Antibacterial composite material for coating and preparation method

A technology of composite materials and coatings, which is applied in the field of composite materials for coatings, can solve the problems that shells cannot be directly applied, ignore the loading performance of shell powder, etc., and achieve the goal of improving quantum efficiency and photocatalytic performance, improving loading performance, and improving performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

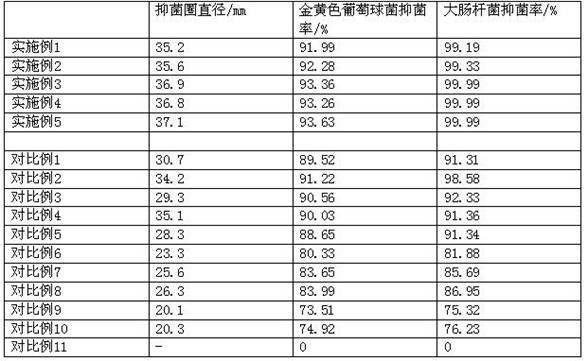

Examples

Embodiment 1

[0021] Step 1. Grind the shells of rock oysters that have grown for 3-5 years in Kumamoto Prefecture, Japan, and fully grind and screen to obtain shell powder of 800 mesh to 1250 mesh and shell powder of more than 2500 mesh, and the rest of the shell powder does not meet the requirements Flow stagnation in the next batch of shells for uniform grinding;

[0022] Step 2. Separately calcine and modify the shell powder of 800 mesh to 1250 mesh and the shell powder of more than 2500 mesh, specifically calcining in an aerobic environment at 500°C for 20 minutes to obtain the modified shell powder; the modified shell powder Add it to the citric acid solution with a concentration of 0.01mol / L and a pH value of 5.5. After ultrasonic dispersion, add it to an ultrasonic atomization device, and spray it into a high-temperature furnace at a temperature of 80-120°C through a high-pressure nozzle for spraying Dried to obtain surface carboxylated active shell powder;

[0023] Step 3. Add a c...

Embodiment 2

[0026] Step 1. Selected from Kumamoto Prefecture, Japan, the shells of rock oysters grown for 3-5 years are ground, fully ground and screened to obtain shell powder of 800 mesh to 1250 mesh and shell powder of more than 2500 mesh, and the rest of the shell powder does not meet the requirements. Stay in the next batch of shells for uniform grinding.

[0027] Step 2. Separately calcine and modify the shell powder of 800 mesh to 1250 mesh and the shell powder of more than 2500 mesh. Specifically, calcining in an aerobic environment at 500°C for 20 minutes to obtain modified shell powder, the modified shell The powder is added to a citric acid solution with a concentration of 0.01mol / L and a pH value of 5.5. After ultrasonic dispersion, it is added to an ultrasonic atomization device and sprayed into a high-temperature furnace at a temperature of 80-120°C through a high-pressure nozzle. Spray drying to obtain surface carboxylated active shell powder;

[0028] Step 3. Add a certai...

Embodiment 3

[0031] Step 1. Selected from Kumamoto Prefecture, Japan, the shells of rock oysters grown for 3-5 years are ground, fully ground and screened to obtain shell powder of 800 mesh to 1250 mesh and shell powder of more than 2500 mesh, and the rest of the shell powder does not meet the requirements. Stay in the next batch of shells for uniform grinding.

[0032] Step 2. Separately calcine and modify the shell powder of 800 mesh to 1250 mesh and the shell powder of more than 2500 mesh. Specifically, calcining in an aerobic environment at 400 ° C for 30 minutes to obtain modified shell powder, the modified shell powder Add it to a citric acid solution with a concentration of 0.01mol / L and a pH value of 6. After ultrasonic dispersion, add it to an ultrasonic atomization device, and spray it into a high-temperature furnace at a temperature of 80-120°C through a high-pressure nozzle for spraying Dried to obtain surface carboxylated active shell powder;

[0033] Step 3. Add a certain am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com