Preparation method of artificial timber for generating negative oxygen ions like living standing stock

A negative oxygen ion and wood technology, applied in the field of wood bionics, can solve the problems of single function and low added value, achieve broad application prospects and increase added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

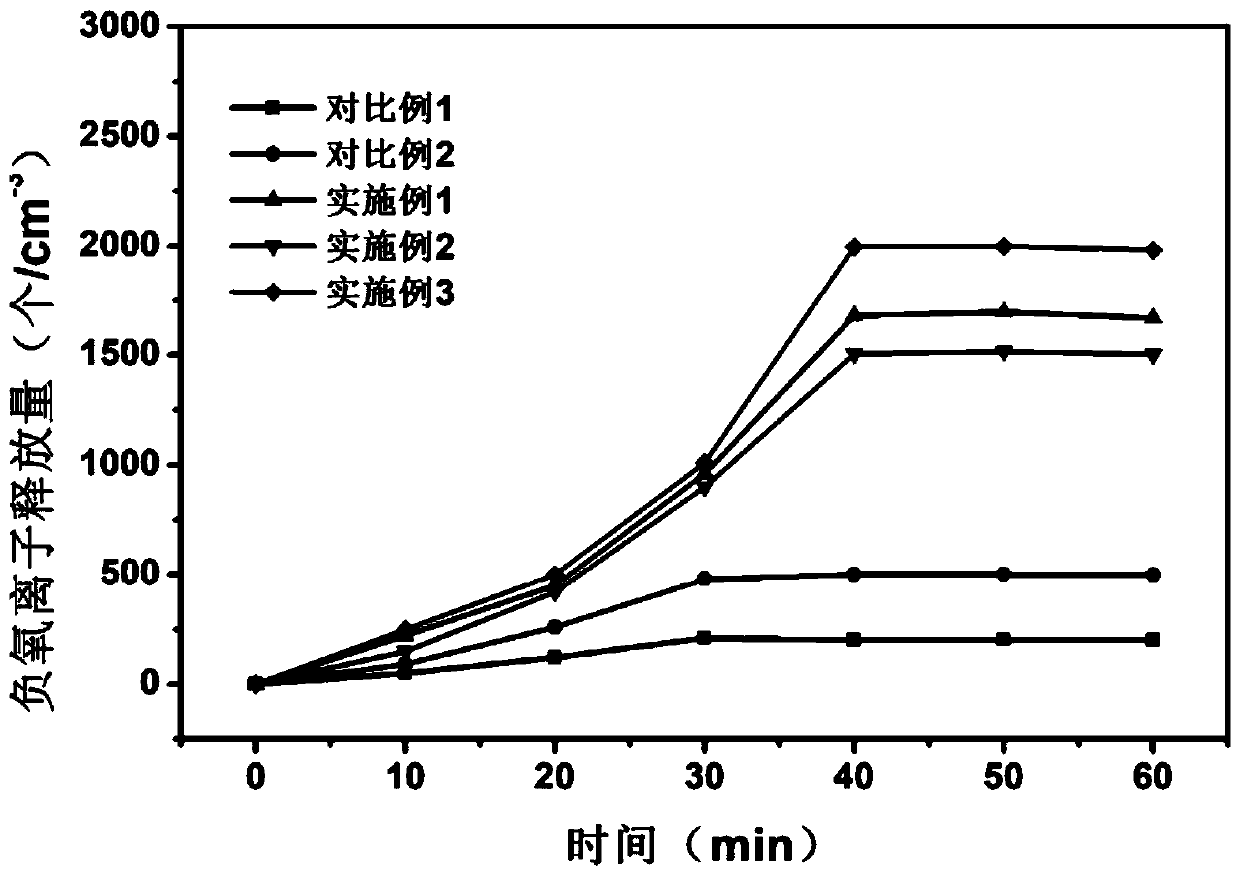

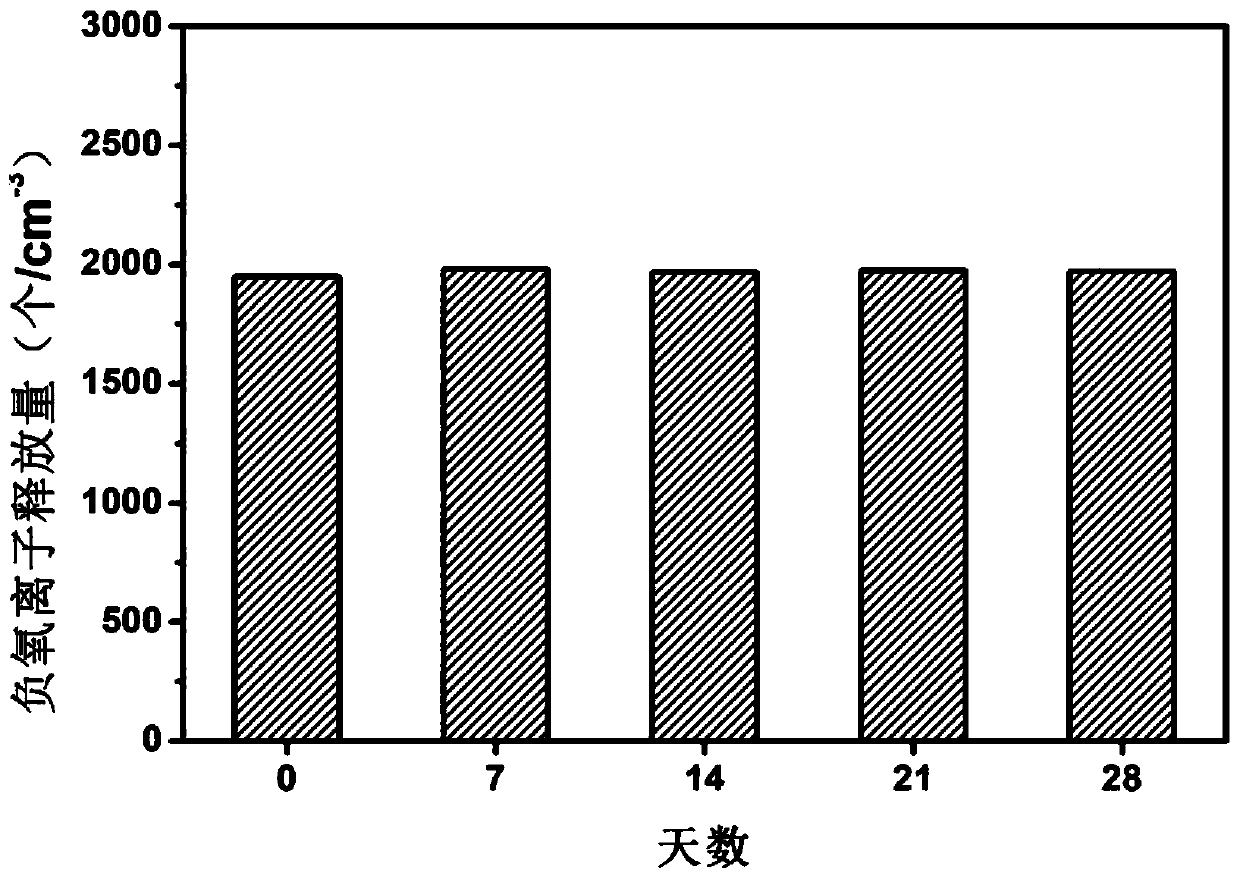

Examples

Embodiment 1

[0047] S101: Dissolve 100 g of sodium hydroxide and 50 g of sodium sulfite in 1000 mL of deionized water to prepare a sodium hydroxide / sodium sulfite aqueous solution, wherein the concentration of sodium hydroxide is 2.5 mol / L, and the concentration of sodium sulfite is 0.4 mol / L;

[0048] S102: heating the sodium hydroxide / sodium sulfite aqueous solution to 100°C, immersing the wood in it for cooking for 7 hours;

[0049] S103: putting the cooked wood into deionized water, and heating to 100° C. to remove residual reagents in the wood;

[0050] S201: Put 30g of melamine into the crucible and treat it at 550°C for 4 hours;

[0051] S202: After the product of S201 is cooled to room temperature, it is dispersed in concentrated hydrochloric acid and settled for 24 hours, and the precipitated particles are collected after centrifugation;

[0052] S203: Wash the precipitated particles in step S202 with deionized water and dry in an oven to obtain the g-C3 N 4 ;

[0053] S301: Mi...

Embodiment 2

[0062] S101: Dissolve 0.4 g of sodium hydroxide and 1.26 g of sodium sulfite in 1000 mL of deionized water to prepare a sodium hydroxide / sodium sulfite aqueous solution, wherein the concentration of sodium hydroxide is 0.01 mol / L, and the concentration of sodium sulfite is 0.01 mol / L;

[0063] S102: heating the sodium hydroxide / sodium sulfite aqueous solution to 100°C, immersing the wood in it for 0.1h;

[0064] S103: putting the cooked wood into deionized water, and heating to 100° C. to remove residual reagents in the wood;

[0065] S201: Put 1 g of melamine into a crucible and treat it at 550°C for 4 hours;

[0066] S202: After the product of S201 is cooled to room temperature, it is dispersed in concentrated hydrochloric acid and settled for 24 hours, and the precipitated particles are collected after centrifugation;

[0067] S203: Wash the precipitated particles in step S202 with deionized water and dry in an oven to obtain the g-C 3 N 4 ;

[0068] S301: Mix 1.985g of...

Embodiment 3

[0077] S101: Dissolve 200 g of sodium hydroxide and 378 g of sodium sulfite in 1000 mL of deionized water to prepare a sodium hydroxide / sodium sulfite aqueous solution, wherein the concentration of sodium hydroxide is 5 mol / L, and the concentration of sodium sulfite is 3 mol / L;

[0078] S102: heating the sodium hydroxide / sodium sulfite aqueous solution to 100°C, soaking the wood in it for cooking for 48 hours;

[0079] S103: putting the cooked wood into deionized water, and heating to 100° C. to remove residual reagents in the wood;

[0080] S201: Put 100g of melamine into the crucible and treat it at 550°C for 4 hours;

[0081] S202: After the product of S201 is cooled to room temperature, it is dispersed in concentrated hydrochloric acid and settled for 24 hours, and the precipitated particles are collected after centrifugation;

[0082] S203: Wash the precipitated particles in step S202 with deionized water and dry in an oven to obtain the g-C 3 N 4 ;

[0083] S301: Mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com