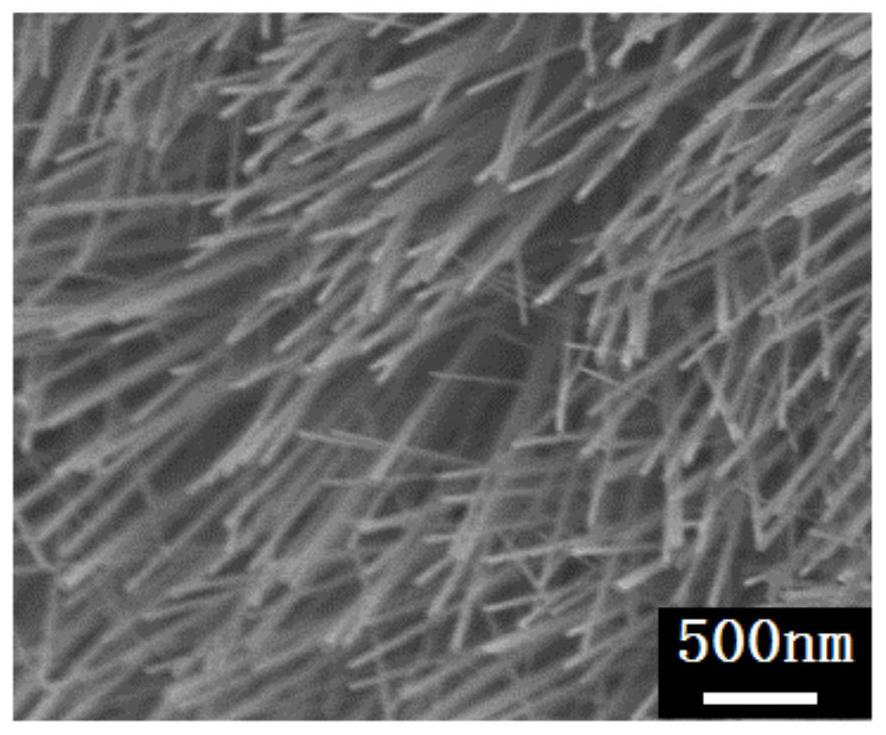

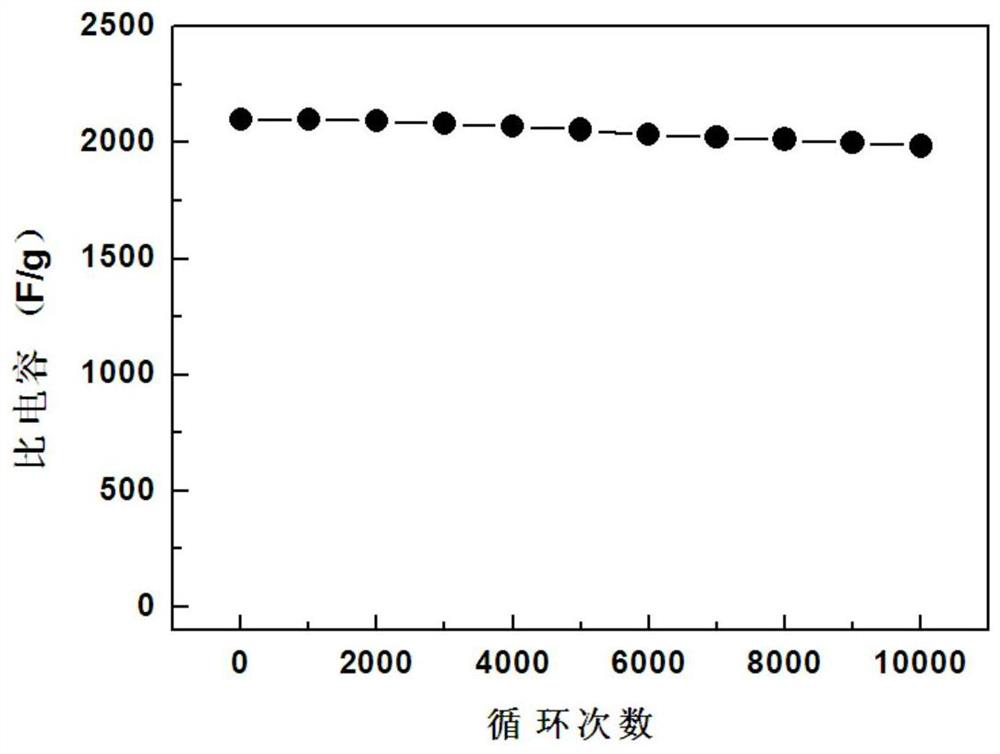

A kind of znsn nanowire material and preparation method thereof for supercapacitor

A technology of supercapacitors and nanowires, applied in the manufacture of hybrid/electric double layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of low energy density and power density, achieve simple equipment, realize large-scale industrial production, and unique electrochemical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) The double-temperature zone horizontal tube furnace is used as the growth equipment; the quartz is used as the substrate, placed at the lower air flow end of the horizontal tube furnace; ZnO powder with a purity of more than 99.99% is used as the raw material, and placed at the upper air flow end of the horizontal tube furnace ;

[0024] 2) The horizontal tube furnace is evacuated until the background vacuum degree is lower than 1.5Pa, and then the horizontal tube furnace is heated. The temperature of the raw material area is 900°C, and the temperature of the substrate area is 500°C;

[0025] 3) First feed H2S through a gas pipeline, the gas flow rate is 12 sccm, and react for 5 minutes; then feed NH3, the gas flow rate is 12 sccm, and keep the H2S feed in step 2) while feeding NH3, and the NH3 gas flow rate is the same as The H2S gas flow rate in step 2) is the same, and reacted in the H2S-NH3 mixed atmosphere for 20min;

[0026] 4) After the reaction, turn off the...

Embodiment 2

[0032] 1) The double-temperature zone horizontal tube furnace is used as the growth equipment; the quartz is used as the substrate, placed at the lower air flow end of the horizontal tube furnace; ZnO powder with a purity of more than 99.99% is used as the raw material, and placed at the upper air flow end of the horizontal tube furnace ;

[0033] 2) The horizontal tube furnace is evacuated until the background vacuum degree is lower than 1.5Pa, and then the horizontal tube furnace is heated. The temperature of the raw material area is 900°C, and the temperature of the substrate area is 500°C;

[0034] 3) First feed H2S through a gas pipeline, the gas flow rate is 14 sccm, and react for 5 minutes; then feed NH3, the gas flow rate is 14 sccm, and keep the H2S feed in step 2) while feeding NH3, and the NH3 gas flow rate is the same as The H2S gas flow rate in step 2) is the same, and reacted in the H2S-NH3 mixed atmosphere for 20min;

[0035] 4) After the reaction, turn off the...

Embodiment 3

[0040] 1) The double-temperature zone horizontal tube furnace is used as the growth equipment; the quartz is used as the substrate, placed at the lower air flow end of the horizontal tube furnace; ZnO powder with a purity of more than 99.99% is used as the raw material, and placed at the upper air flow end of the horizontal tube furnace ;

[0041] 2) The horizontal tube furnace is evacuated until the background vacuum degree is lower than 1.5Pa, and then the horizontal tube furnace is heated. The temperature of the raw material area is 900°C, and the temperature of the substrate area is 500°C;

[0042] 3) First feed H2S through a gas pipeline, the gas flow rate is 16 sccm, and react for 5 minutes; then feed NH3, the gas flow rate is 16 sccm, and keep the H2S feed in step 2) while feeding NH3, and the NH3 gas flow rate is the same as The H2S gas flow rate in step 2) is the same, and reacted in the H2S-NH3 mixed atmosphere for 20min;

[0043] 4) After the reaction, turn off the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com