Zero discharge alkaline copper etching waste liquid recycling technology method

A technology of waste liquid recovery and process method, applied in the direction of process efficiency improvement, copper sulfate, etc., can solve the problems of large environmental pollution, long recycling process, large equipment investment, etc., to solve environmental pollution problems, reduce recycling costs, and treat high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

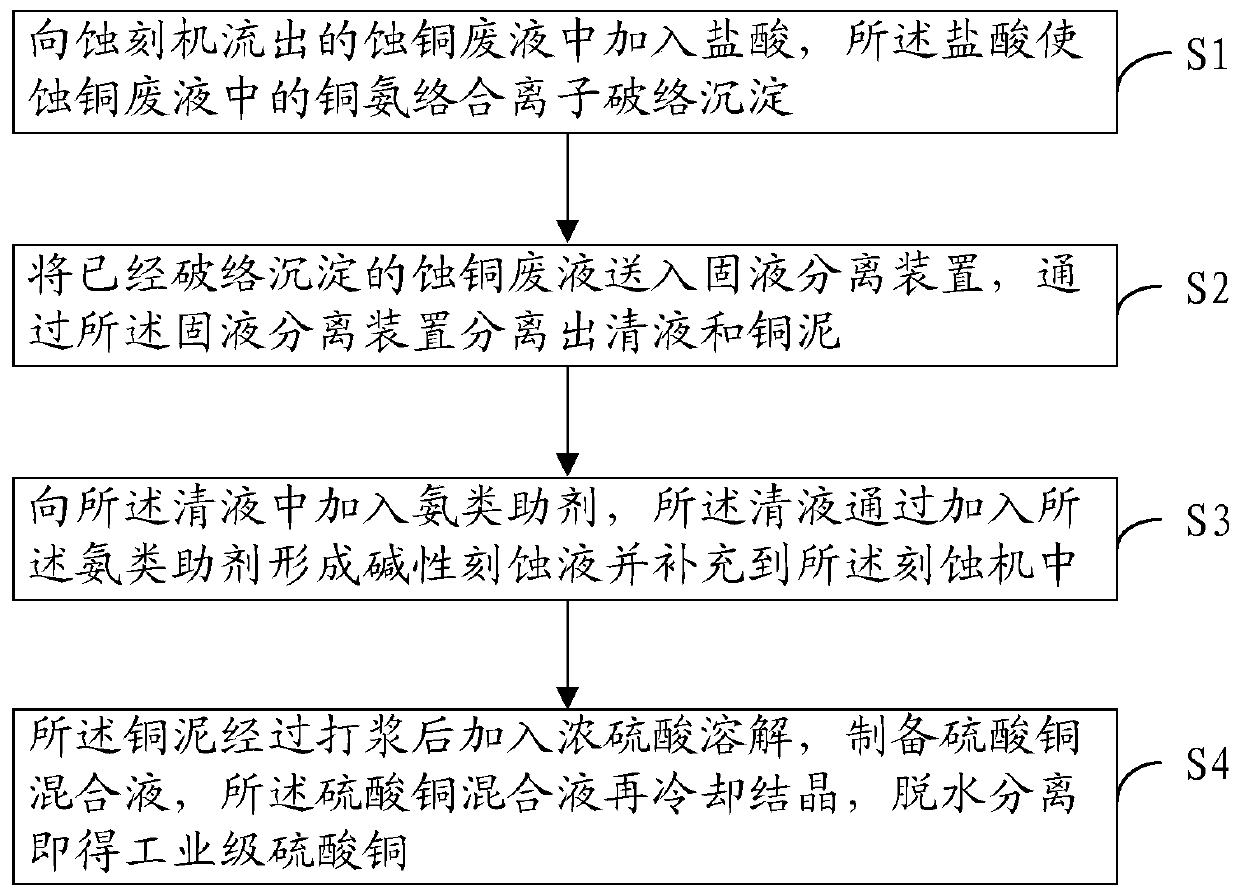

Image

Examples

Embodiment 1

[0051] (1) network breaking precipitation

[0052] Add hydrochloric acid to the copper etching waste liquid flowing out of the etching machine while stirring, and adjust the pH value of the copper etching waste liquid to 3.5-6.5 by hydrochloric acid, so that the copper ammonia complex ions in the copper etching waste liquid are broken and precipitated;

[0053] (2) Solid-liquid separation

[0054] Pump the copper-etching waste liquid that has broken and precipitated into the filter press, and the pump pressure of the filter press is 4.0kg / cm 2 , the clear liquid and copper mud are separated by the solid-liquid separation device, and the clear liquid is NH 4 Cl solution, the copper content of the copper mud is about 35%;

[0055] (3) Clear liquid recovery

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com