retardancy. Please refer to Figure 1-6 , including a bottom plate 100, a left flap 200, a right flap 300, a left mounting plate 400 and a right mounting plate 500;

[0027] see again Figure 5 , the interior of the bottom plate 100 has a top backing plate 110, specifically, the bottom of the top backing plate 110 is bonded with a compression plate 111, the bottom of the compression plate 111 is bonded with a bottom backing plate 112, and the material of the compression plate 111 is expanded graphite powder;

[0028] see again Figure 1-3 , the bottom of the left flap 200 and the left side wall of the bottom plate 100 are fixedly installed. Specifically, the left side wall of the bottom plate 100 is integrally formed to connect with the left flap 200, and the top of the left flap ...

Embodiment

[0043] Now a kind of integrated stainless steel cable tray made by the present invention is tested and compared with a common product in the market. The test process is as follows;

[0044] 1. To process two different cable trays, process three groups respectively. It is necessary to ensure that the processing is complete without looseness, and compare the processing speed.

[0045] 2. Cooperate with a modulus of rupture device such as a modulus of rupture tester, squeeze the upper and lower ends of the embodiment to the member at the same time, measure how much MPA will be broken under high pressure strength, and then get how much MPA it can withstand.

[0046] 3. Use a combustion furnace to select different cable trays, put them into the furnace, use an open flame to continuously burn the cable trays, and observe the internal cables after 30 minutes.

[0047] The test data is as follows:

[0048] Processing speed / min Modulus of rupture / MPA Flame retardancy / %...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com