Composite catalyst based on conjugated microporous polymer, and preparation method and application thereof

A technology of composite catalysts and conjugated micropores, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as poor hydrophobic performance and poor restart performance , to achieve the effect of good radiation resistance, improved life and restart performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

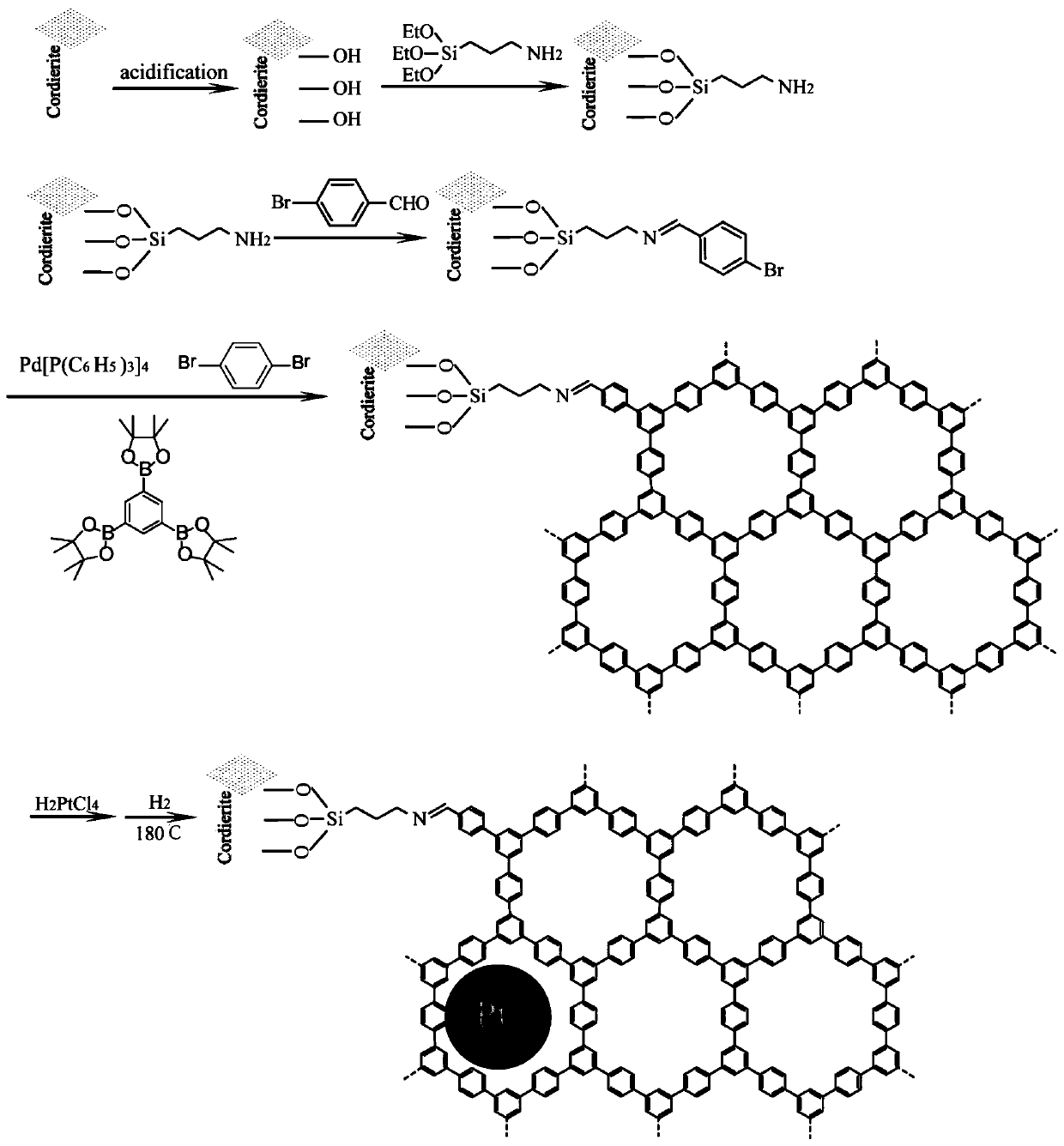

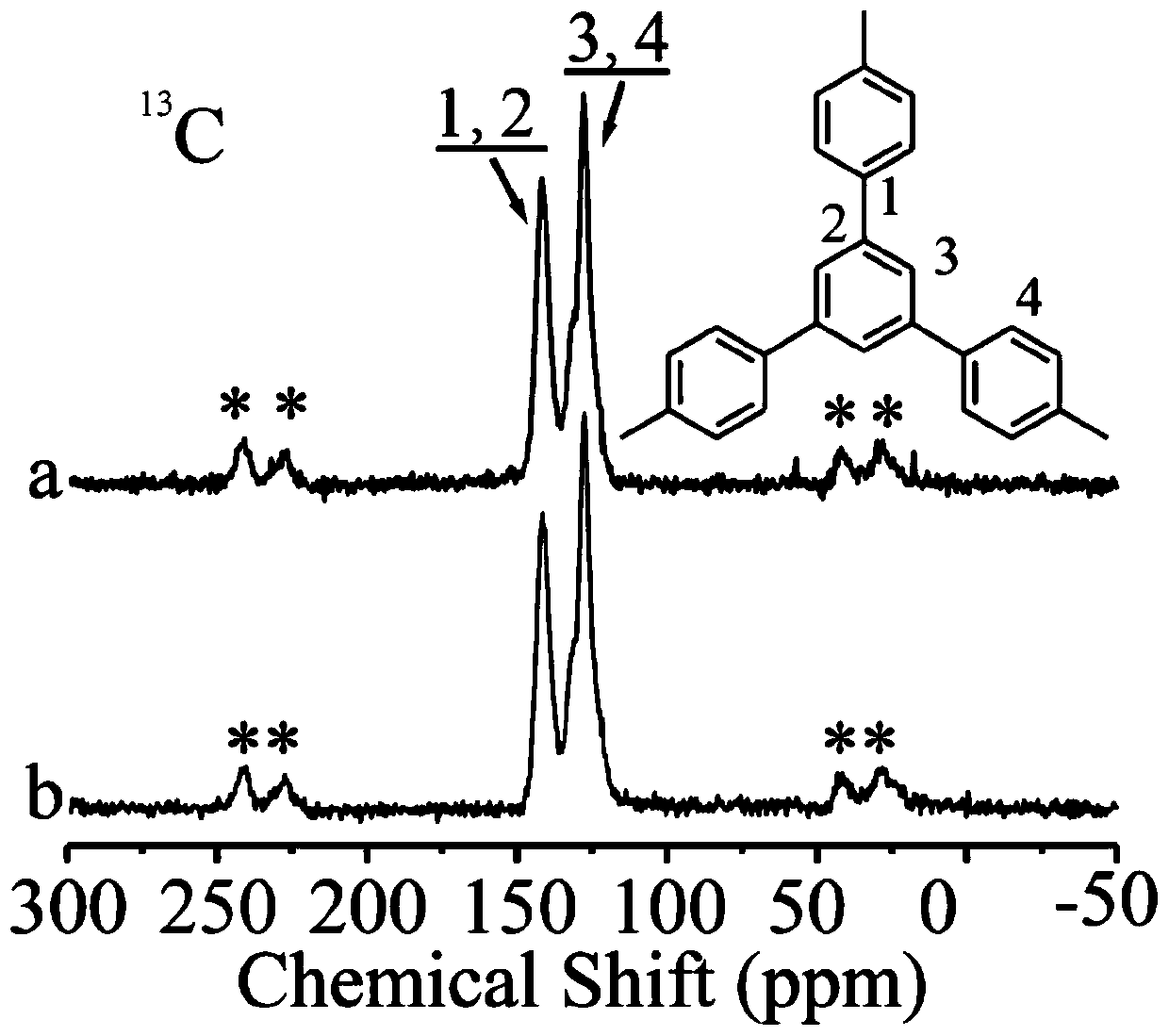

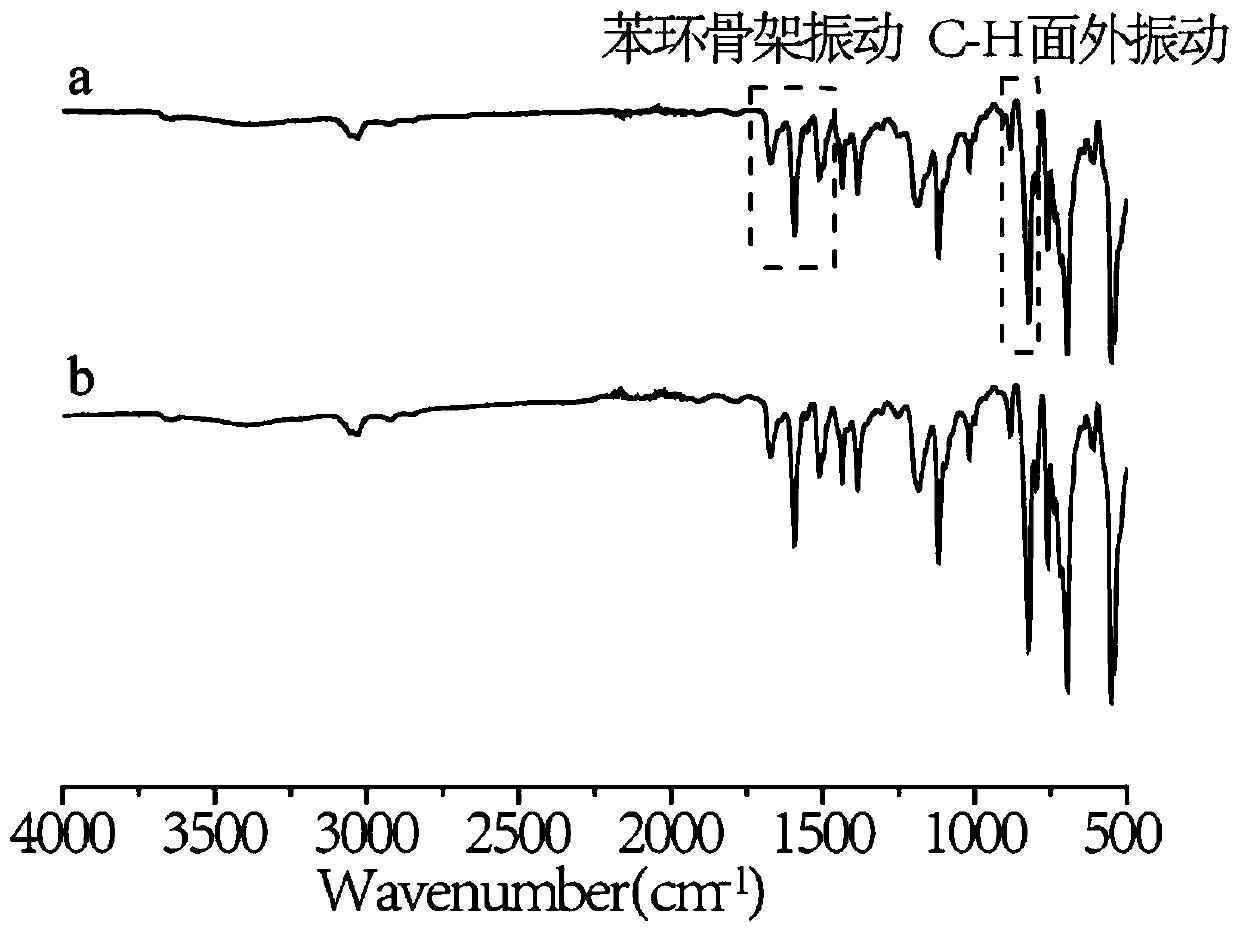

[0058] This example provides a conjugated microporous polymer-cordierite as a carrier and a Pt-loaded conjugated microporous polymer composite catalyst and its preparation method. The schematic diagram of the reaction route is as follows figure 1 Shown, the reaction steps are as follows:

[0059] (a) Acidification: Divide the cordierite into a cylindrical shape with a diameter of 20 mm and a diameter of 14 mm. The cross-section is honeycomb-shaped, and each cordierite weighs about 1.2727 g. Soak the cordierite in 20% nitric acid and shake it on a shaker for 24 hours. After 24 hours, the cordierite was washed with deionized water until the water was neutral, and then dried in a vacuum oven at 120° C. for 12 hours to obtain acidified cordierite.

[0060] (b) Ammonification: add 33g acidified cordierite and 250mL anhydrous toluene to the reaction flask, dissolve 30mL KH550 in 20mL anhydrous toluene, add dropwise to the reaction flask within four hours, and reflux at 80°C for 24h...

Embodiment 2

[0069] This example provides a hydrogen catalytic oxidation experiment of a composite catalyst of a conjugated microporous polymer. Hydrogen is an isotope of tritium, and its properties are similar to it. Therefore, the catalytic oxidation performance of the composite catalyst of the present invention for tritium can be obtained. The pressure drop of the honeycomb catalyst is 1-2 orders of magnitude lower than that of the granular catalyst, and it has a better amplification effect, which can greatly improve the processing capacity of the tritium removal system. In order to test the catalytic performance and gas handling capacity of the material, this embodiment tested the catalytic oxidation performance of the composite catalyst for hydrogen at different temperatures, initial hydrogen concentrations and space velocities. Methods as below:

[0070] Dry air and air containing 10% hydrogen are used as the processing gas, and the flow rate and hydrogen concentration of air and hyd...

Embodiment 3

[0074] This example provides the restart performance of the composite catalyst of the conjugated microporous polymer. The catalyst is placed in the hydrogen monitoring system, and the initial concentration of hydrogen is 1000ppm, and the flow rate is 0.3L min -1 , temperature 30°C and space velocity 3000h -1 , under the condition that the material volume is 6mL, by controlling the flow time of hydrogen in the system, the catalyst is catalyzed in hydrogen for two hours and then the catalyst is suspended for two hours. Repeat this operation 5 times to test the restart performance of the material. Experimental results Figure 10 shown. Figure 10 (A) and (B) respectively show the effects of Pt-CMPI@C3 continuous catalysis for 12 h and 5 times of start and stop on the conversion efficiency of the catalyst. The results showed that the hydrogen catalytic ability of the Pt-CMPI@C3 composite catalyst remained above 99.6% without significant decline after 12 hours of continuous opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com