Method for transforming dry-method rotary kiln cement plant and consuming ardealite to make building gypsum powder

A construction gypsum powder and cement plant technology, applied in the field of construction gypsum powder manufacturing, can solve the problems of large negative impact on hydration performance and strength, and achieve the effects of high degree of automation, high production capacity of process equipment, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

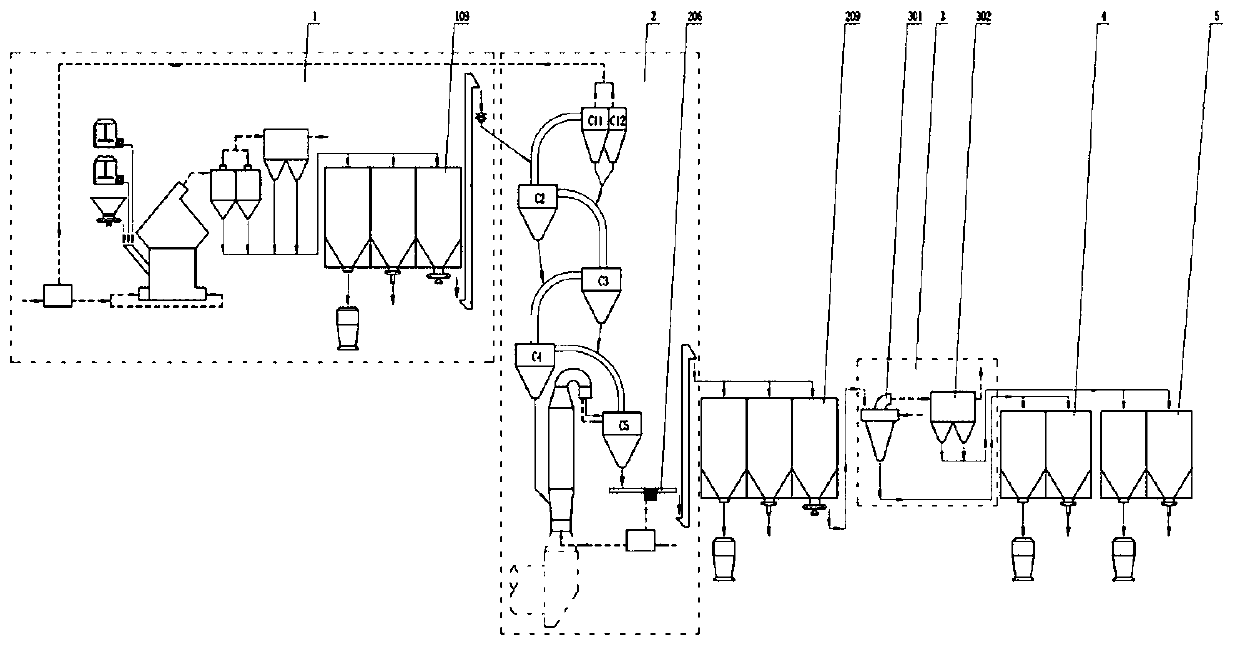

Image

Examples

Embodiment 1

[0032] In this example, phosphogypsum that has been completely solidified and agglomerated in the open-air storage yard of a phosphorus chemical company is selected, and it is pre-broken to a granular material with a particle size of 40mm or less. The content of gypsum fluctuates between 83.7% and 92.5%. Using this phosphogypsum to make building gypsum powder includes the following steps:

[0033] (1) Continuously feed the water-containing block granular phosphogypsum into the vertical mill of the phosphogypsum dry powder system, the temperature of the hot air entering the mill is 170°C±10°C, and the feeding amount of phosphogypsum is adjusted at 140-180t / h to make the <1.5% dry powder;

[0034] (2) Convey the dry powder into the dry powder storage, and the dry powder in the dry powder storage is continuously metered and transported into the dehydration system through the bottom discharge of the storage. Etching or coking away organic impurities to make dehydrated gypsum powd...

Embodiment 2

[0040] In this example, fresh phosphogypsum bulk material from a chemical company is selected, which is gray in color. The detected moisture content fluctuates from 22.1 to 26.8%, and the (dry basis) dihydrate gypsum content fluctuates from 86.8 to 94.5%. Using this phosphogypsum to make building gypsum powder, including The following steps:

[0041] (1) The water-containing bulk phosphogypsum is continuously fed into the vertical mill of the phosphogypsum dry powder production system, the temperature of the hot air entering the mill is adjusted at 270°C±10°C, the feeding amount of phosphogypsum is adjusted at 130-170t / h, and the lime milk The added amount accounts for 1.8% of the mass ratio of water-containing phosphogypsum, and it is made into a dry powder with a moisture content of <2%;

[0042] (2) Convey the dry powder into the dry powder storage. The dry powder in the dry powder storage is continuously metered and transported to the dehydration system through the dischar...

Embodiment 3

[0048] In this example, the washed phosphogypsum bulk material from a storage yard of a phosphogypsum washing factory is selected. Construction gypsum powder, comprising the following steps:

[0049] (1) The water-containing bulk phosphogypsum is continuously fed into the vertical mill of the phosphogypsum dry powder production system, the temperature of the hot air entering the mill is 250°C±10°C, the feeding amount of phosphogypsum is adjusted at 115-130t / h, and the water content is 1.0% dry powder;

[0050] (2) The dry powder is transported into the dry powder warehouse. The dry powder in the dry powder warehouse is continuously metered and transported into the dehydration system through the bottom discharge of the warehouse. The dry powder feed rate is adjusted at 110-130t / h, and the temperature range is controlled at 380°C±10°C for rapid dehydration, and ablation or coking of organic impurities. Make dehydrated gypsum powder whose crystal water content fluctuates betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com