Fluorescent glass ceramic based on low-melting-point glass powder and preparation method thereof

A technology of low-melting glass and fluorescent glass, which is applied in the field of special glass production and manufacturing, can solve the problems of PbO that is harmful to human health, thermal degradation of phosphor materials, and high light scattering loss, and achieve good structural stability and chemical stability. Effect of reducing light scattering loss and avoiding thermal deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

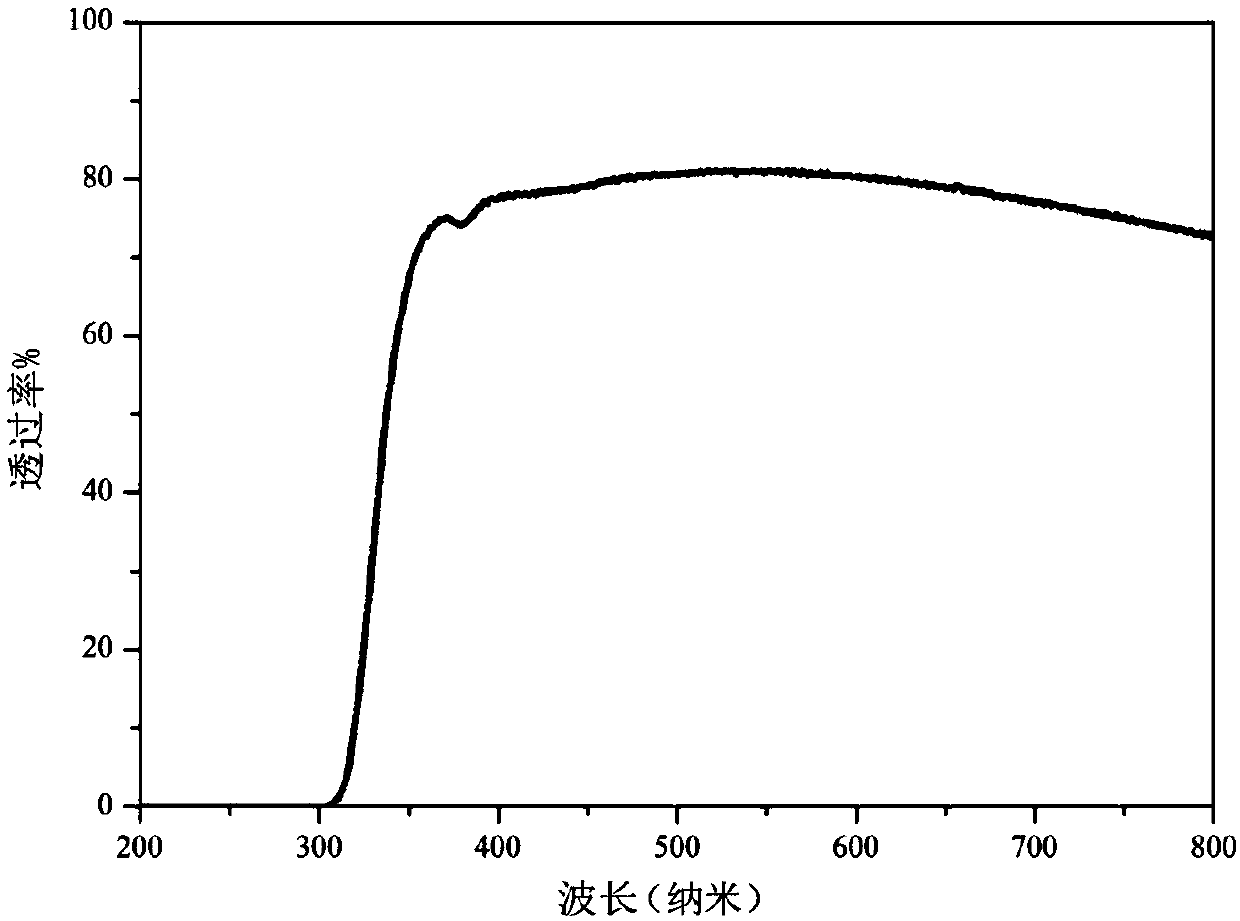

[0047] A preparation method of fluorescent glass ceramics, comprising the following steps:

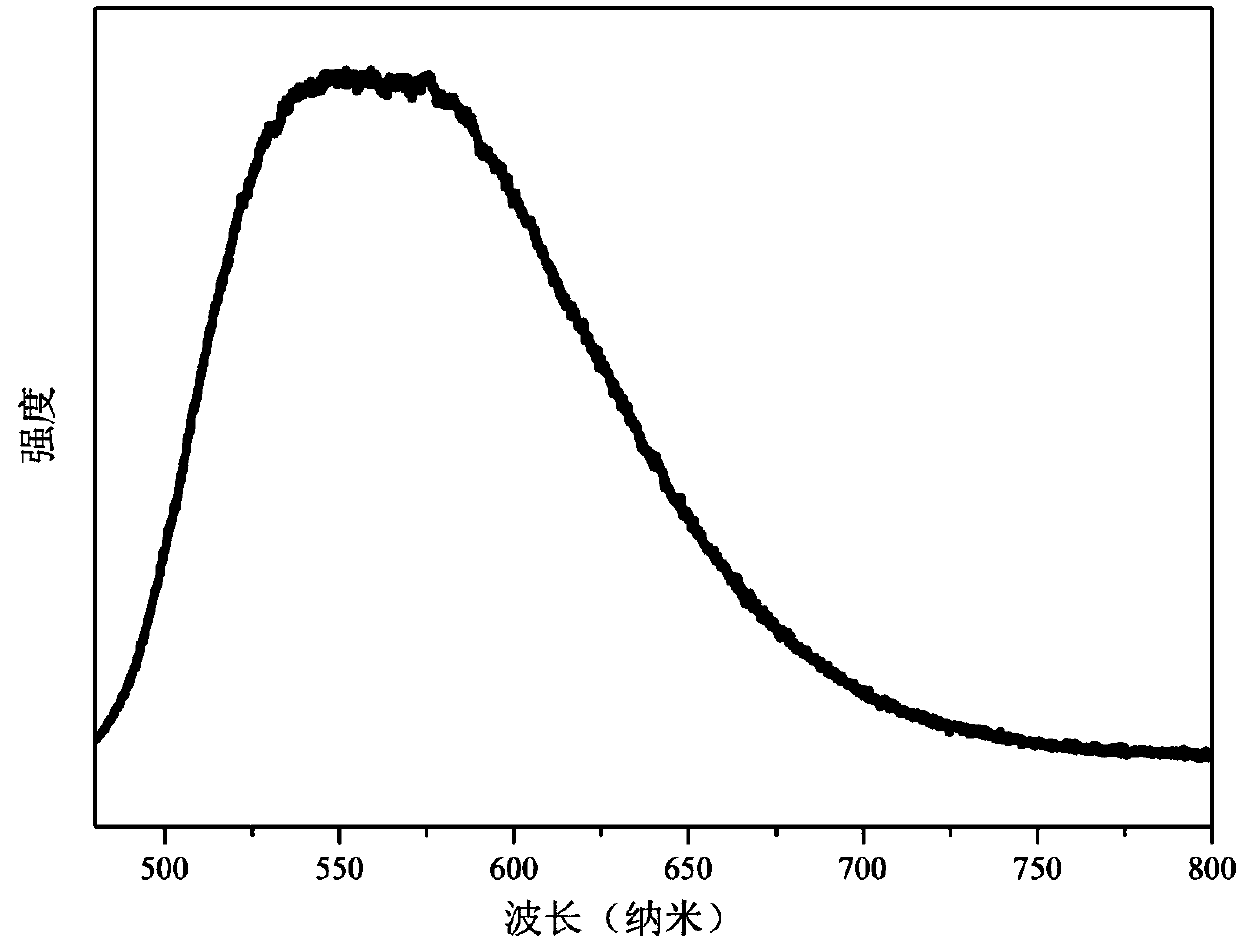

[0048] 1) In terms of mass percentage, 70wt% of low-melting glass powder and 30wt% of phosphor powder (YAG: Ce 3+ Yellow fluorescent powder) after mixing, realize uniform mixing by ball milling for 4 hours to obtain a preliminary mixture, wherein ethanol is used as the medium of ball milling;

[0049] 2) Press the preliminary mixture obtained in step 1) into thin slices with a thickness of 2mm, the pressure of the pressed thin slices is 10MPa, and the thin slices are calcined in a microwave oven for 5 minutes to obtain fluorescent glass ceramics. The scanning calorimeter measures the phase transition temperature of the low-melting point glass powder to be 270°C, and the temperature of calcination in the microwave oven is 30°C higher than the phase transition temperature of the low-melting point glass powder (that is, the calcination temperature is 300°C);

[0050] Wherein, the prepara...

Embodiment 2

[0055] A preparation method of fluorescent glass ceramics, comprising the following steps:

[0056] 1) In terms of mass percentage, 90wt% of low-melting glass powder and 10wt% of phosphor powder (YAG: Ce 3+ Yellow fluorescent powder) after mixing, realize uniform mixing by ball milling for 5 hours to obtain a preliminary mixture, wherein ethanol is used as the medium of ball milling;

[0057] 2) Press the preliminary mixture obtained in step 1) into a thin slice with a thickness of 3 mm, the pressure of the pressed thin slice is 10 MPa, and the thin slice is calcined in a microwave oven for 10 minutes to obtain fluorescent glass ceramics. The phase transition temperature of the low-melting point glass powder measured by the calorimeter is 330°C, and the calcination temperature is 30°C higher than the phase transition temperature of the low-melting point glass powder, that is, the calcination temperature is 360°C;

[0058] Wherein, the preparation method of low melting point g...

Embodiment 3

[0061] A preparation method of fluorescent glass ceramics, comprising the following steps:

[0062] 1) In terms of mass percentage, 80wt% of low-melting glass powder (with a particle size of 3-10 microns) and 20wt% of fluorescent powder (CaAlSiN 3 : Eu 2+ Red fluorescent powder) after mixing, achieve uniform mixing by ball milling for 6 hours to obtain a preliminary mixture, wherein ethanol is used as the medium of ball milling;

[0063] 2) Press the preliminary mixture obtained in step 1) into a thin slice with a thickness of 2.5 mm, the pressure of the pressed thin slice is 14 MPa, and the thin slice is calcined in a microwave oven for 15 minutes to obtain a fluorescent glass ceramic, and the Q2000 differential scanning method of the American TA Instrument Company is adopted. The calorimeter measures the phase transition temperature of the low-melting point glass powder to be 370°C, and the calcining temperature is 30°C higher than the phase transition temperature of the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com